Temperature-resistant foam oil-displacing agent, preparation method and application thereof

A foam flooding and temperature-resistant technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as short foam half-life, restrictions on the practical application of foam oil displacement agents, and difficulty in stabilizing foam. Achieve the effects of improving stability, improving oil resistance, and increasing foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

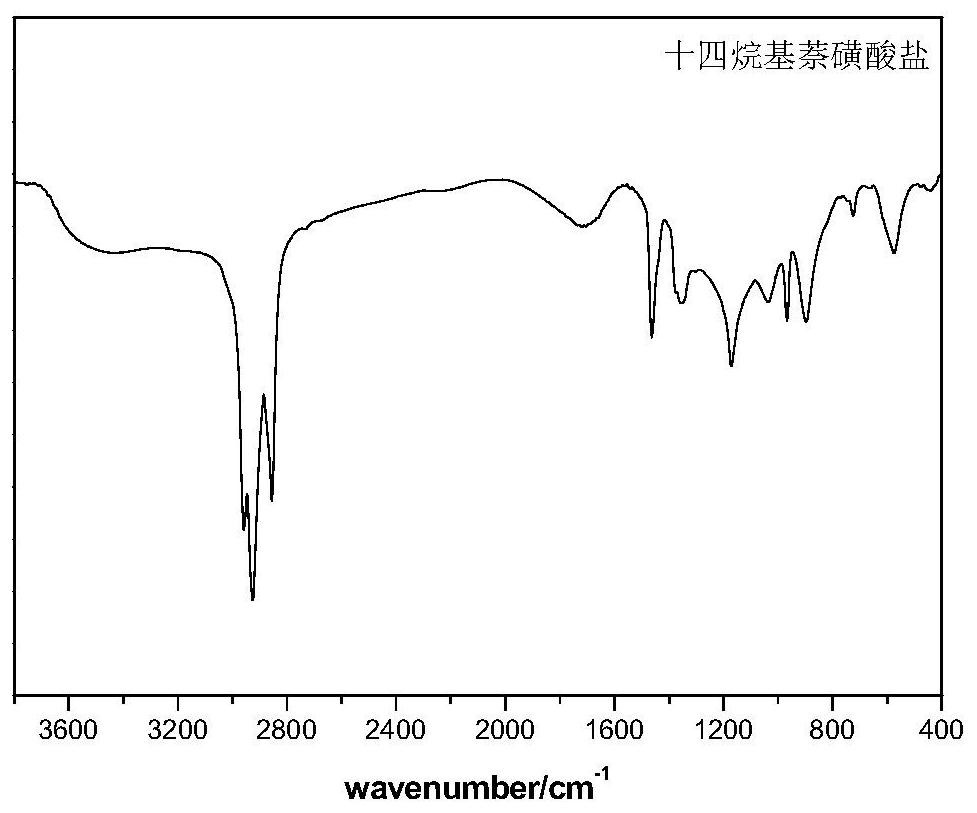

[0054]On the other hand, the embodiments of the present application provide a method for preparing a temperature-resistant foam oil displacing agent, the method is used to prepare any of the above-mentioned foam oil displacing agents, and the method includes: adding olefin into a reactor, and heating to the first A reference temperature of 80-100 ° C, add naphthalene and concentrated sulfuric acid, reflux for 2-6 hours, cool down to the second reference temperature and continue to react for 12-36 hours, add a pH regulator to adjust the pH value to 9-10, and obtain foam after drying Oil displacing agent foaming agent;

[0055] Mix 0.1-0.6% by mass of a foaming agent, 0.01-0.05% by mass of a foam stabilizer and the balance of water to obtain a foam oil-displacing agent.

[0056] Under the oxidation of concentrated sulfuric acid, the foaming agent provided in the examples of the present application undergoes a substitution reaction between the olefin and the hydrogen on the napht...

Embodiment 1

[0077] 60g of 1-tetradecene was added to the reactor, and the temperature was raised to 95°C. Then 50g of naphthalene and 45g of concentrated sulfuric acid were added to the reactor, and the temperature was kept at reflux for 3h, and the temperature was lowered to 25°C. The reaction was continued for 24h, and sodium hydroxide was added to adjust the pH. When the value reaches 10, it is dried with hot air to obtain a foaming agent.

[0078] Take 0.2 g of the above foaming agent, weigh 0.03 g of Welan gum, add 99.77 g of formation water, and mix evenly to obtain a foam oil-displacing agent.

Embodiment 2

[0080] 50g of 1-dodecene was added to the reactor, the temperature was raised to 80°C, then 50g of naphthalene and 40g of concentrated sulfuric acid were added to the reactor, and the temperature was kept for 6h, and the temperature was lowered to 25°C. The reaction was continued for 36h, and sodium hydroxide was added to adjust the pH. When the value reaches 9, it is dried with hot air to obtain a foaming agent.

[0081] Take 0.2 g of the above foaming agent, weigh 0.02 g of welan gum, add 99.78 g of formation water, and mix evenly to obtain a foam oil-displacing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com