A special tool for disassembling clamps in a narrow space and a processing method thereof

A special tool, narrow space technology, applied in the field of machining, can solve the problems of ratchet sleeve wear, time-consuming and laborious, and damage to the body structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

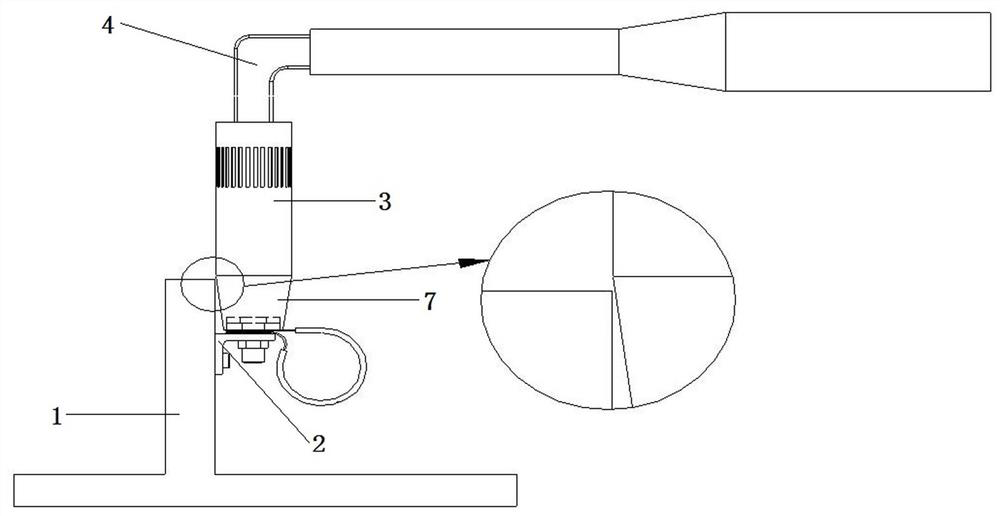

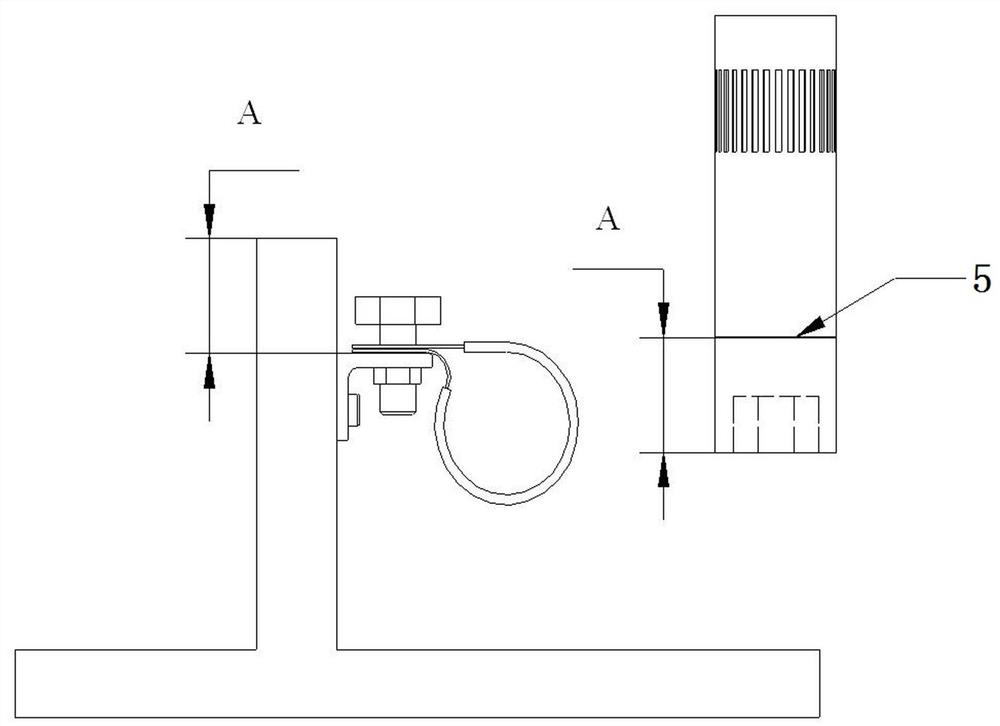

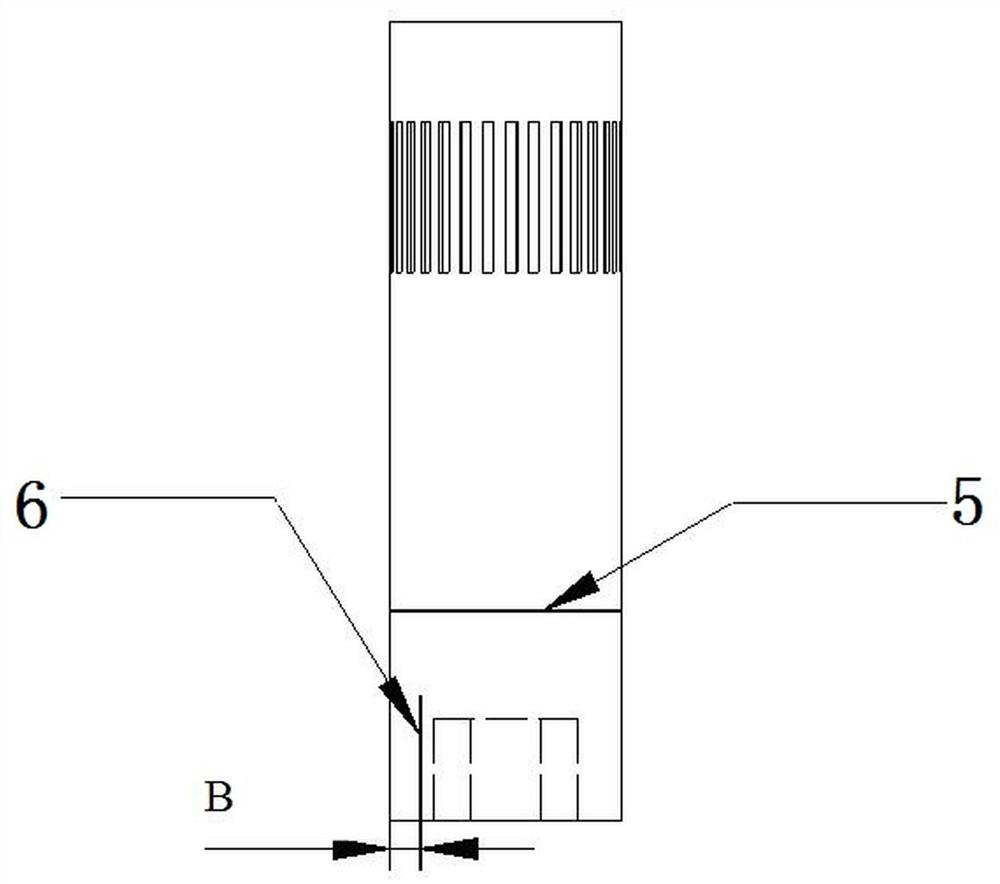

[0032] Embodiment of the present invention as a basic embodiment, the present invention includes a special tool for disassembly clamp narrow space, the sleeve 3 comprises a ratchet and the ratchet 4. One end of the ratchet sleeve 3 and 4 in contact with the ratchet wheel is cylindrical, inner side facing the square hole, one end close to the clamp 2 contracts inwardly to form a conical tapering section 7. The longitudinal contraction of the working section 7 lowest height than the minimum height of 5 theoretical high 0.5mm, the height of the minimum theoretical interference flanges body structure 1 at a position in height relative to the theoretical surface of the upper surface 2 clamps. 4 the ratchet sleeve 3 for screwing the actuating ratchet, the ratchet 4 is L-shaped, one end in contact with the ratchet 3 is the positive square prism sleeve. 4 plus four ratchet ratchet prism 4 in contact with the square holes in the sleeve and the sleeve is connected through.

Embodiment 2

[0034] As a preferred embodiment of the present invention, the present invention includes a dedicated tool in a narrow space for detachably clamp, comprising a ratchet sleeve 3 and the ratchet 4. One end of the ratchet sleeve 3 and 4 in contact with the ratchet wheel is cylindrical, inner side facing the