An automatic packaging system for graphite heaters

A graphite heater and automatic packaging technology, which is applied in the direction of pressurized/vaporized packaging, packaging, electric heating devices, etc., can solve the problems of difficulty, easy breakage of electrodes, and easy breakage of products, so as to reduce the force on the edge The effect of size, avoiding excessive size of the press, symmetrical and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

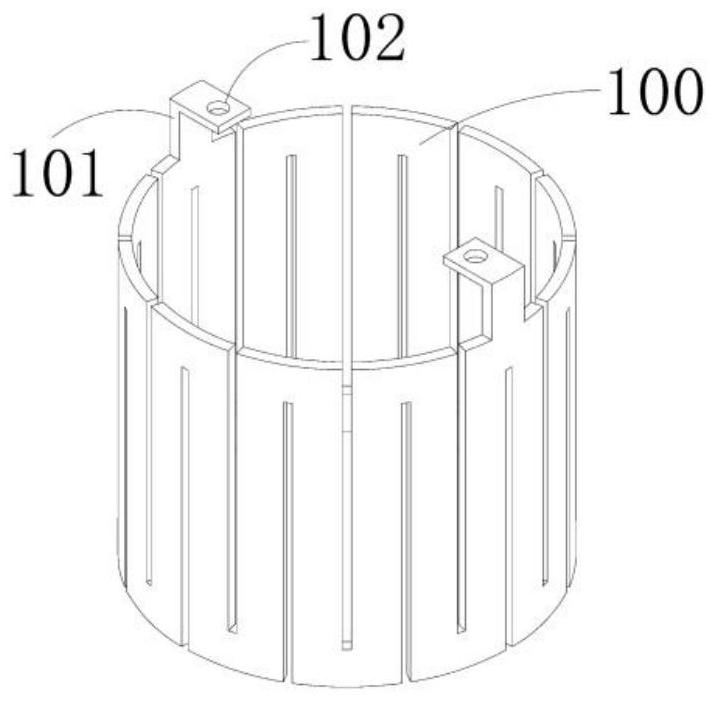

[0061] Such as Figure 4-9 Shown, a kind of automatic packing system with graphite heater, comprises rack 1, also comprises:

[0062] The first conveyor 2, the first conveyor 2 is used to transport the graphite heater 100 to be packaged;

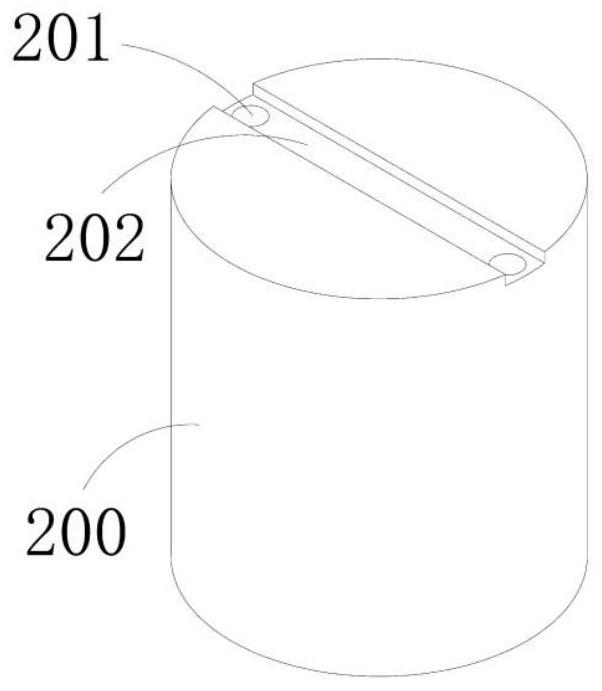

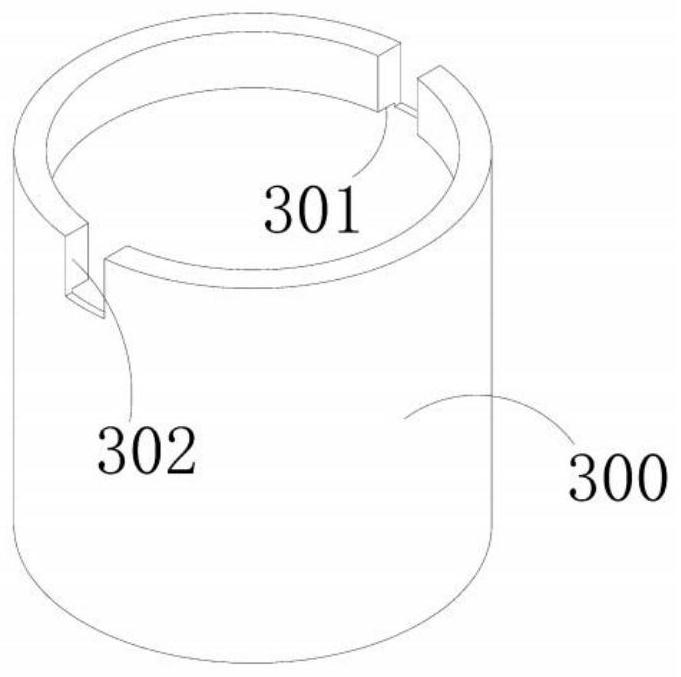

[0063] The second conveyor 3, the second conveyor 3 is used to transport the inner lining 200 and the outer lining 300;

[0064] The 3rd conveyer 4, described 3rd conveyer 4 is used for conveying the graphite heater 100 that packing is finished; One end side of described 3rd conveyer 4 is provided with packing workbench 41, and the both sides of packing workbench 41 are symmetrically arranged There is a guide bracket 411, a guide groove 4111 is provided on the guide bracket 411, a positioning groove 412 is provided on the bottom surface of the packaging workbench 41, and a groove-shaped opening 4121 is provided above the positioning groove 412;

[0065] Manipulator 5, described manipulator 5 is used for grabbing and moving graphite heater ...

Embodiment 2

[0086] Such as Image 6 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The advantage is that:

[0087] Such as Image 6 As shown, wherein, the manipulator 5 includes a horizontal rotation assembly 51, a vertical telescopic assembly 52 connected with the horizontal rotation assembly 51, a horizontal telescopic assembly 53 connected with the vertical telescopic assembly 52, and arranged on the The second connecting rod assembly 54 at one end of the horizontal telescopic assembly 53 and two clamps 55 symmetrically arranged at one end of the second connecting rod assembly 54 ; the shape of the clamps 55 is matched with the graphite heater 100 .

[0088] It should be noted that a rotating motor is provided at the bottom of the...

Embodiment 3

[0092] Such as Figure 18-20 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences between the first embodiment and the first embodiment are described below; the differences between the third embodiment and the first embodiment The difference is that:

[0093] Such as Figure 18 As shown, as an improvement, the first positioning channel 21 with a groove on the top is provided on the first conveyor 2, and the first positioning channel 21 matches the shape of the graphite heater 100; A second positioning channel 22 with a boss on the top is provided, and the second positioning channel 22 matches the shapes of the inner liner 200 and the outer liner 300 .

[0094] It should be noted that during transportation, the electrodes of the graphite heater are positioned and conveyed through the grooves opened on the top of the first positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com