Automatic leveling rod horizontal calibration installation device

A technology for leveling and installing devices, which is applied in the field of surveying and mapping, and can solve problems such as blocked sight lines, long distances, and manual support of the level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

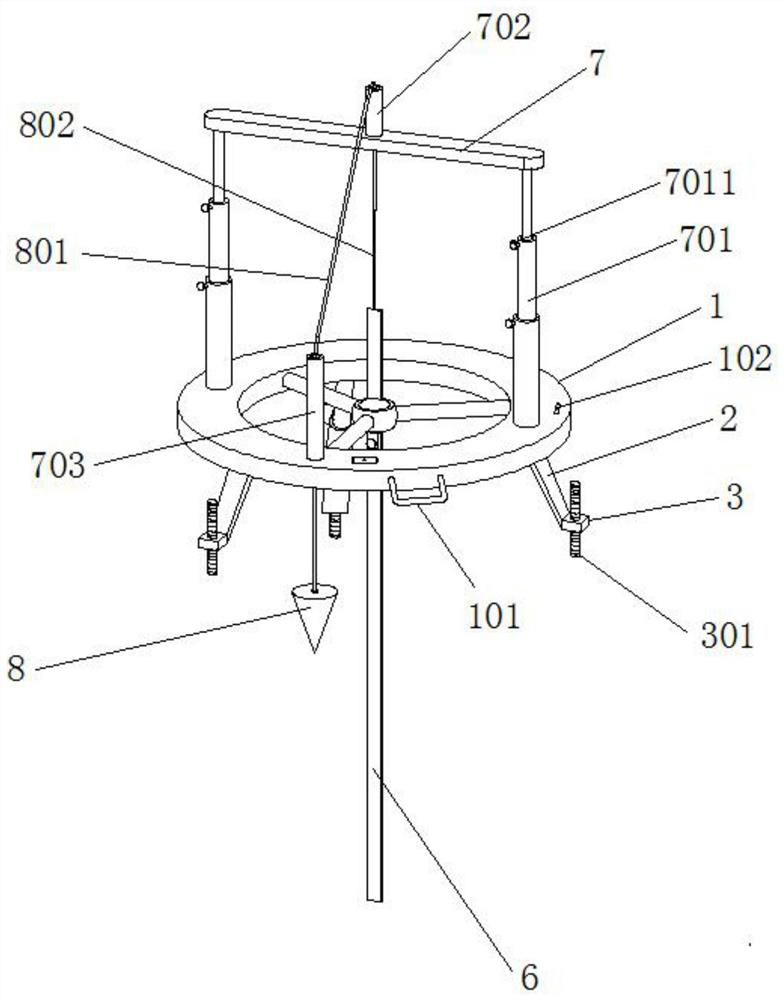

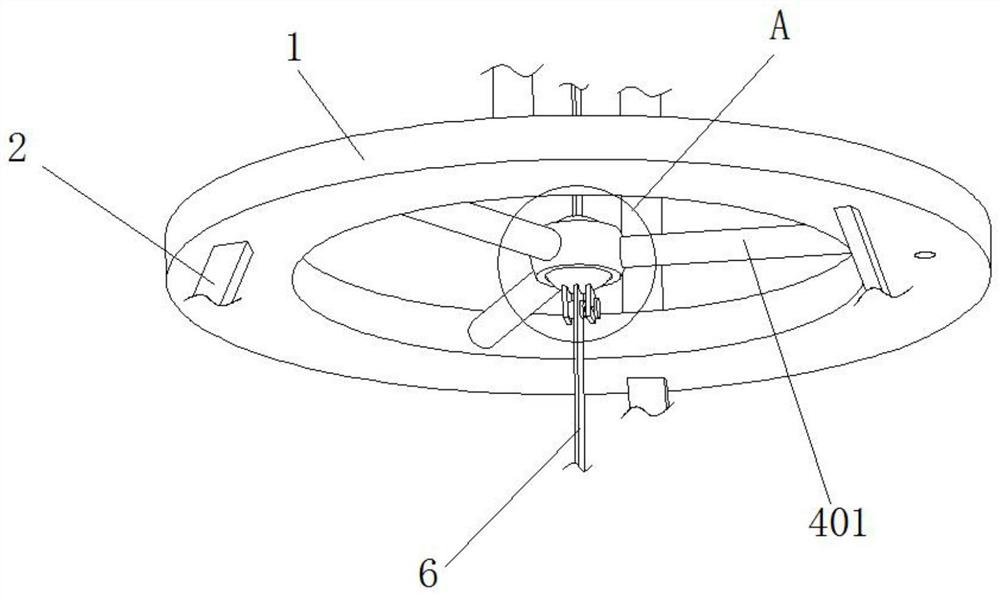

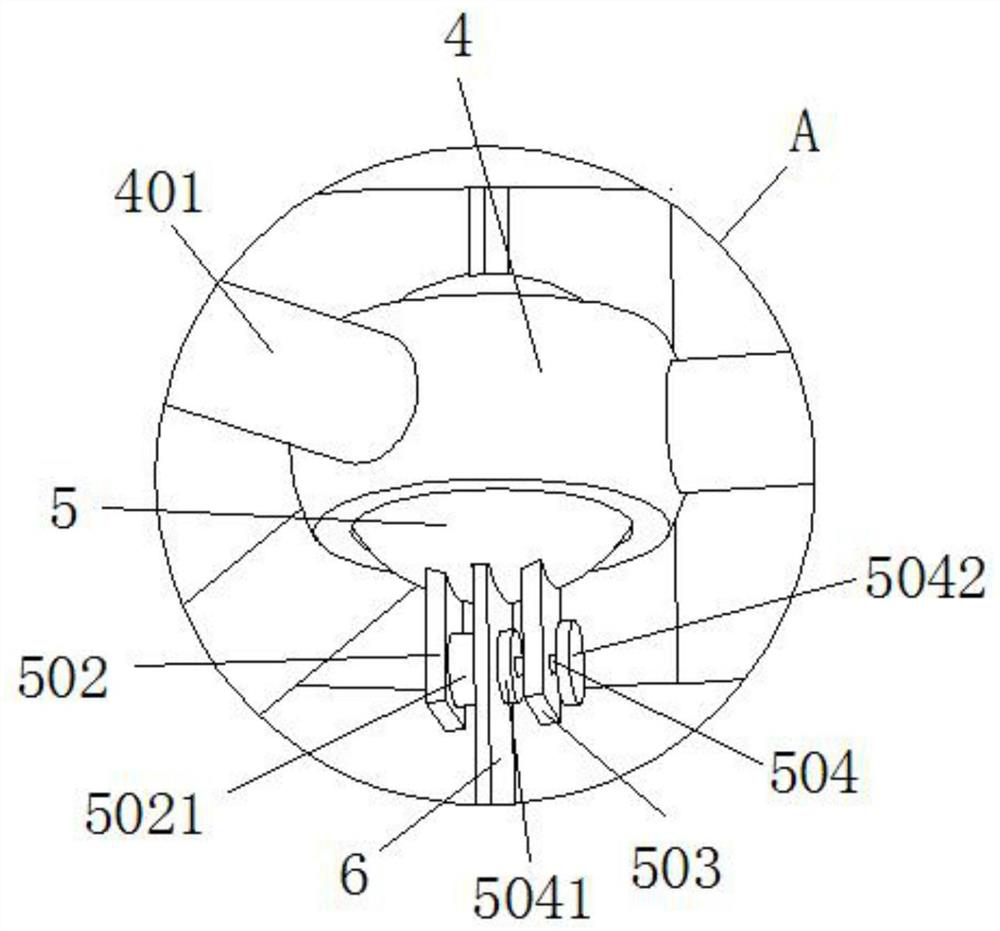

[0030] An embodiment of the present invention provides a leveling rod automatic horizontal calibration installation device, such as Figure 1-4 As shown, it includes supporting annular disk 1, spherical swivel seat 4, rotating sphere 5, leveling rod main body 6, top plate 7 and plumb weight 8. There are three sets of support columns 2 fixedly connected to the bottom of the bottom, and the three sets of support columns 2 are distributed in a circular array along the central axis of the support ring plate 1. The side wall of the spherical swivel seat 4 is fixedly connected with three sets of connecting rods 401, and the connecting rods 401 are far away from the spherical swivel seat. One end of 4 is fixedly connected to the annular inner wall of the supporting annular disk 1, a spherical groove 402 is provided at the center of the spherical swivel seat 4, the rotating sphere 5 is fitted in the spherical groove 402, and the top of the rotating sphere 5 is provided with a ruler gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com