A distance-adjustable pin device for connector production and its use method

A technology of pin insertion device and connector, applied in the field of adjustable distance pin insertion device, can solve the problems of waste of manpower, difficulty in guaranteeing product quality and precision, and many subjective factors, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

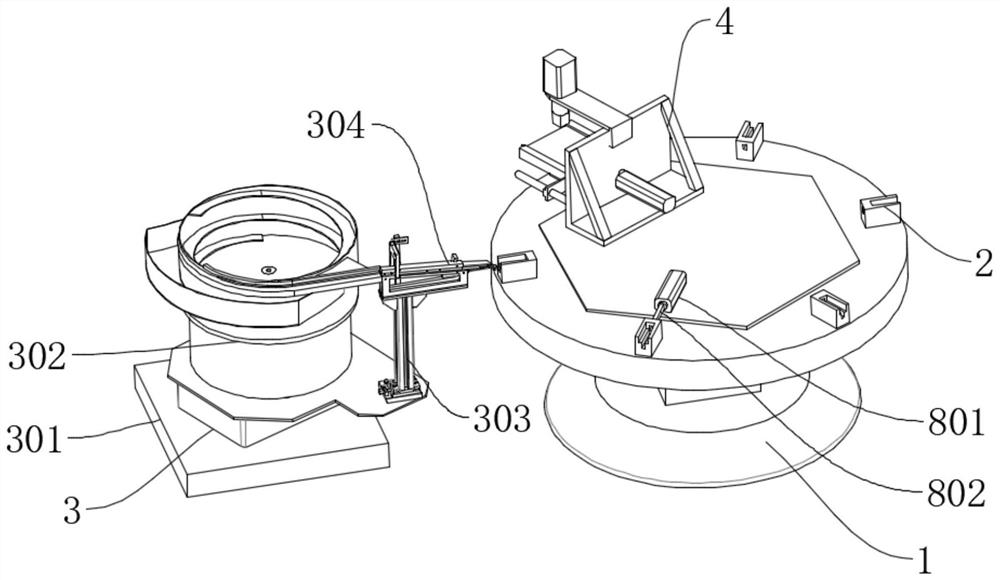

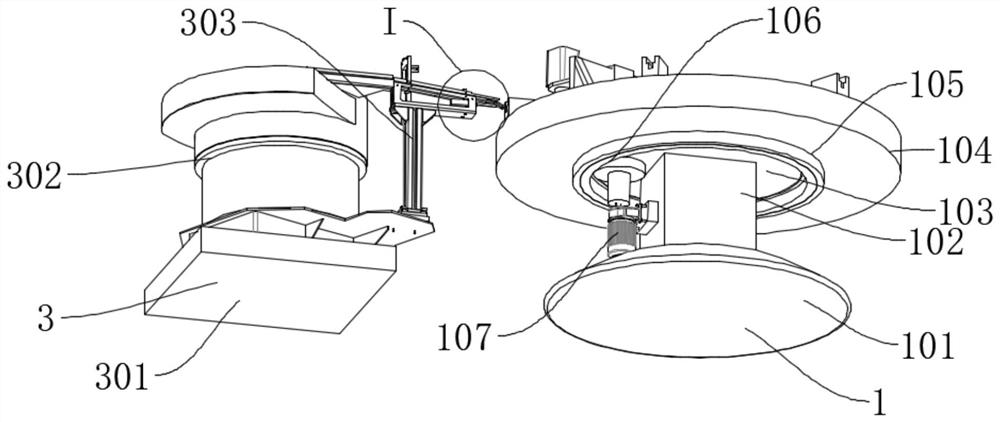

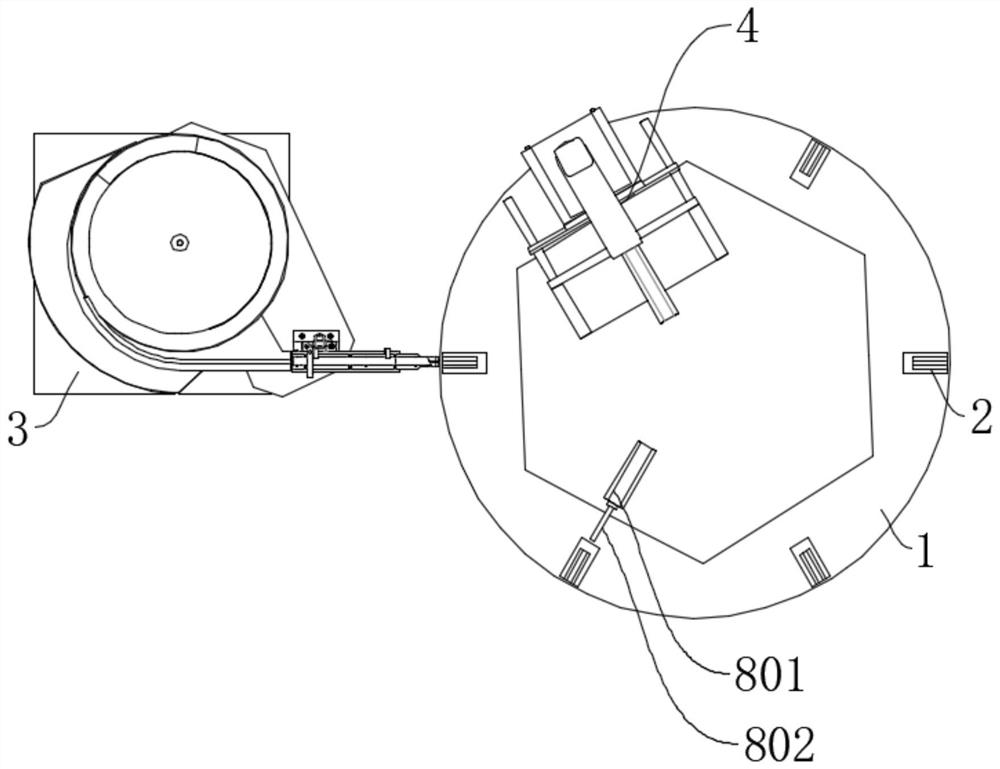

[0040] like Figure 1-7 As shown, a distance-adjustable pin device for connector production includes a feeding mechanism 3, a pin mechanism 4, and a transmission mechanism 1. The transmission mechanism 1 includes a bottom plate 101, a column 102, a top plate 103, a rotating plate 104, Flange 105, internal gear ring 106, transmission motor 107, the center of the top of the bottom plate 101 is connected with a column 102 by bolts, the top of the column 102 is connected with a top plate 103 by bolts, the outer side of the top plate 103 is connected with a rotating plate 104 through bearings, and the bottom of the rotating plate 104 is integrated A flange 105 is formed, and the inner side of the flange 105 is connected with an inner gear ring 106 by screws, and the inner side of the inner gear ring 106 is meshed and connected to the output end of the transmission motor 107, and the transmission motor 107 is connected to the side of the column 102 by bolts, and the top of the rotati...

Embodiment 2

[0042] like Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the positioning assembly includes a card seat 61 and a limit clamp plate 62, the card seat 61 is welded under one end of the two support plates of the placement frame 406, and the inner side of the card seat 61 is clamped The limit clamp 62 can be set in this way so that the limit clamp 62 can be stuck on the inner side of the card seat 61, so that the limit clamp 62 is pushed against the outside of the pin insertion plate 5, and the fixing of the pin insertion plate 5 is realized.

[0043] A method for using a distance-adjustable pin device for connector production, comprising the following steps:

[0044] Step 1: first put the material into the vibrating plate 302 and insert the pin plate 5 with the pins on the inside of the placement frame 406, and then use the positioning component to fix the pin plate 5;

[0045] Step 2: Start the vibrating plate 302 and the first cylinder 305. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com