A high load-bearing strong frame structure of a small waterplane area catamaran

A technology of small waterplane double-body and frame structure, which is applied in the direction of hull frame, hull, ship construction, etc., to achieve the effect of reducing stress level, improving fatigue strength, and improving overall load-carrying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

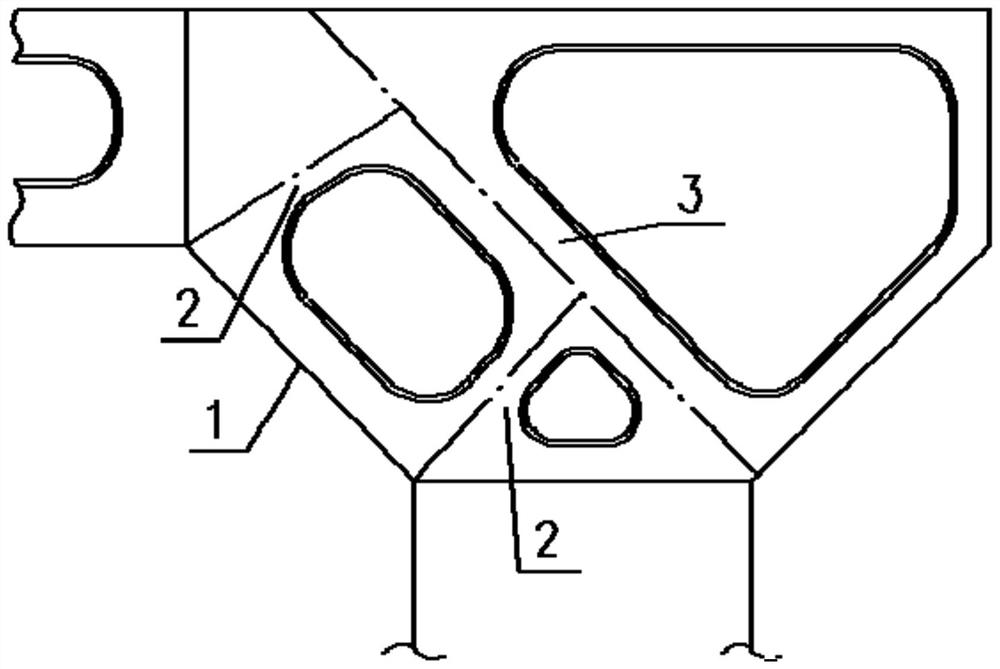

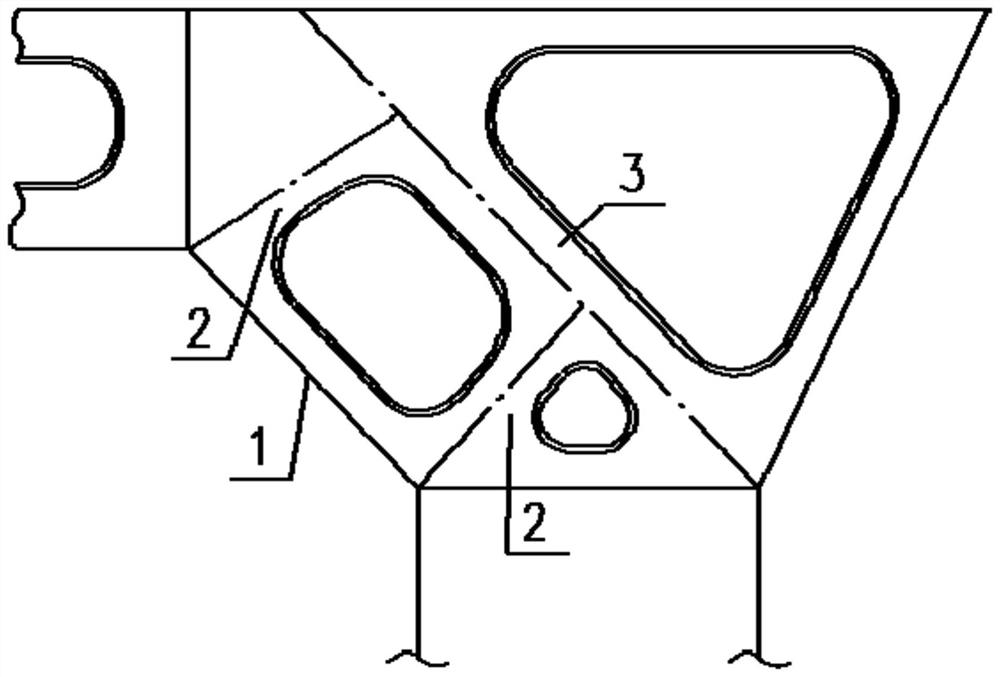

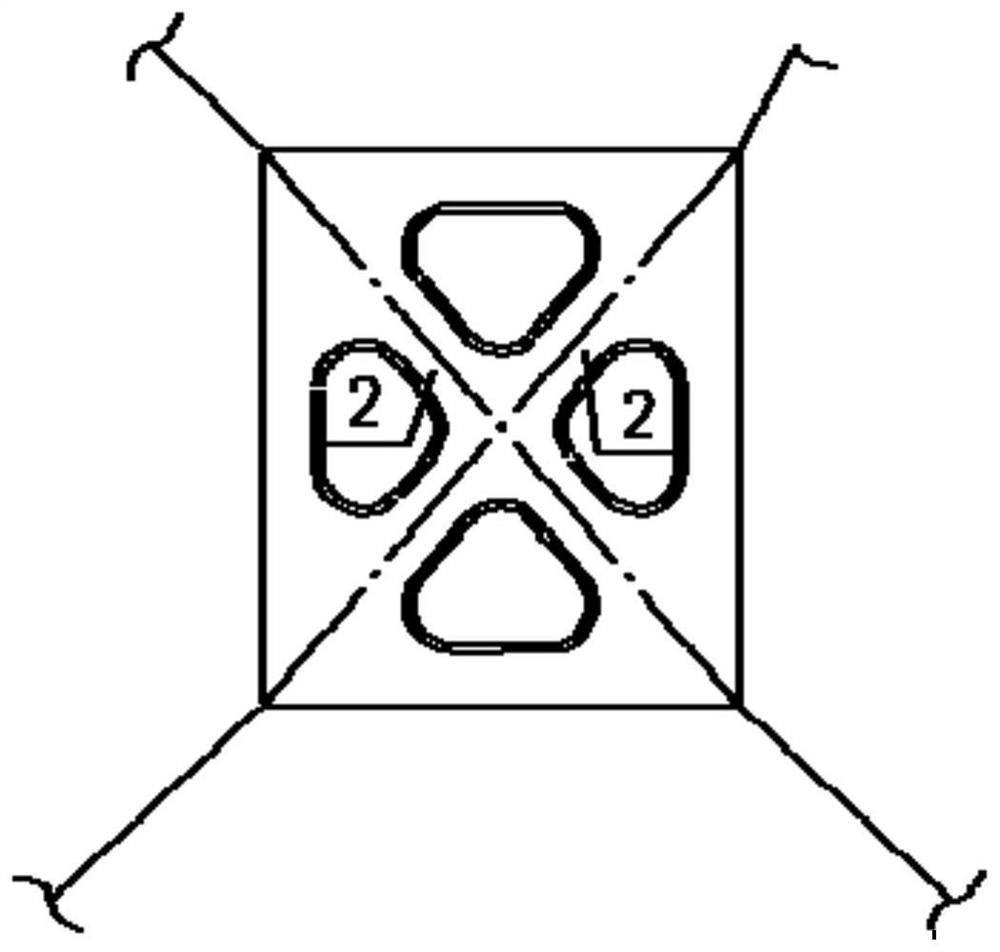

[0026] like Figure 1 to Figure 7 As shown, a small waterplane area catamaran high load-bearing strong frame structure is used in the field of small waterplane area catamaran hull structure design. Column 3 structure, and set several diagonal braces perpendicular to the frame. When two diagonal braces 2 are set, it is in the form of oblique "π", and the upper "horizontal" of the "π" type structure is the brace 3, which is connected with the stern The inner sloping plate 1 is roughly parallel, and the lower two "verticals" are slanting braces 2, which are perpendicular to the sloping plate 1 on the inner side of the sloping platform. Except for the "π" type structure, the other strong frame structures in the sloping platform area can adopt conventional forms and be connected with The "π"-shaped structures are integrated into one, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com