Quick thawing device used for food processing

A food processing and fast technology, applied in the field of food processing, can solve the problems of roasting in some parts of the food, unable to achieve the freshness of the food, troublesome food thawing, etc., and achieve the effect of improving the thawing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

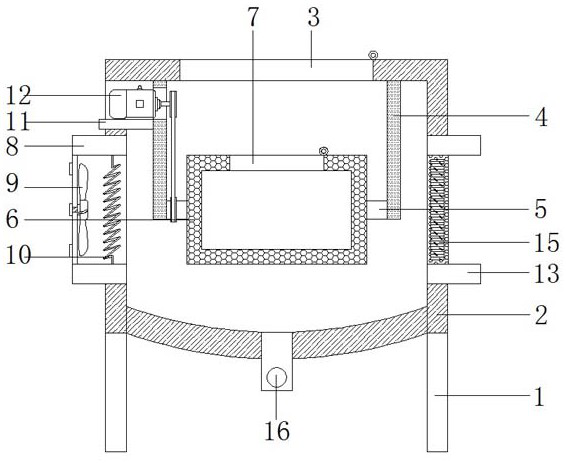

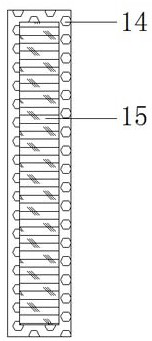

[0019] Embodiment 1, with reference to Figure 1-2 , a fast thawing device for food processing, comprising a housing 2, support legs 1 are welded on the outer walls of the four corners of the bottom of the housing 2, and anti-skid mats are bonded on the outer walls of the bottom ends of the four support legs 1, so There is an opening on the outer wall at the center of the top of the housing 2, and a top cover 3 is hinged in the opening, and fixing plates 4 are welded on the outer walls at both ends of the top of the housing 2, and the bottoms on the opposite sides of the two fixing plates 4 Both end outer walls are connected with rotating shafts 5 through bearings, and grid tubes 6 are welded on the outer walls of the opposite sides of the two rotating shafts 5. There are installation ports on the top outer walls of the grid tubes 6, and the inner walls of the installation ports are A cylinder cover 7 is hinged, a mounting pipe 8 is sleeved on the inner wall of one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com