Surgical instrument clamping force sensing method based on deep learning

A surgical instrument and deep learning technology, applied in the field of medical robots, can solve the problems of inability to accurately obtain the clamping force of surgical instruments and low precision, and achieve the effect of improving perception accuracy and improving acquisition accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

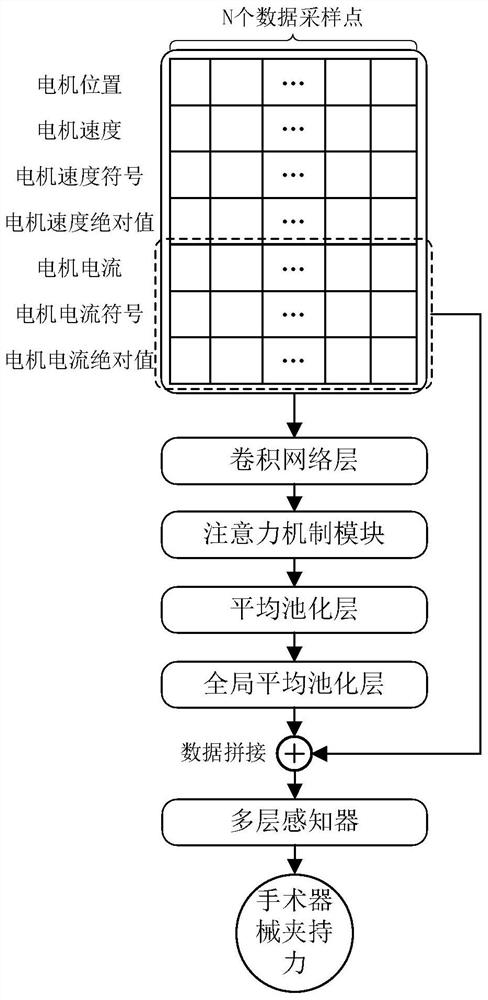

[0018] Specific implementation mode one: combine figure 1 Describe this embodiment, the deep learning-based surgical instrument clamping force perception method described in this embodiment, its specific method is as follows:

[0019] Step 1. Use the motor position θ and motor speed collected from the minimally invasive surgical robot system motor speed symbol Absolute value of motor speed Motor current I, motor current symbol sgn(I), motor current absolute value abs(I t ) to construct the input data matrix M;

[0020] Step 2. Input the data input matrix M into the convolutional network layer, input the output result into the attention mechanism module, further input the output result into the average pooling layer, and then input the output result into the global average pooling layer;

[0021] Step 3. Data splicing of the motor current, motor current sign, and absolute value of the motor current in the input data matrix M and the output result of the global average po...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is a further limitation of the clamping force sensing method described in the first specific embodiment. In the deep learning-based surgical instrument clamping force sensing method described in this embodiment, in the first step data matrix Among them, sgn( ) means to take symbolic operation, abs( ) means to take absolute value calculation, the subscript t means the data of the current sampling period, and t-1 means the data of the previous sampling period;

[0025] In this specific embodiment, using the motor position θ, the motor speed motor speed symbol Absolute value of motor speed Motor current I, motor current symbol sgn(I), motor current absolute value abs(I t ) constructs a data matrix M to provide a rich and accurate data source for clamping force perception, thereby solving the shortcomings of high cost and poor accuracy of the existing minimally invasive ...

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 Describe this embodiment. This embodiment is a further limitation of the clamping force sensing method described in the first specific embodiment. In the deep learning-based surgical instrument clamping force sensing method described in this embodiment, in the second step The convolution kernel size of the convolutional network layer is 3×3, the number of convolution kernels is 128, the convolution step is 1, and the activation function is ReLu;

[0027] In this specific embodiment, the size of the convolution kernel of the convolutional network layer in step 2 is 3×3, the number of convolution kernels is 128, the convolution step is 1, and the activation function is ReLu, which can be implemented in minimally invasive surgery. Accurately obtain the holding force of surgical instruments in the robot system to improve the accuracy of acquisition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com