Stability testing device and method for motor train unit bogie

A technology for stability testing and bogies, applied in the field of bogies, can solve the problems of complicated operation, low test efficiency, large deviation of test results, etc., and achieve the effects of simple operation, high test efficiency and small deviation of test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

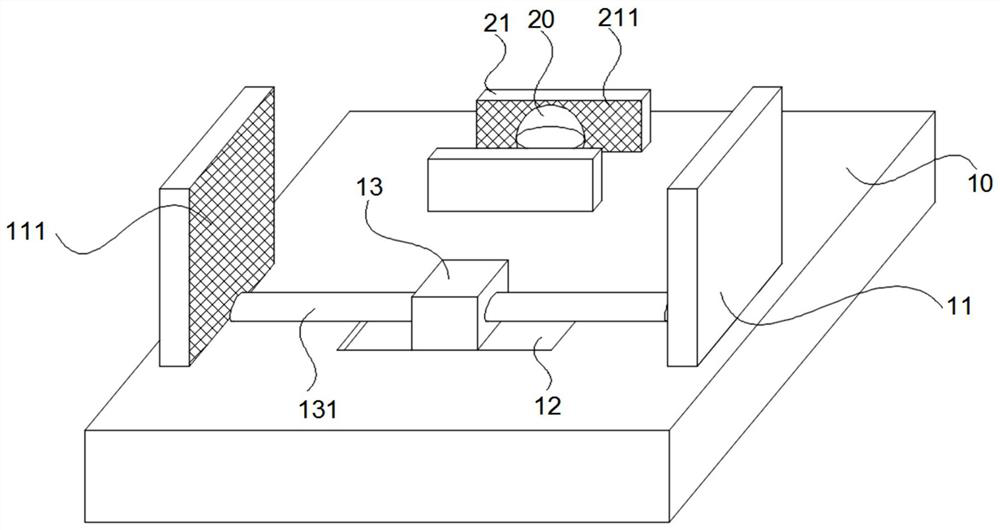

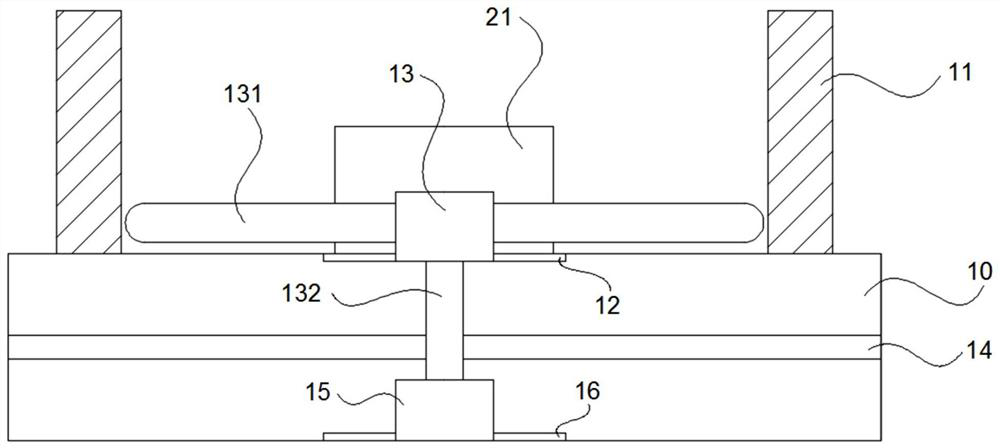

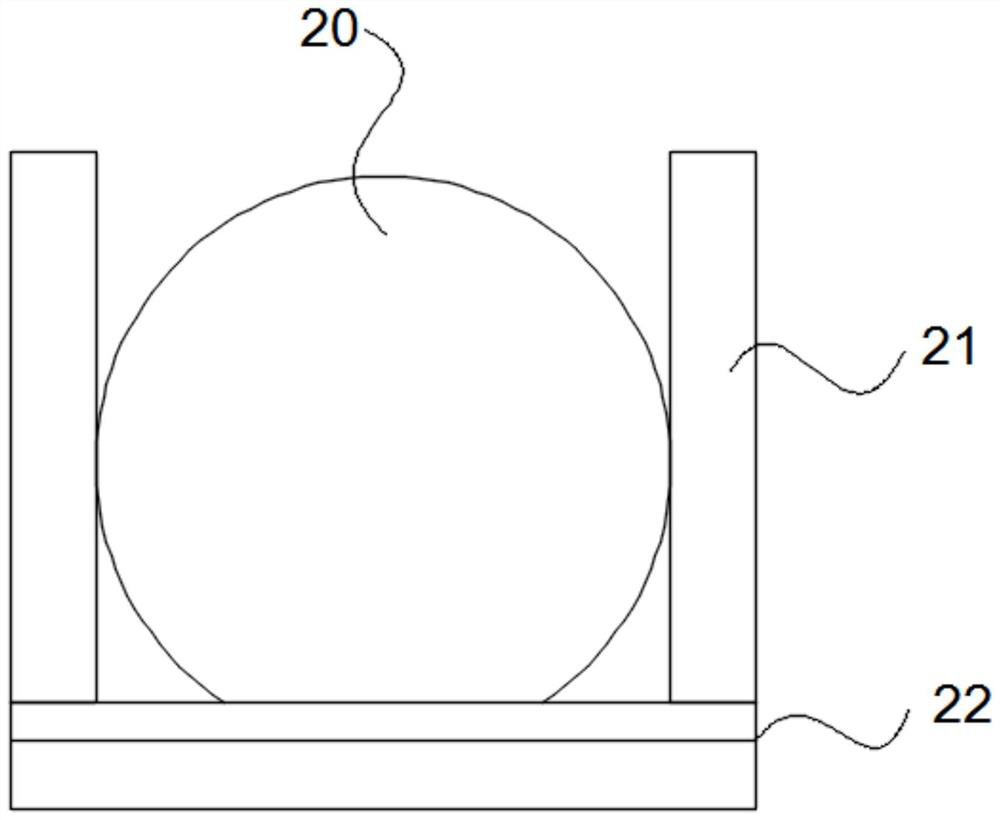

[0034] like Figure 1-Figure 3 As shown, a stability testing device for a bogie of an EMU comprises a base 10, a pair of first collision walls 11 parallel to each other are provided on the top of the base 10, and a first chute is also provided on the top of the base 10 12. The first chute 12 is located between the two first collision walls 11, the straight line where the length direction of the first chute 12 is located is perpendicular to the surface where the first collision wall 11 is located, and the first chute 12 is provided with a first slider 13, the side of the first slider 13 opposite to the two first collision walls 11 is respectively provided with a pressure bar 131, the corresponding pressure of the two first collision walls 11 Ends of the rods 131 are respectively provided with first pressure sensors 111 .

[0035] The working principle of the above-mentioned technical scheme is as follows:

[0036] The EMU bogie test device is placed on the top of different ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com