Concrete setting time test method based on aggregate equal specific surface area substitution principle

A specific surface area and test method technology, applied in the direction of analyzing materials, flow characteristics, measuring devices, etc., can solve problems that affect the accuracy of setting time, unevenness of mortar, difficulty in screening out mortar, etc., to ensure test accuracy, The repeatability test deviation is small, and the effect of reducing the test deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Select the C30 underwater super retarded concrete production formula of a production mixing station of our company. According to the concrete quality per cubic meter, 1034kg of gravel, 719kg of mixed sand mixed with mountain sand and machine-made sand at a ratio of 1:4, 277kg of cement, and Class II pulverized coal 92kg of ash, 92kg of S75 slag powder, 185kg of water, 9.7kg of naphthalene-based water reducer, and 1.32kg of sodium gluconate. Follow the steps below to determine the setting time of concrete:

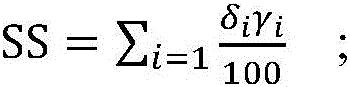

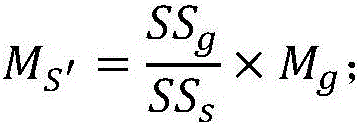

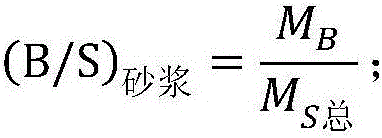

[0040] (1) Gradation of concrete sand and gravel particles actually used in the test project and calculation of the specific surface area SS of the sand and gravel g and SS s ,Methods as below:

[0041] ①Measure the sieve residue on each sieve of concrete sand and gravel according to JGJ 52 of "Sand and Stone Quality and Inspection Method Standard for Ordinary Concrete", accurate to 0.1%;

[0042] The screening test results of gravel and mixed sand used in the C30...

Embodiment 2

[0073] Select C10, C20 and C40 underwater ultra-retarded concrete production formulas from three production mixing stations of our company, and follow the steps of this method to measure the setting time of concrete. The determined mortar mix ratio is shown in Table 3, and the setting time test results are shown in Table 4.

[0074] Table 2 concrete mix ratio

[0075]

[0076] Table 3 Mortar mix ratio calculated and determined by using aggregate equal specific surface area substitution principle

[0077]

[0078] Table 4 coagulation time test results

[0079]

[0080] By adopting the method of the present invention to carry out the example verification of the production formula of C10, C20 and C40 underwater super-retarded concrete produced by our company, the test result of the method of the present invention is compared with the test result of the national standard method, and the deviation of the setting time of the two is less than 5 %, good consistency.

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com