Multifunctional shoe storing and taking device based on comb type transportation

A multi-functional, comb-like technology, used in storage devices, transportation and packaging, household cleaning devices, etc., to achieve the effect of increasing the scope, expanding the way of use, and simplifying the way of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

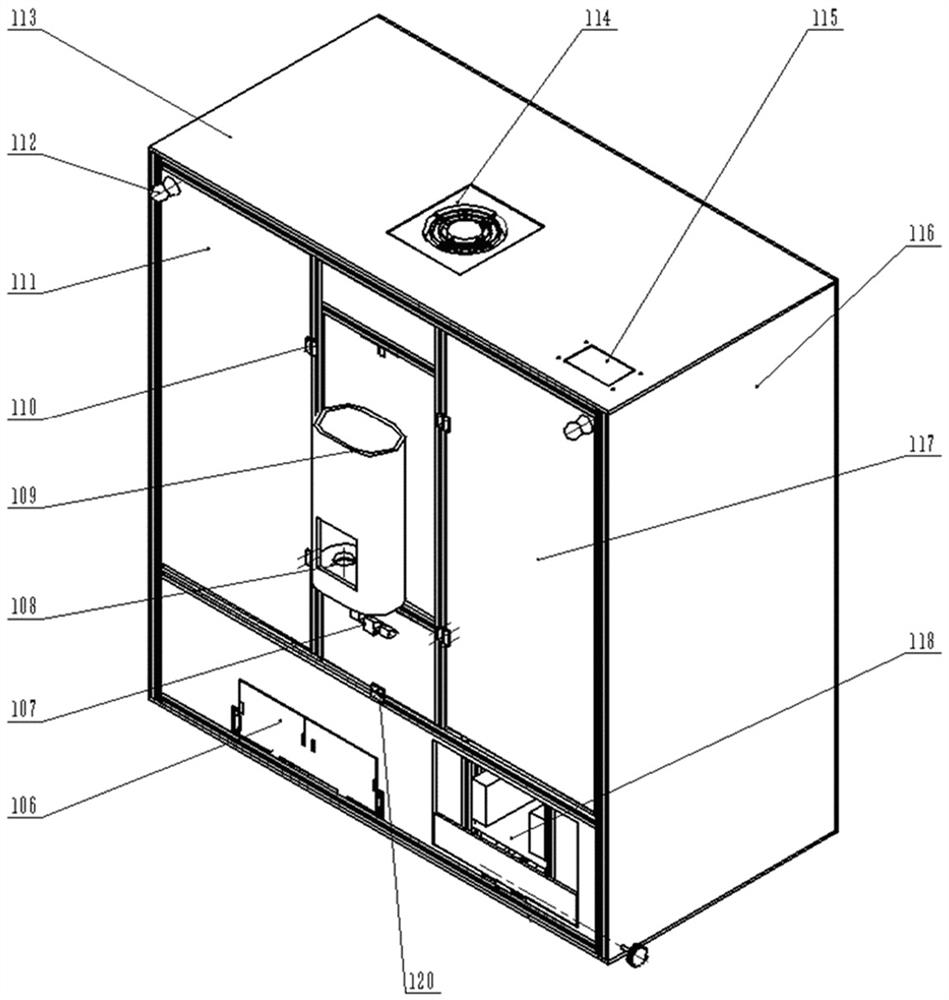

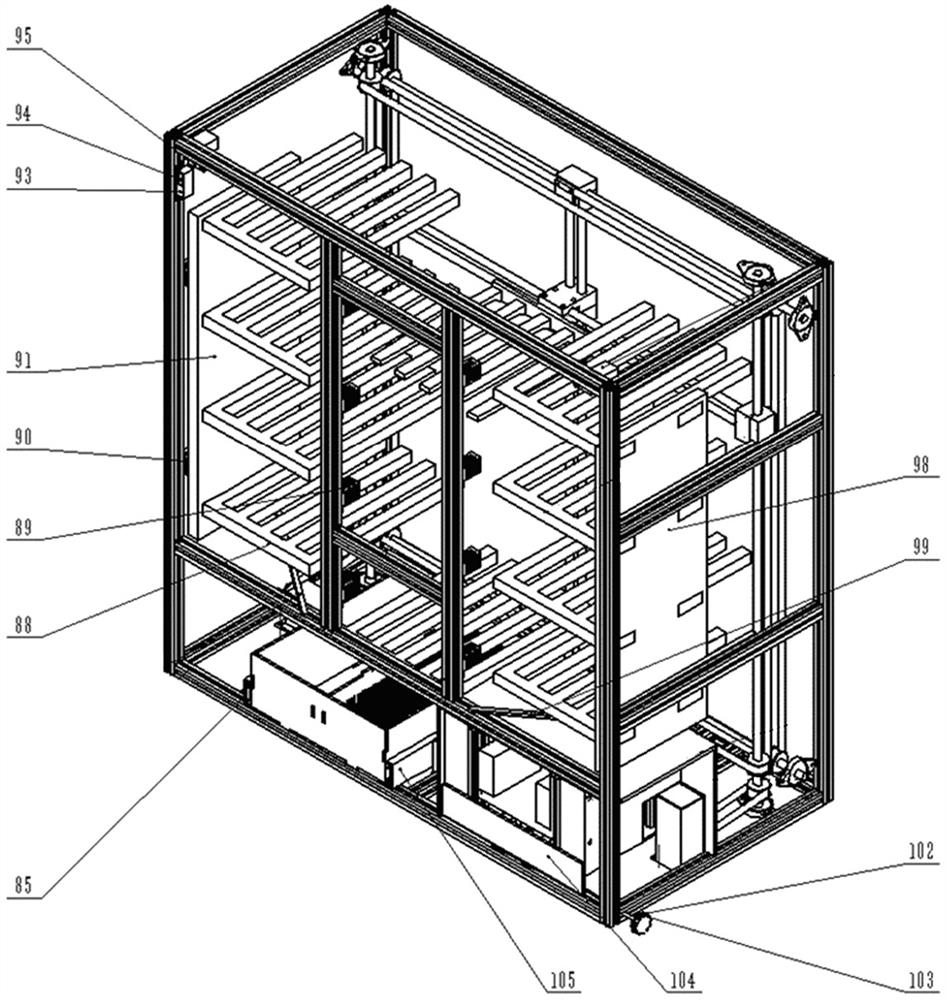

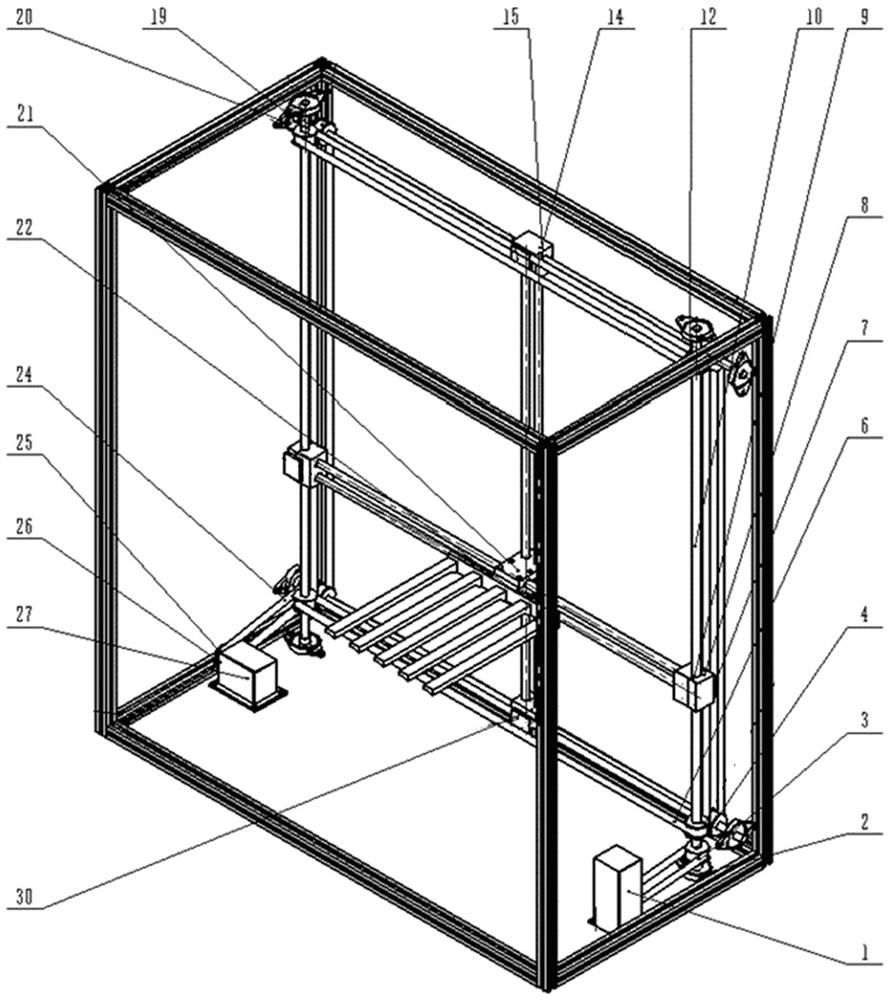

[0025] Such as figure 1 , figure 2 As shown, a multifunctional access shoe device based on comb-type transportation, including a cabinet body, a left shoe rack, a right shoe rack, an access shoe transmission device, a shoe access power device, a cleaning device, a wiper Shoe device 118, drying and disinfection device 114, control system, the cabinet body is a square box body mechanism composed of front vertical board, rear vertical board, left vertical board, right vertical board 116, top board 113 and bottom board, the front The upper left side of the vertical plate is provided with a left cabinet door 111 through the cabinet door hinge 110, and the left cabinet door 111 is provided with a cabinet door handle 112, and the left side shoe rack is provided at the position corresponding to the left cabinet door 111 in the cabinet, and the front vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com