Automatic rebar pipe penetrating equipment for insulating rebar production

A technology for automatic threading and insulating pipes, which is applied in the field of automatic equipment for the production of insulating steel bars and automatic pipe threading equipment for steel bars for the production of insulating steel bars, to achieve the effect of reliable positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

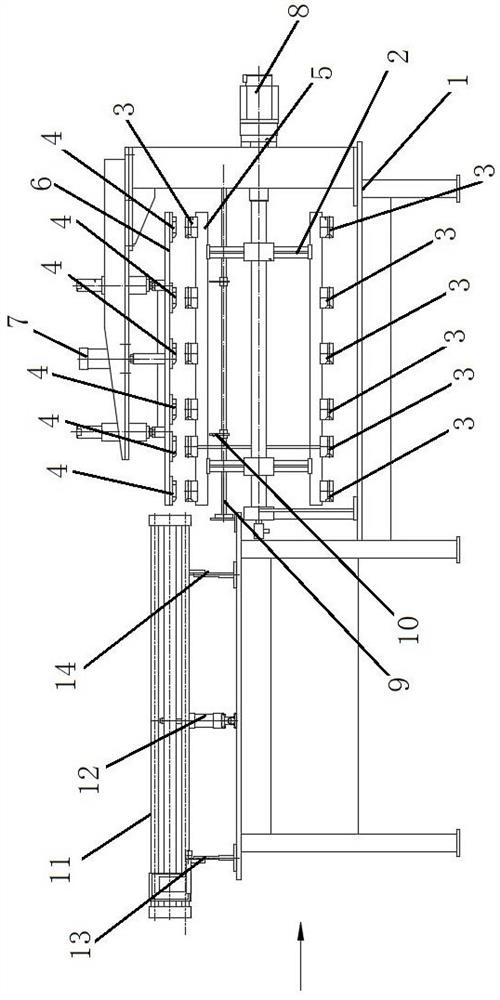

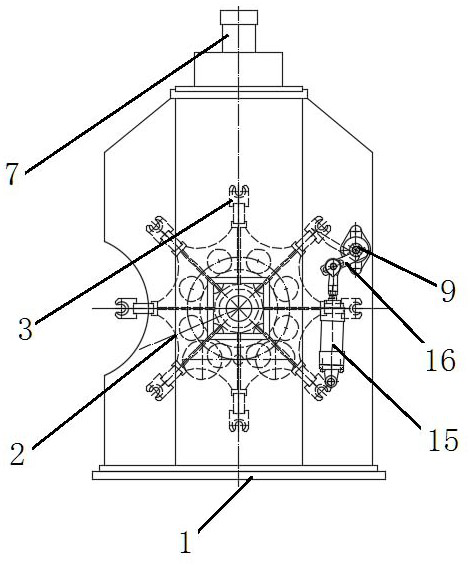

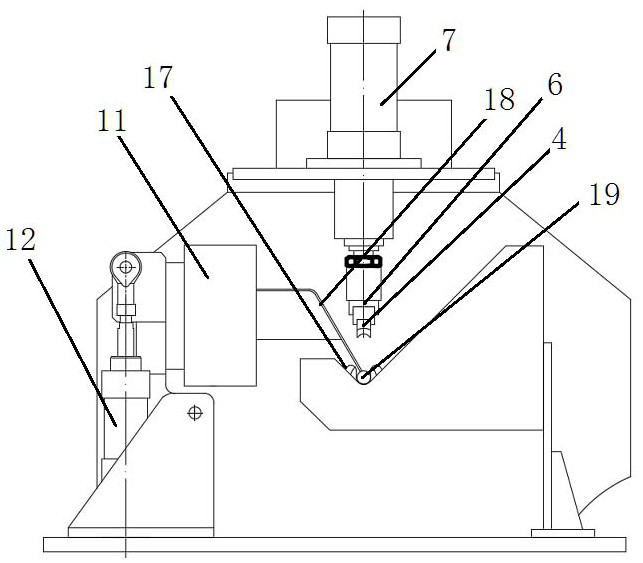

[0021] A further detailed explanation of the present invention is given in conjunction with the accompanying drawings. In the accompanying drawings, each mark is: 1: frame; 2: hub; 3: lower mold; 301: receiving groove; 302: lower arc groove; : guide arc surface; 305: guide tapered mouth of lower mold; 306: air hole; 307: air groove; 308: gasket; 4: upper mold; 401: upper arc groove; 402: guide tapered mouth of upper mold ;5: lower beam; 6: upper beam; 7: upper beam driving cylinder; 8: stepper motor; 9: swing shaft; 10: claw; 11: push cylinder; 12: swing cylinder; : rear bracket; 15: stripping cylinder; 16: swing rod; 17: V-shaped groove; 18: push handle; 19: push plate; 20: guide groove; 21: connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com