Low-speed large-torque hydraulic oil cylinder motor for oil pumping unit

A hydraulic cylinder and high-torque technology, applied in the direction of fluid pressure actuators, etc., can solve the problem of low transmission efficiency of the pumping unit drive system, achieve the effect of simple maintenance and improved transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

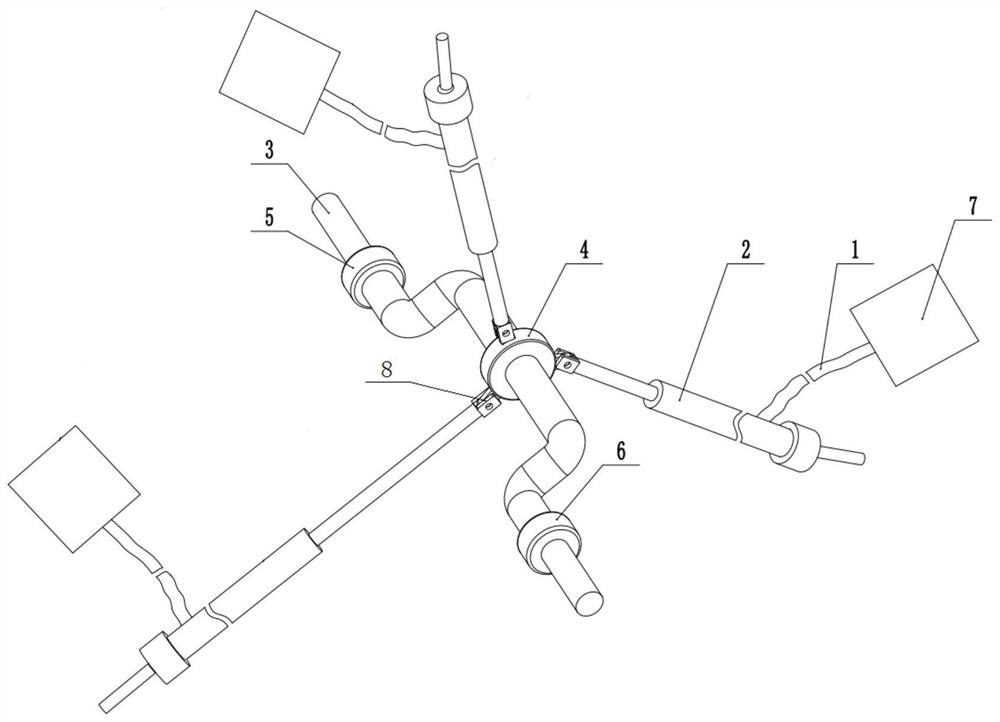

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] like figure 1 As shown, a low-speed high-torque hydraulic cylinder motor for a pumping unit includes an axially horizontal crankshaft 1. The middle section of the crankshaft 1 is a straight shaft. The two ends of the crankshaft 1 are respectively bent downward and then horizontally respectively. This forms the crankshaft structure, and the middle position of the middle section of the crankshaft 1 is coaxially fixed with an articulation disc 4 .

[0014] It also includes three linear push-pull drive mechanisms distributed around the hinged disk, and the three linear push-pull drive mechanisms are evenly distributed in the ring direction. Each linear push-pull drive mechanism includes a hydraulic cylinder 2 respectively, and the hydraulic cylinders 2 are respectively connected to the corresponding hydraulic control system 7 through oil pipes. 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com