Method and system for removing cumulative errors of product measurement

A technology of accumulative errors and products, which is applied in the field of removing accumulative errors in product measurement, can solve problems such as increased labor intensity and errors, inability to accumulate and display the sum of multiple weighing weights, quantity errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

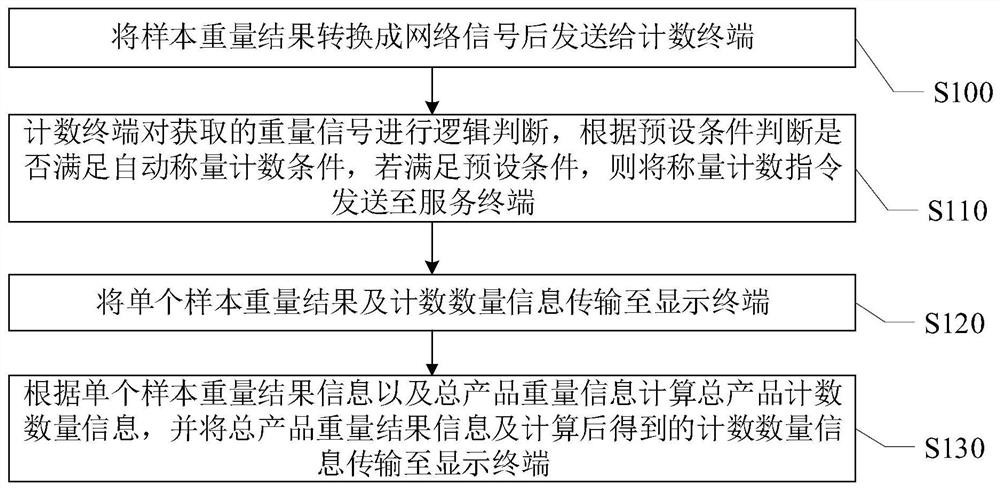

[0030] see figure 1 , figure 1 A schematic diagram of the steps of a method for removing cumulative errors in product metering provided by an embodiment of the present invention is as follows:

[0031] Step S100, converting the sample weight result into a network signal and sending it to the counting terminal;

[0032] Specifically, the sample is one of the multiple items to be weighed of the same type, and the weight of the sample is transmitted by a pressure sensor and converted into a digital signal through AD conversion before it can be processed by the processor, and the processor then sends out a corresponding The network signal to the counting terminal.

[0033] In some implementations, the items to be weighed may include apples and oranges. For example, if there are 100 apples and 200 oranges, the sample of apples is any one of 100 apples, and the sample of oranges is any one of 200 oranges. The weight of the apple sample collected by the pressure sensor is 500g, an...

Embodiment 2

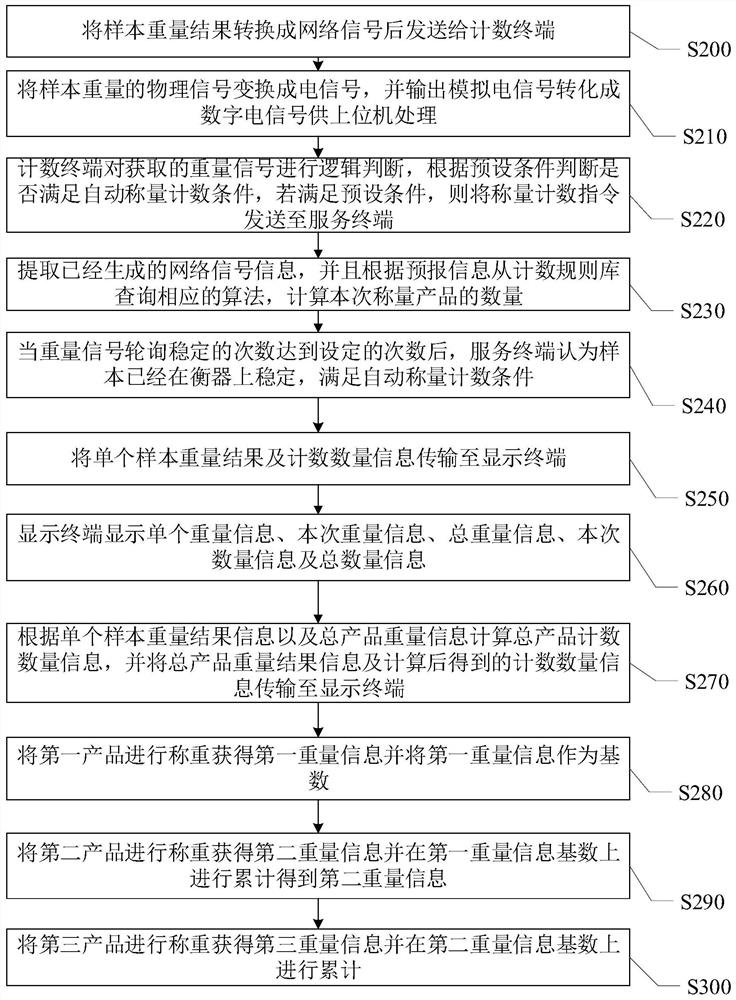

[0043] see figure 2 , figure 2 A schematic diagram of the detailed steps of a method for removing cumulative errors in product metering provided by an embodiment of the present invention is as follows:

