Front auxiliary frame rear mounting seat structure, front auxiliary frame and vehicle

A front subframe and mounting seat technology, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problems of uneven force on the rear mounting seat, unstable connection of parts, affecting the performance of the whole vehicle, etc. The effect of reducing the heat-affected area of the weld, reducing the effect of the joint strength, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

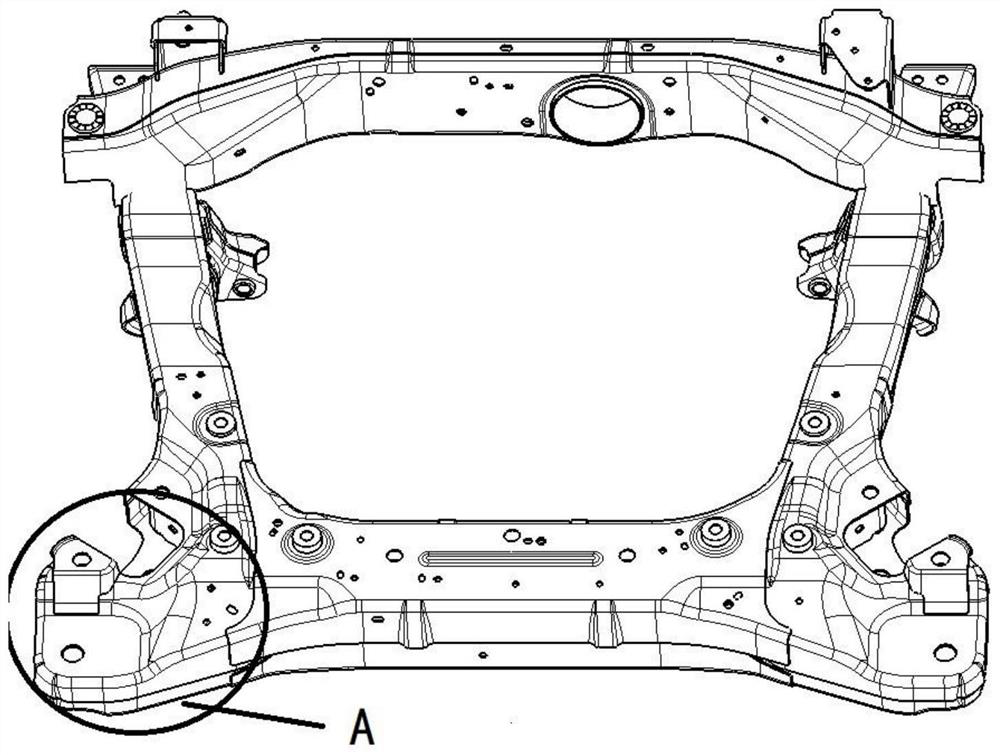

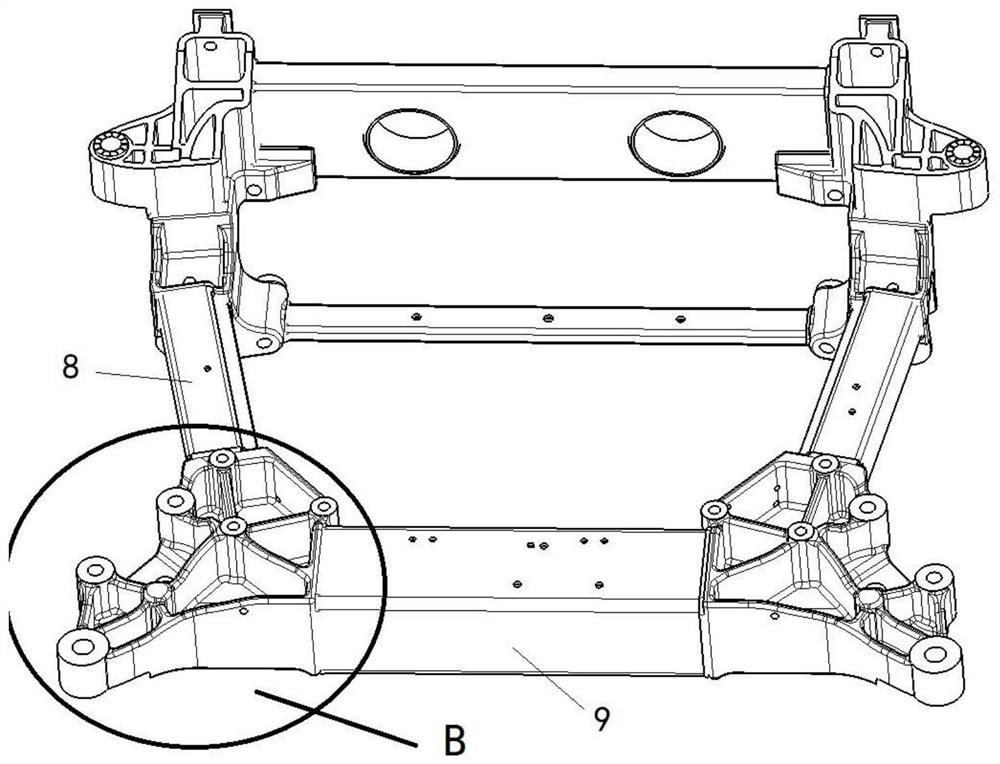

[0031] As a very important structural part in the automobile chassis system, the front sub-frame of the automobile is mainly used to connect the front axle and the body, and to carry and transmit loads. Since there are many parts and structures connected with