Lamination layer deviation control method for multilayer FPC board

A control method and board stacking technology, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve problems such as layer deviation, large compression expansion and contraction deviation, etc., to achieve easy bending, quality and efficiency assurance, avoid The effect of product deformation layer deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

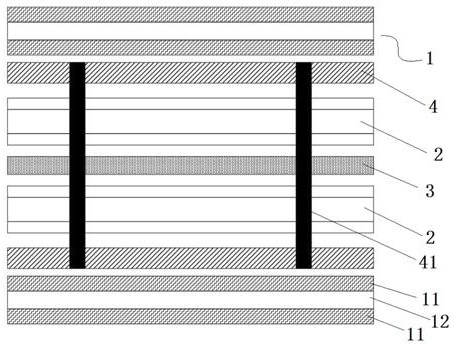

[0031] A method for controlling lamination bias of a multilayer FPC board, characterized in that it comprises the following steps:

[0032] S1. FPC layer production;

[0033] S2. Glue-coated PI layer production;

[0034] S3. Fabrication of supporting slabs;

[0035] S4. The production of the main card pressing laminated board: when pressing the laminated board, riveting the upper and lower sides of the support board and the stacked FPC layer together to carry out the pressing of the boards for hardness support;

[0036] S5. Remove the support plate after pressing: After pressing the multi-layer FPC board, drill the rivets at the riveting position of the board edge with a drill nozzle, remove the support plate, and take out the normal multi-layer FPC board. The post-process production can be carried out in the normal way.

[0037] In the present invention, the material characteristics of the FPC board are aimed at: light weight, thinner, easy to bend, extruded by high temper...

Embodiment 2

[0047] A method for controlling lamination bias of a multilayer FPC board, characterized in that it comprises the following steps:

[0048] S1. FPC layer production;

[0049] S2. Glue-coated PI layer production;

[0050] S3. Fabrication of supporting slabs;

[0051] S4. The production of the main card pressing laminated board: when pressing the laminated board, riveting the upper and lower sides of the support board and the stacked FPC layer together to carry out the pressing of the boards for hardness support;

[0052] S5. Remove the support plate after pressing: After pressing the multi-layer FPC board, drill the rivets at the riveting position of the board edge with a drill nozzle, remove the support plate, and take out the normal multi-layer FPC board. The post-process production can be carried out in the normal way.

[0053] In the present invention, the material characteristics of the FPC board are aimed at: light weight, thinner, easy to bend, extruded by high temper...

Embodiment 3

[0063] A method for controlling lamination bias of a multilayer FPC board, characterized in that it comprises the following steps:

[0064] S1. FPC layer production;

[0065] S2. Glue-coated PI layer production;

[0066] S3. Fabrication of supporting slabs;

[0067] S4. The production of the main card pressing laminated board: when pressing the laminated board, riveting the upper and lower sides of the support board and the stacked FPC layer together to carry out the pressing of the boards for hardness support;

[0068] S5. Remove the support plate after pressing: After pressing the multi-layer FPC board, drill the rivets at the riveting position of the board edge with a drill nozzle, remove the support plate, and take out the normal multi-layer FPC board. The post-process production can be carried out in the normal way.

[0069] In the present invention, the material characteristics of the FPC board are aimed at: light weight, thinner, easy to bend, extruded by high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com