Multi-head laser printing equipment for shoes

A laser printing and multi-head technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of occupying production materials, high scrap rate, graphic misalignment, etc., to meet production needs, good printing effect and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

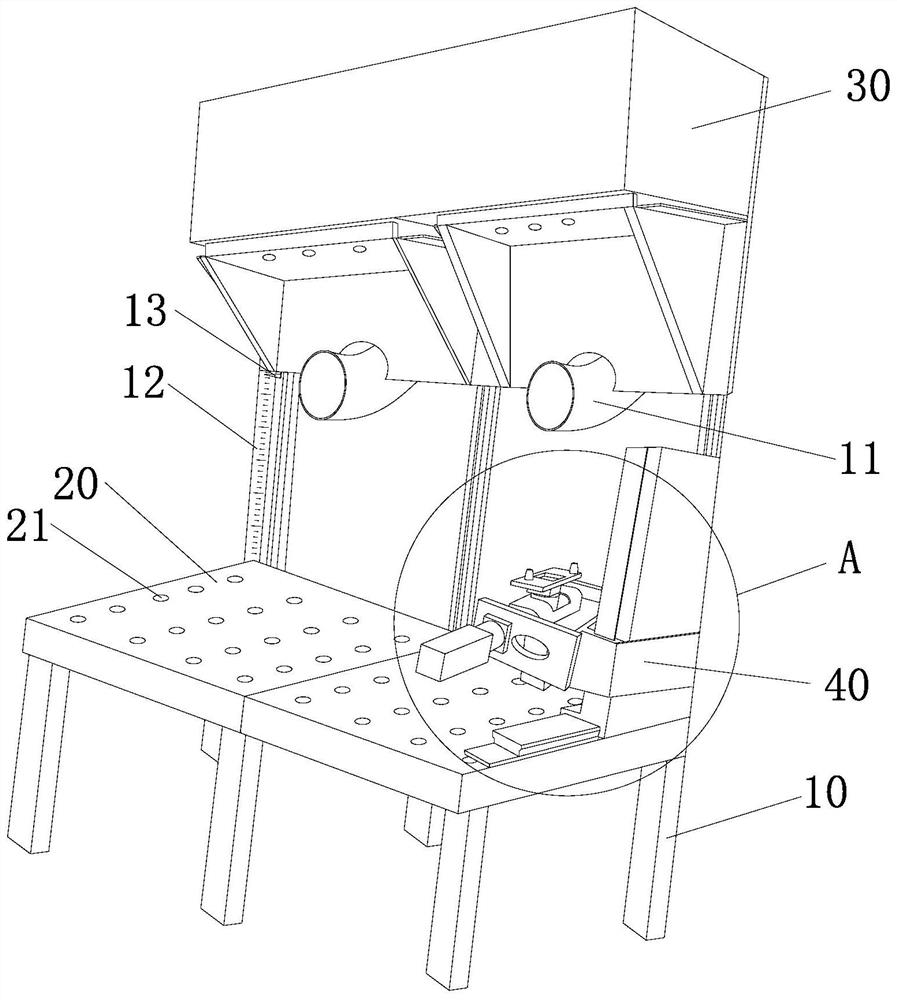

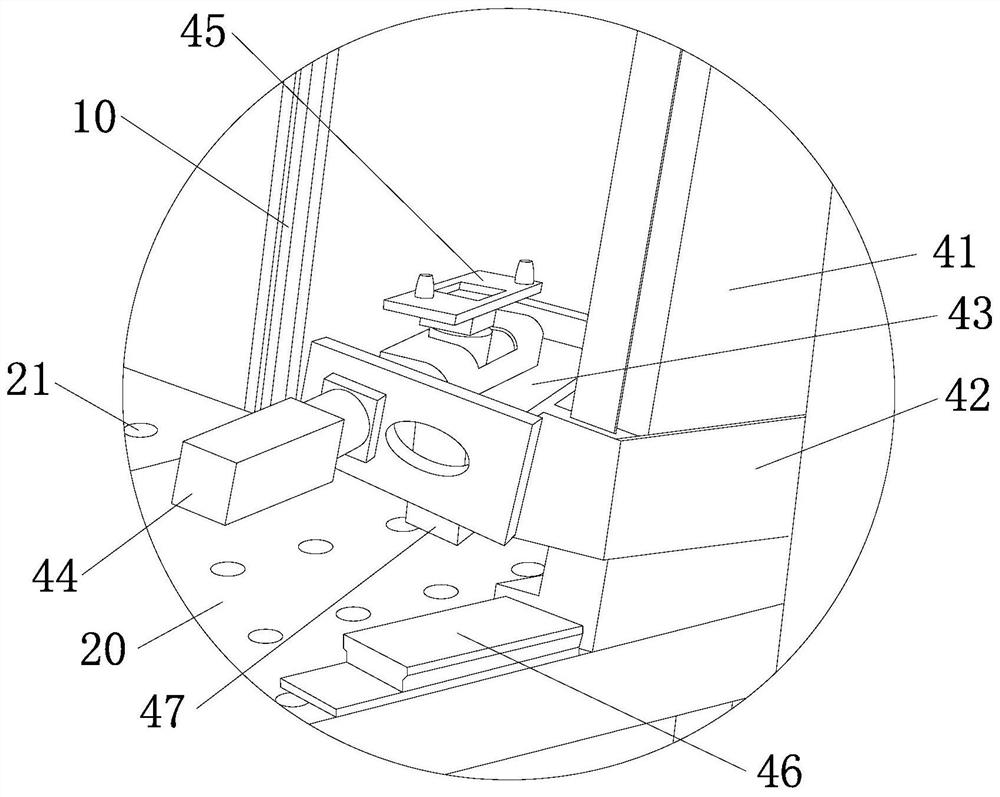

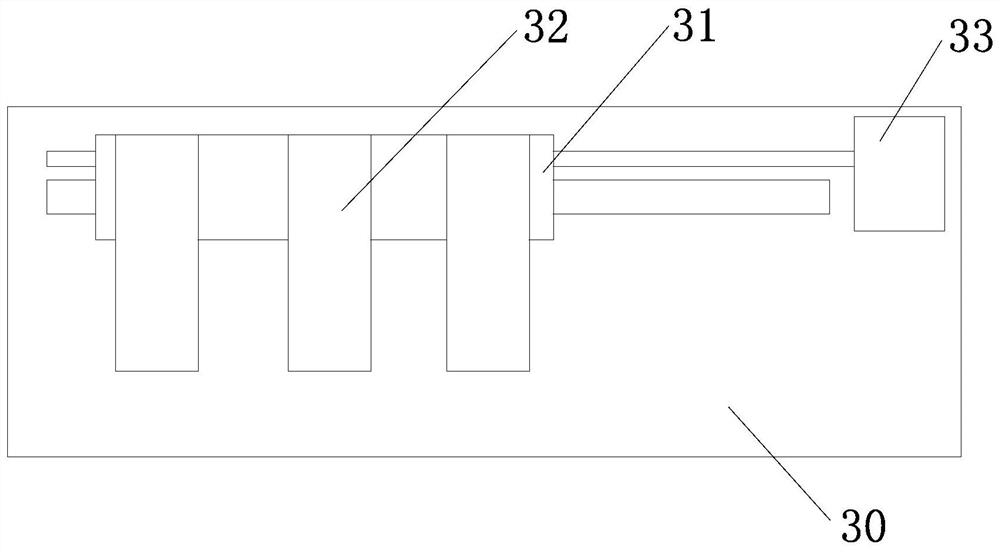

[0035] Such as Figure 1-Figure 3 As shown, the present embodiment provides a multi-head laser printing device for shoes, including a frame 10, a workbench 20 arranged horizontally on the frame 10, vertically slidably connected to the frame 10 and positioned on the front of the workbench 20. The laser main box 30 on the top and the laser motor (not shown) for driving the laser main box 30 to slide, wherein, the specific transmission connection structure between the laser motor and the laser main box 30 is a conventional structure, such as a screw mandrel Assemblies, rack and pinion assemblies or worm gear assemblies, etc., will not be described in detail here. Preferably, the frame 10 is fixedly connected with a vertically arranged scale 12, and the laser main box 30 is provided with an indicator arrow 13 cooperating with the scale 12, which is convenient for the operator to understand and adjust the laser main box 30 on the frame 10. height position.

[0036] The inner cavi...

Embodiment 2

[0042] Such as Figure 4 shown, and refer to Figure 1-Figure 3 , this embodiment provides a laser printing all-in-one machine, which is further improved on the basis of the multi-head laser printing equipment for shoes provided in Embodiment 1, that is, what this embodiment provides is essentially a multi-head laser printing equipment for shoes equipment.

[0043] Specifically, the laser printing all-in-one machine or shoe multi-head laser printing equipment provided in this embodiment also includes a main box 50 vertically slidably connected to the frame 10 and positioned directly above the workbench 20 and a main box 50 for driving The sliding inkjet motor (not shown in the figure), that is, the laser inkjet printer provided in this embodiment or the multi-head laser printing equipment for shoes includes a laser main body that is vertically slidably connected to the frame 10 and is positioned directly above the workbench 20. Box 30 and spray painting main box 50. Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com