Hollow slab beam inner mold convenient to disassemble and assemble

A technology of hollow slab girders and inner molds, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., which can solve the problems of inconvenient disassembly of inner molds and narrow space of inner molds, and achieve the effects of protecting safety and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-9 The application is described in further detail.

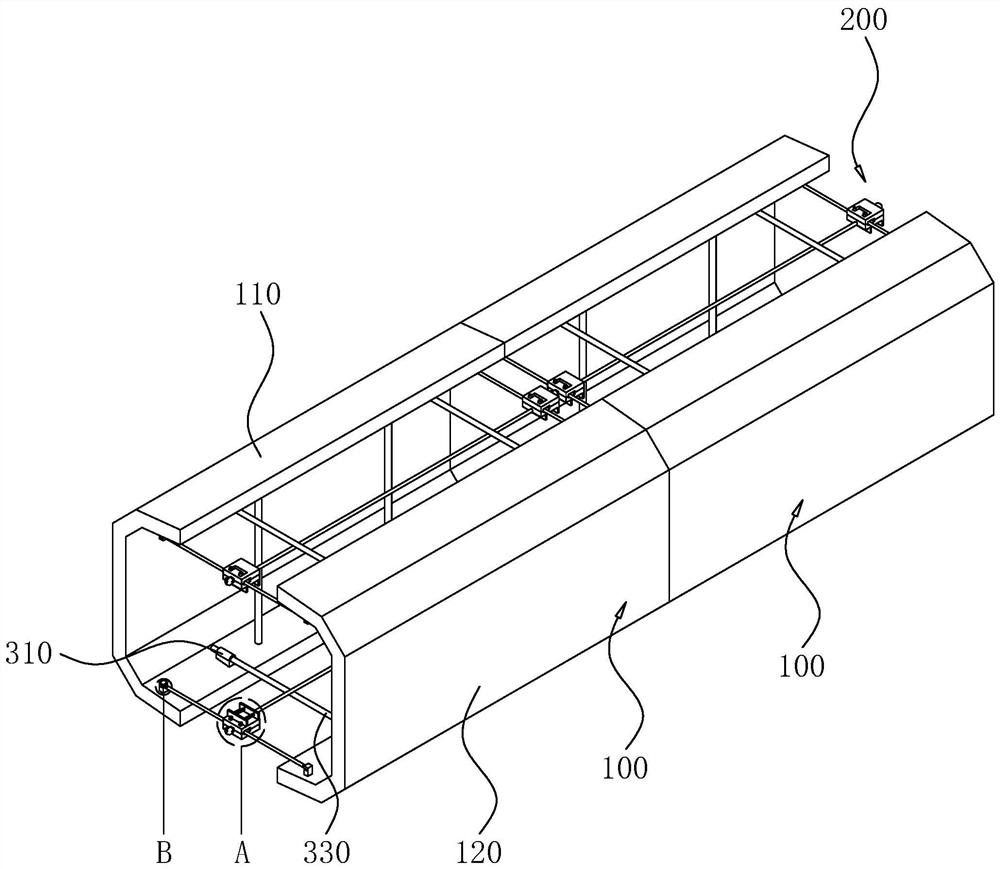

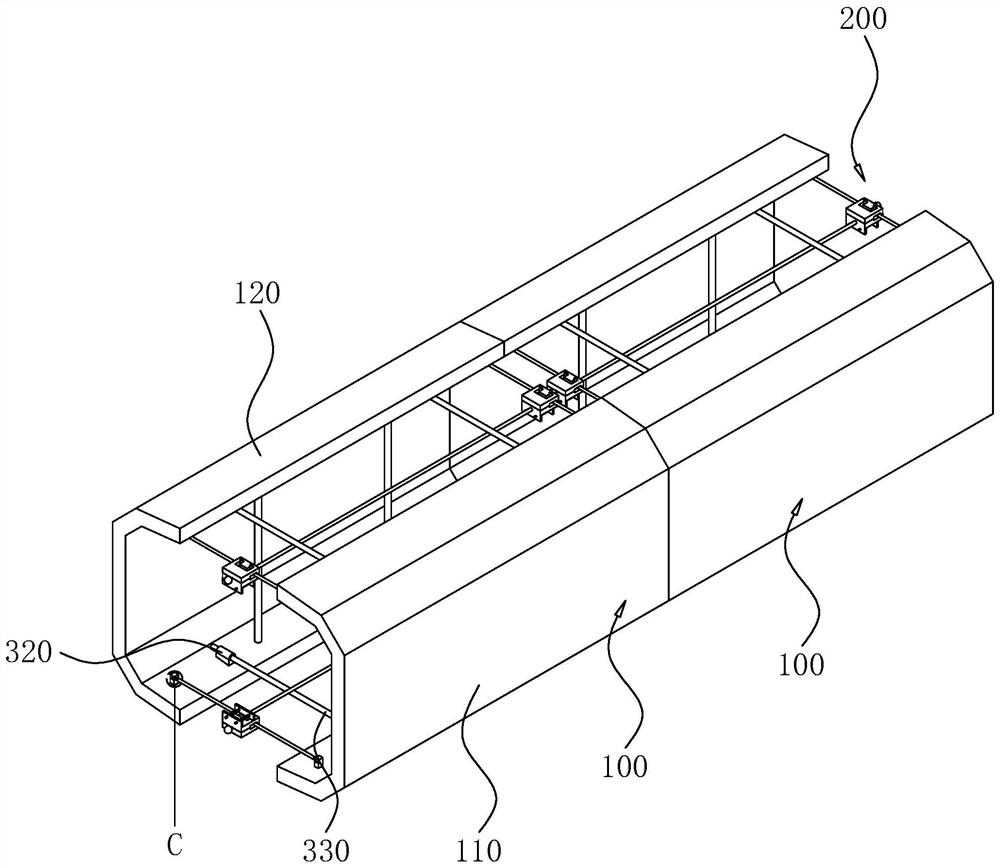

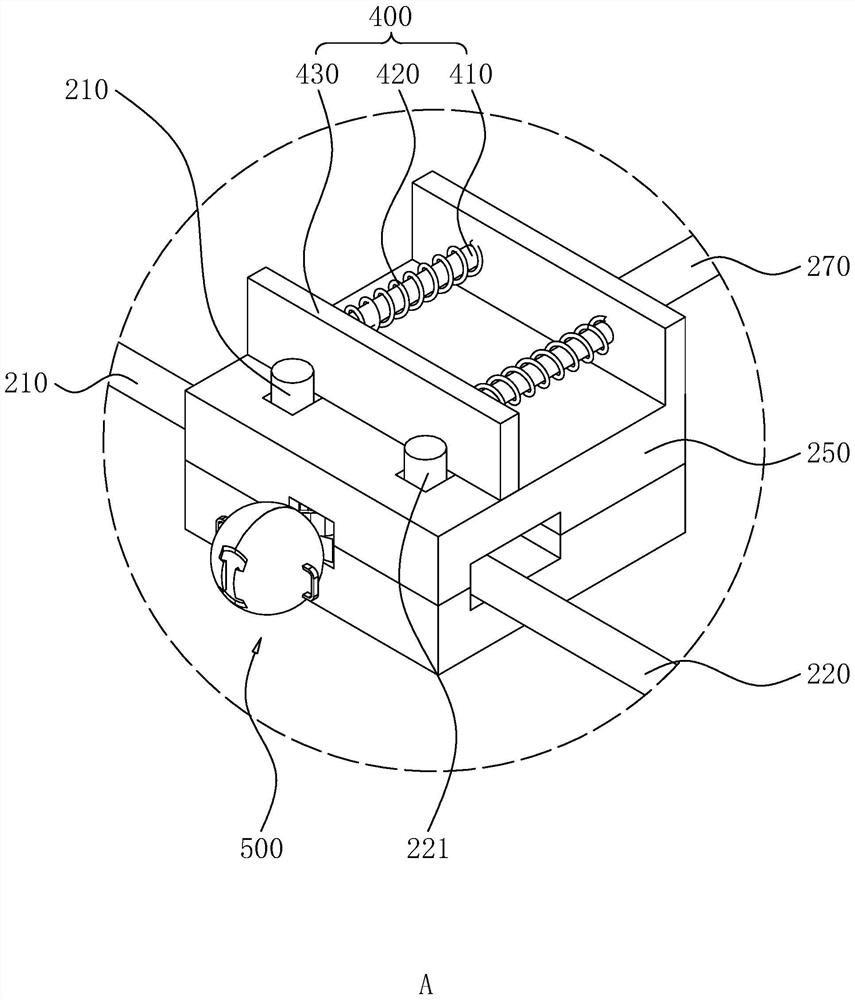

[0040] The embodiment of the present application discloses a hollow slab girder inner mold that is easy to assemble and disassemble. refer to figure 1 and figure 2 , the hollow slab girder inner mold that is easy to disassemble includes a plurality of independent inner mold sections 100, and each independent inner mold section 100 includes a first half mold 110, a second half mold 120 and a mold for connecting the first half mold 110. The locking mechanism 200 with the second mold half 120 . The first mold half 110 and the second mold half 120 are mirror images, and the cross-sections of the first mold half 110 and the second mold half 120 are C-shaped. When using independent inner mold segments 100 to splice into an inner mold, the first half molds 110 on two adjacent inner mold segments 100 abut in the length direction sequentially, and the first half molds 110 on two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com