Gas-liquid combined temperature control device

A technology of temperature control device and gas-liquid combination, which is applied in centrifuges and other directions, can solve problems such as temperature rise and affect the performance of electronic components, and achieve the effects of reducing pressure head, improving heat exchange capacity, and increasing heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

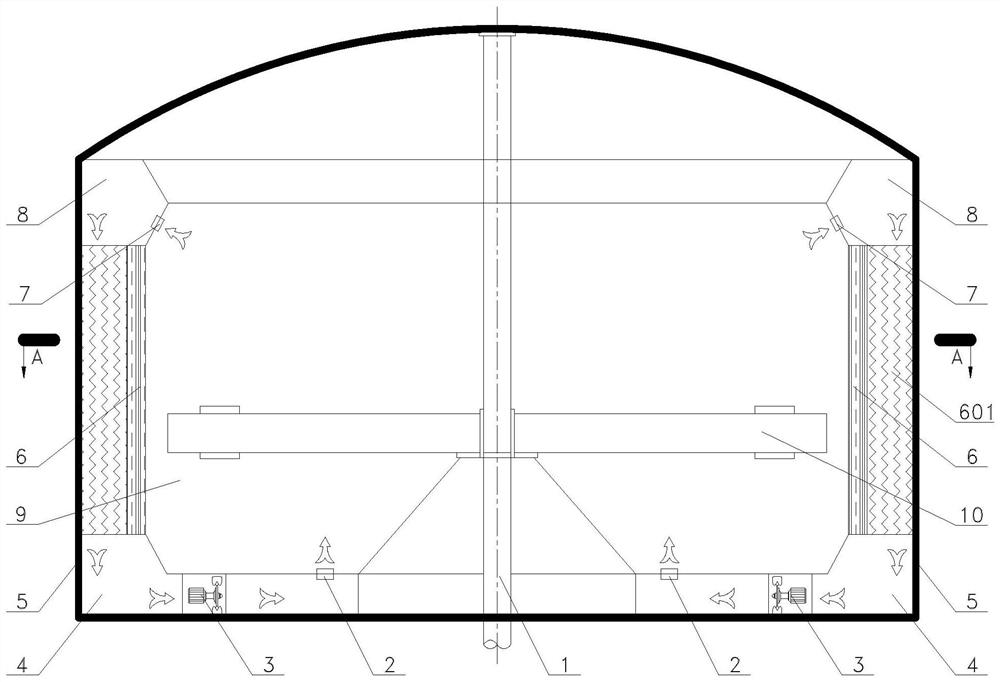

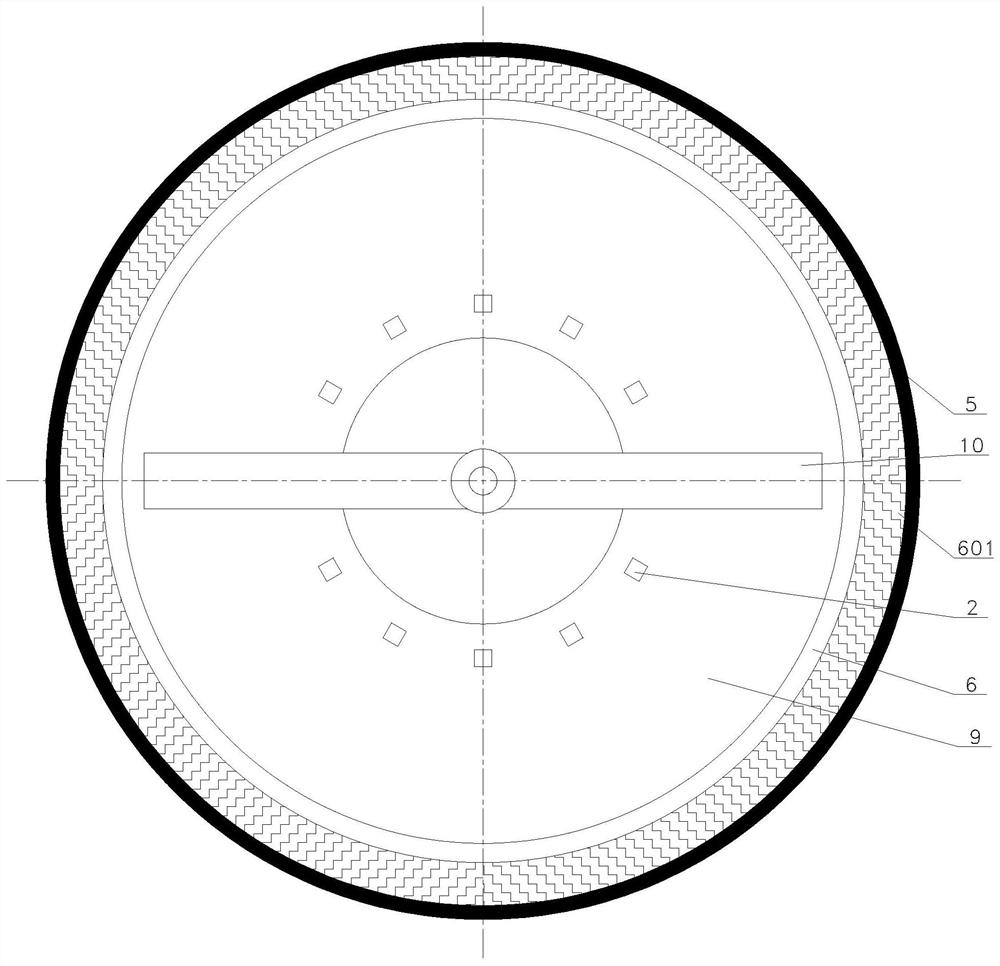

[0015] Such as figure 1 , figure 2 As shown, a gas-liquid combined temperature control device, the gas-liquid combined temperature control device is arranged in the host chamber 9 of the geotechnical centrifuge, and the gas-liquid combined temperature control device includes The air duct 8, the air outlet duct 4 arranged at the bottom of the main engine room 9 of the centrifuge, and the side wall heat exchanger 6 arranged on the inner wall of the main engine room 9, the side wall heat exchanger 6 is provided with heat exchange fins 601, and the air inlet The duct 8 communicates with the end of the air duct 4 close to the inner wall of the main machine room 9 through the heat exchange fins 601 .

[0016] One side of the side wall heat exchanger 6 facing the interior of the main engine chamber 9 is a smooth surface, and the other side of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com