Wire coil paying-off device and method

A wire pay-off device and wire reel technology, applied in the field of electric power, can solve the problems of non-universal use, low use efficiency, heavy pay-off device, etc., and achieve the effects of convenient carrying, reasonable design and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in conjunction with accompanying drawing and specific embodiment:

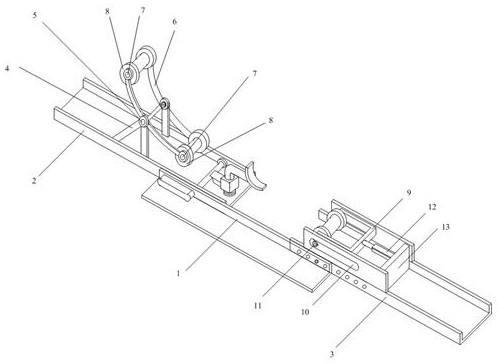

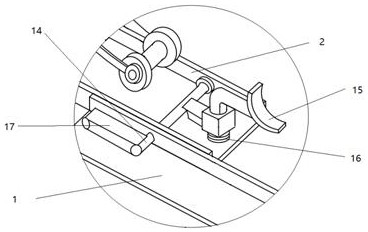

[0014] Such as Figure 1-2 As shown, a reel pay-off device includes connecting angle steel 1, fixed channel steel 2, movable channel steel 3, fixed bracket 4, rotating shaft A5, arc connecting arm 6, rotating shaft B7, concave pulley 8, U-shaped connection Rod 9, slide rail 10, rotating shaft C11, horizontal jack 12, support plate 13, characterized in that: the left side of the connecting angle steel 1 is welded to the fixed channel steel 2, and the right side of the connecting angle steel 1 is connected to the movable channel steel 3 through Bolt connection, the top of the fixed channel steel 2 is equipped with a fixed bracket 4, and the top of the fixed bracket 4 is equipped with an arc-shaped connecting arm 6 through the rotating shaft A5, and two rotating shafts B7 are symmetrically installed at both ends of the arc-shaped connecting arm 6 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com