square hole, one end close to the clamp 2 contracts inwardly to form a conical tapering section 7. The longitudinal shrinkage minimum operating section 7 is higher than the lowest height of 5 theoretical height 1.5mm, the height of the minimum theoretical interference flanges body structure at a position on a surface with respect to the theoretical level of the upper surface of the clip 2. 4 the ratchet sleeve 3 for screwing the actuating ratchet, the ratchet 4 is L-shaped, one end in contact with the ratchet 3 is the positive square prism sleeve. 4 plus four ratchet ratchet prism 4 in contact with the square holes in the sleeve and the sleeve is connected through.

[0035] A meth...

Embodiment 3

[0042] As another preferred embodiment of the present invention, referring to the instruction manual figure 1The present invention includes a special tool for disassembling the clipper in a narrow space, including a ratchet sleeve 3 and a ratchet 4. One end of the ratchet sleeve 3 and the ratchet 4 is a cylindrical shape, and the end faces the inner four-square well, and is contracted inwardly near one end of the clamp 2 to form a tapered shrinkage section 7. The longitudinal minimum operating height 5 of the shrinkage segment 7 is 1 mm higher than the theoretical minimum height, the theoretical minimum height is the theoretical height of the upper surface of the upper surface of the body structural edge 1 relative to the clip 2 at the upper surface of the interference position. The ratchet 4 is used to twist the ratchet sleeve 3, the ratchet 4 being L-shaped, one end of the ratchet sleeve 3 is a positive quadrature column. The ratchet 4 is in contact with the inner four-square we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com