[0044] Step S200, converting the sample weight result into a network signal and sending it to the counting terminal;

[0045] Specifically, the sample is one of the multiple items to be weighed of the same type, and the weight of the sample is transmitted by a pressure sensor and converted into a digital signal through AD conversion before it can be processed by the processor, and the processor then sends out a corresponding The network signal to the counting terminal.

[0046] In some implementations, the items to be weighed may include apples and oranges. For example, if there are 100 apples and 200 oranges, the sample of apples is any one of 100 apples, and the sample of oranges is any one of 200 oranges. The weight of the apple sample collected by the pressure sensor ...

Embodiment 3

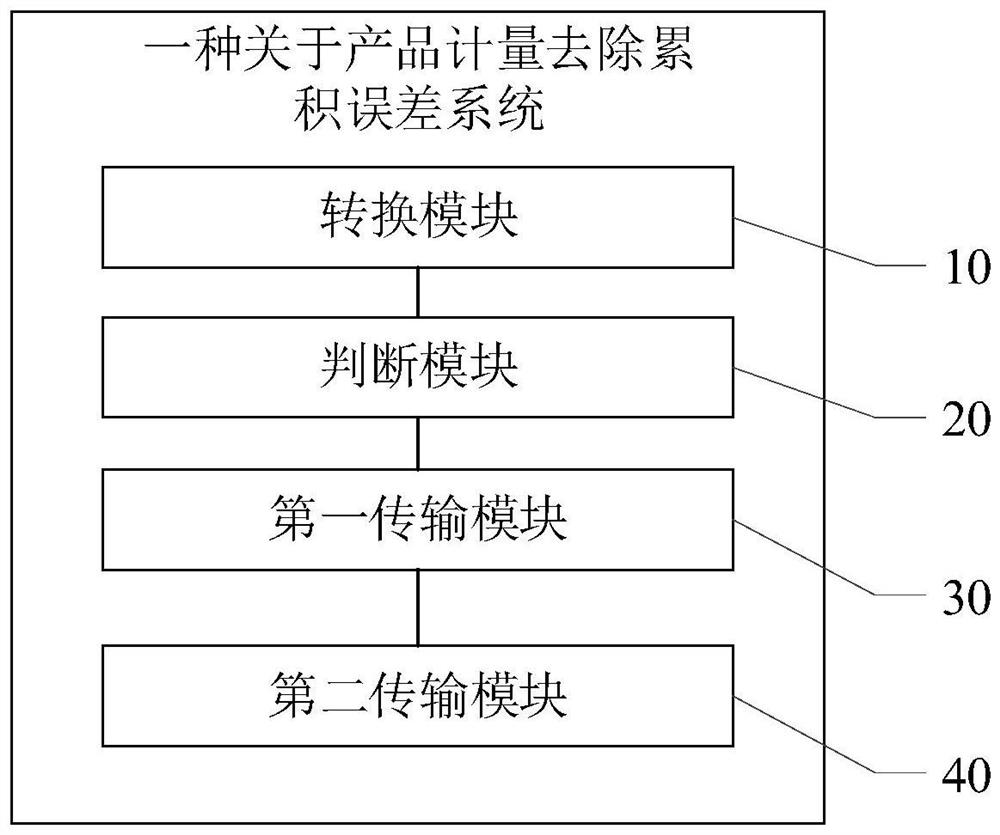

[0075] see image 3 , image 3 A schematic diagram of a system module for removing cumulative errors in product metering provided by an embodiment of the present invention is as follows:

[0076] The conversion module 10 is used to convert the sample weight result into a network signal and send it to the counting terminal;

[0077] The judging module 20 is used for the counting terminal to carry out logical judgment on the weight signal obtained, judge whether to meet the automatic weighing and counting condition according to the preset condition, if the preset condition is met, then send the weighing and counting instruction to the service terminal;

[0078] The first transmission module 30 is used to transmit the single sample weight result and counting quantity information to the display terminal;

[0079] The second transmission module 40 calculates the total product counting quantity information according to the individual sample weight result information and the total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com