Method for stabilizing size of circuit board with core boards of different thicknesses

A dimensionally stable, circuit board technology, used in printed circuits, multilayer circuit manufacturing, printed circuit manufacturing, etc., to achieve the effect of improving production yield, solving layer deviation problems, and improving production capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0021] figure 1 and figure 2 The difference in dimensional change of the two structures in the production will be completely different. Since the thickness of the core plate of the normal structure is the same, it is only necessary to consider the impact of the remaining copper on the core plate to correct the size. For special structures, it is necessary to consider not only the effect of plate thickness on dimensional changes, but also the stress of other layers and the force difference of the thick core plate. However, there is no solution for special structures in the prior art.

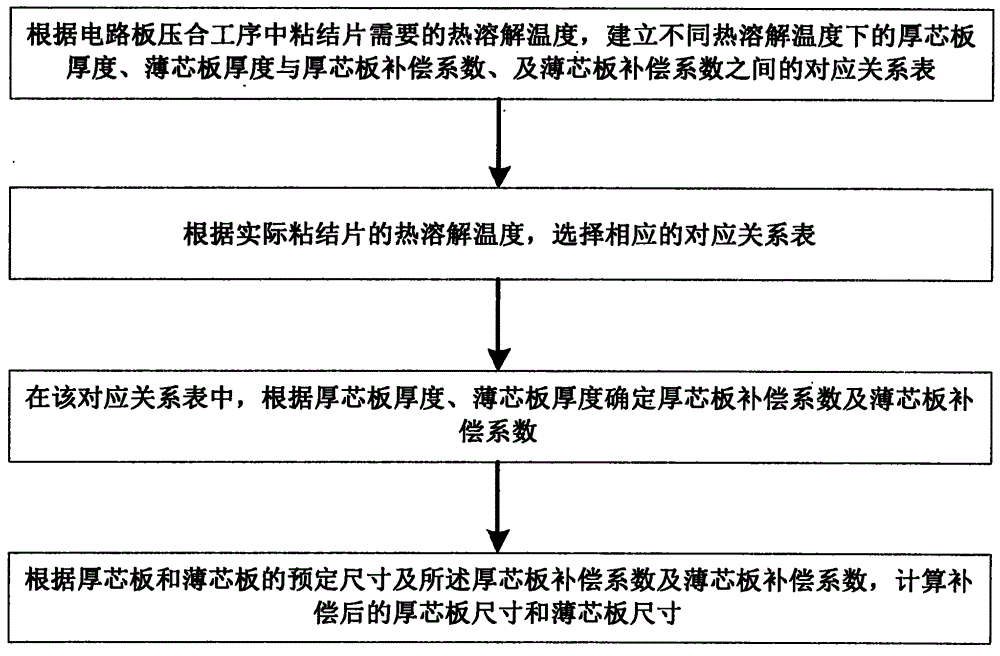

[0022] Please refer to image 3 , the invention provides a method for stabilizing the dimensions of circuit boards with core boards of different thicknesses, compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com