Method for preparing agar with high-temperature and low-concentration alkali

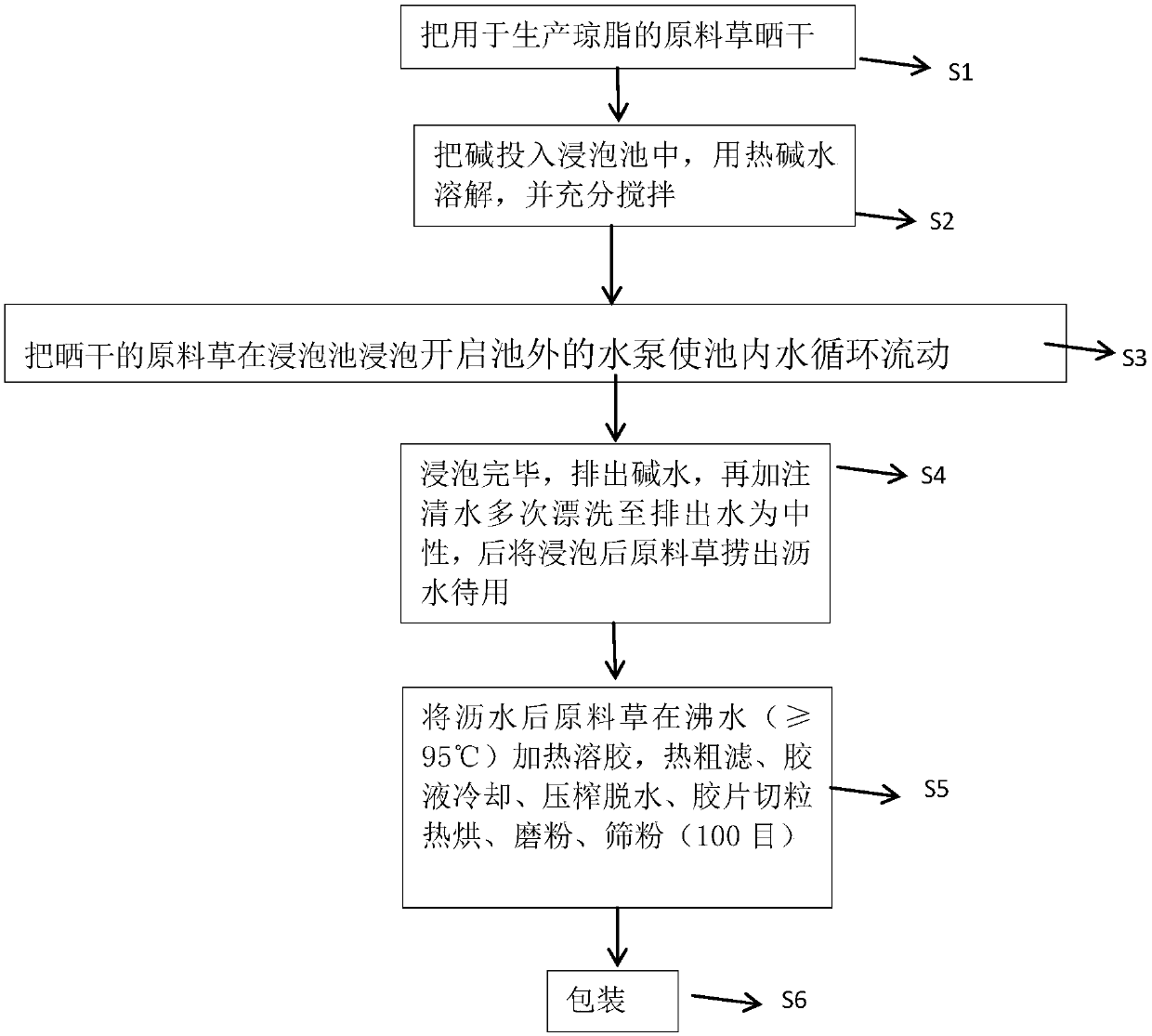

A low-concentration, production method technology, applied in the biological field, can solve the problems of poor hot water circulation, inability to carry out production, and reduced productivity, and achieve the effects of reducing the difficulty of sewage treatment, shortening the production cycle, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0026] (Specific example:) Fill 8 tons of clear water into a immersion tank, turn on steam heating, put in 800KG sodium hydroxide, 40KG sodium carbonate and 8.4KG disodium hydrogen phosphate,,, and start the mixer at the same time to stir to dissolve the input materials, take Divide 6 tons of Gracilaria into 12 bundles and put them into the soaking pool, turn on the hot water circulation pump, adjust the temperature of the lye in the pool to 85°C±2°C, record the start time when the water temperature reaches 85°C, and keep soaking for 100 hours under the condition of hot water circulation. After 10 minutes, stop heating, drain the alkaline water and fill it with clean water. When the clean water is full, it overflows out of the pool. The clean water maintains a flow rate of 6 tons per hour until the pH value of the discharged water is between 6.8 and 8.0, and then the raw materials can be taken out and drained. Sent to glue boiling, hot coarse filtration, glue cooling, pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com