Hydraulic lifting platform with reinforcing and binding functions

A hydraulic lifting platform, hydraulic lifting technology, applied in the direction of lifting devices, lifting equipment safety devices, etc., can solve the problems of low safety performance, no reinforcement and binding function, etc., to ensure freedom, increase safety performance, and increase safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

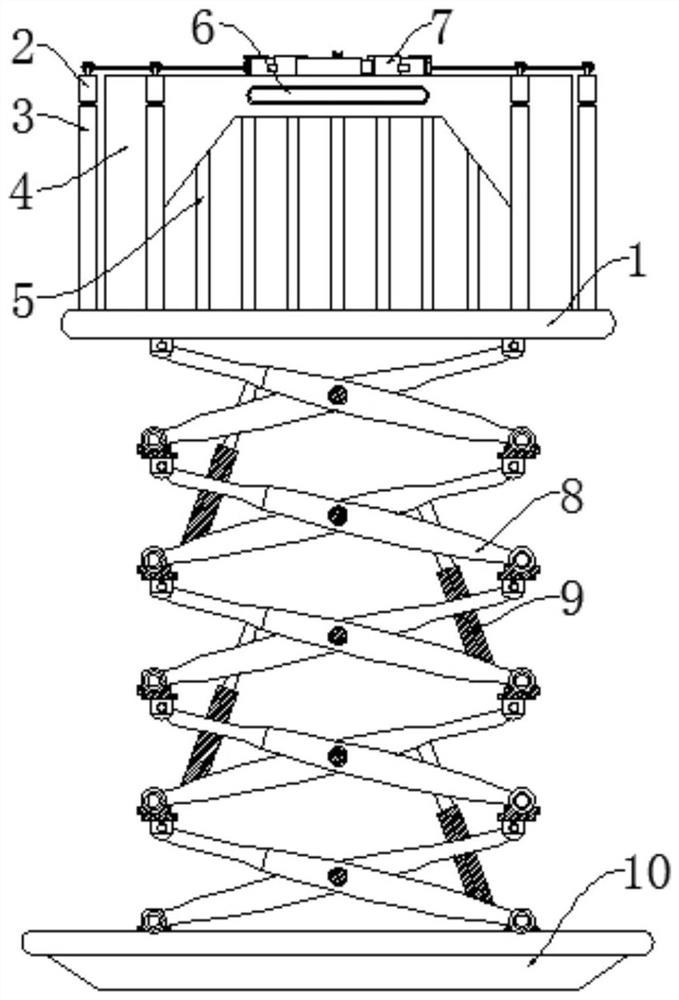

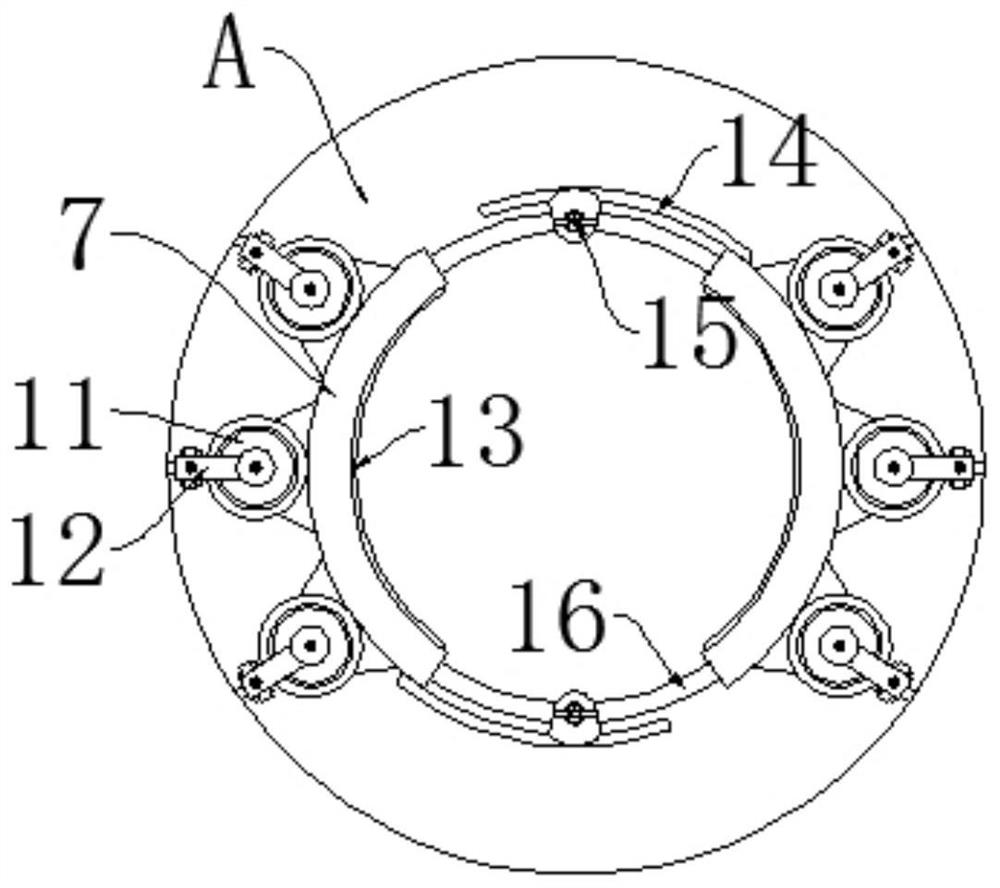

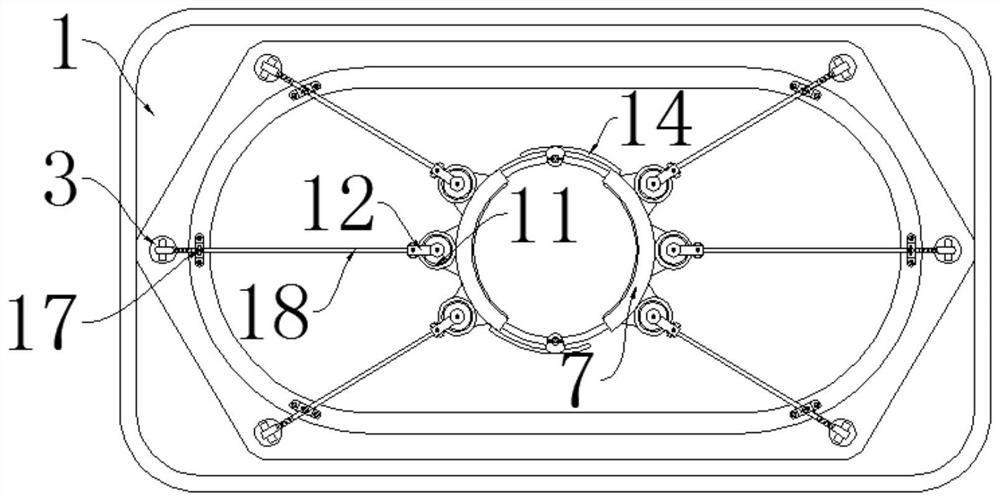

[0019] see Figure 1~3 , in an embodiment of the present invention, a hydraulic lifting platform with a reinforcement binding function, including a hydraulic lifting platform 1 and a lifting frame body 8, a hydraulic lifting platform 1 is installed above the lifting frame body 8, and the hydraulic lifting platform 1 performs high-altitude operations , a guardrail 4 is installed above the hydraulic lifting platform 1, and the guardrail 4 increases the safety of the construction workers. Hollow handles 6 are arranged on both sides of the inside of the guardrail 4. The hollow handle 6 is easy to hold, and the guardrail 4 Both sides of the interior are provided with a plurality of reinforcement bars 5, the reinforcement bars 5 increase the firmness of the guardrail 4, and the reinforcement bars 5 and the guardrail 4 are connected by welding, and the both sides of the guardrail 4 are equipped with fixed rods 3, and the fixed rods 3 Install and fix the rotating sleeve 2, the rotatin...

Embodiment 2

[0022] see Figure 1~3 , in an embodiment of the present invention, a hydraulic lifting platform with a reinforcement binding function, including a hydraulic lifting platform 1 and a lifting frame body 8, a hydraulic lifting platform 1 is installed above the lifting frame body 8, and the hydraulic lifting platform 1 performs high-altitude operations A protective fence 4 is installed above the hydraulic lifting platform 1, and the protective fence 4 increases the safety of the construction personnel. A plurality of reinforcement bars 5 are arranged on both sides of the interior of the protective fence 4, and the reinforcement bars 5 increase the firmness of the protective fence 4. And the reinforcement bar 5 is connected with the guardrail 4 by welding, the both sides of the guardrail 4 are equipped with a fixed rod 3, the fixed rod 3 fixes the rotating sleeve 2, the top of the fixed rod 3 is equipped with a rotating sleeve 2, and the rotating sleeve 2 will adjust The progress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com