the front subframe, the design of the front subframe is particularly important. In view of the fact that the existing subframe has many connecting parts and the structure is unstable, an embodiment of this specification provides a rear mounting seat structure for the front subframe, such as image 3 As shown, it is a schematic diagram of the overall structure of the sub-frame provided by the present invention, wherein part B represents the specific position of the rear mounting seat.

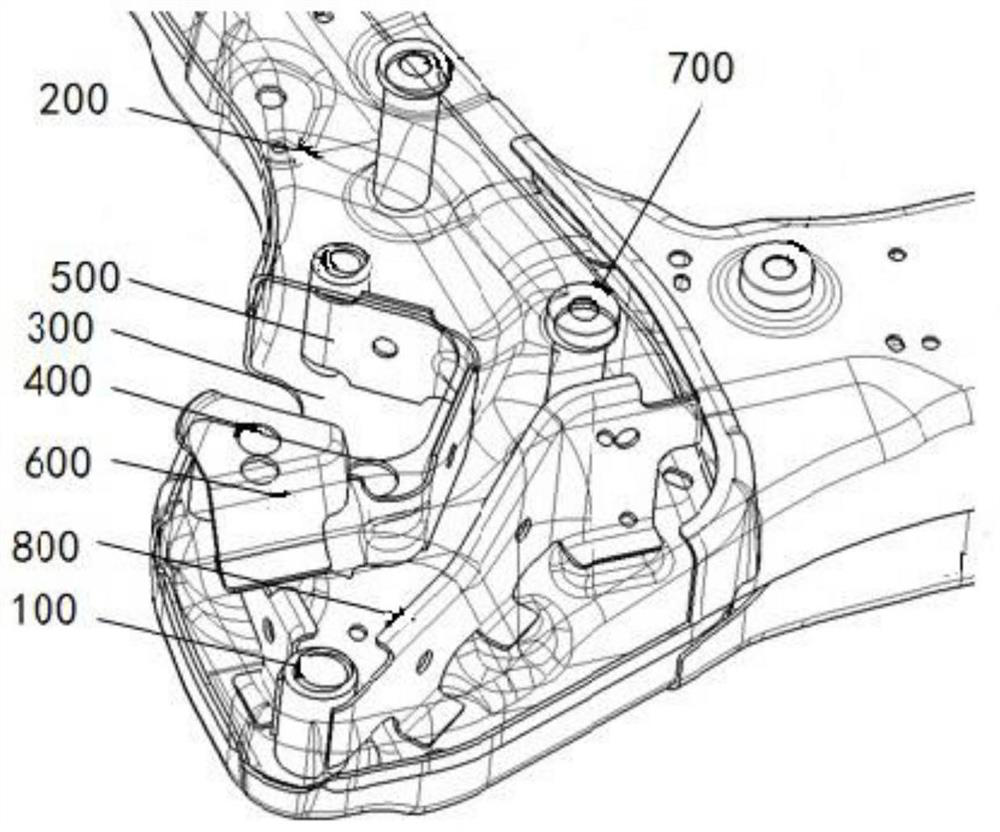

[0032] Specifically, such as Figure 4 Shown is a schematic structural view of the rear mount structure. First, the rear mount structure provided by an embodiment of this specification includes a first connection end 3 and a second connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com