Three-dimensional printer frame extending structure

A technology of 3D printer and extended structure, which is applied in the field of 3D printing, and can solve the problems affecting the printing accuracy of the printer body and affecting the normal use of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

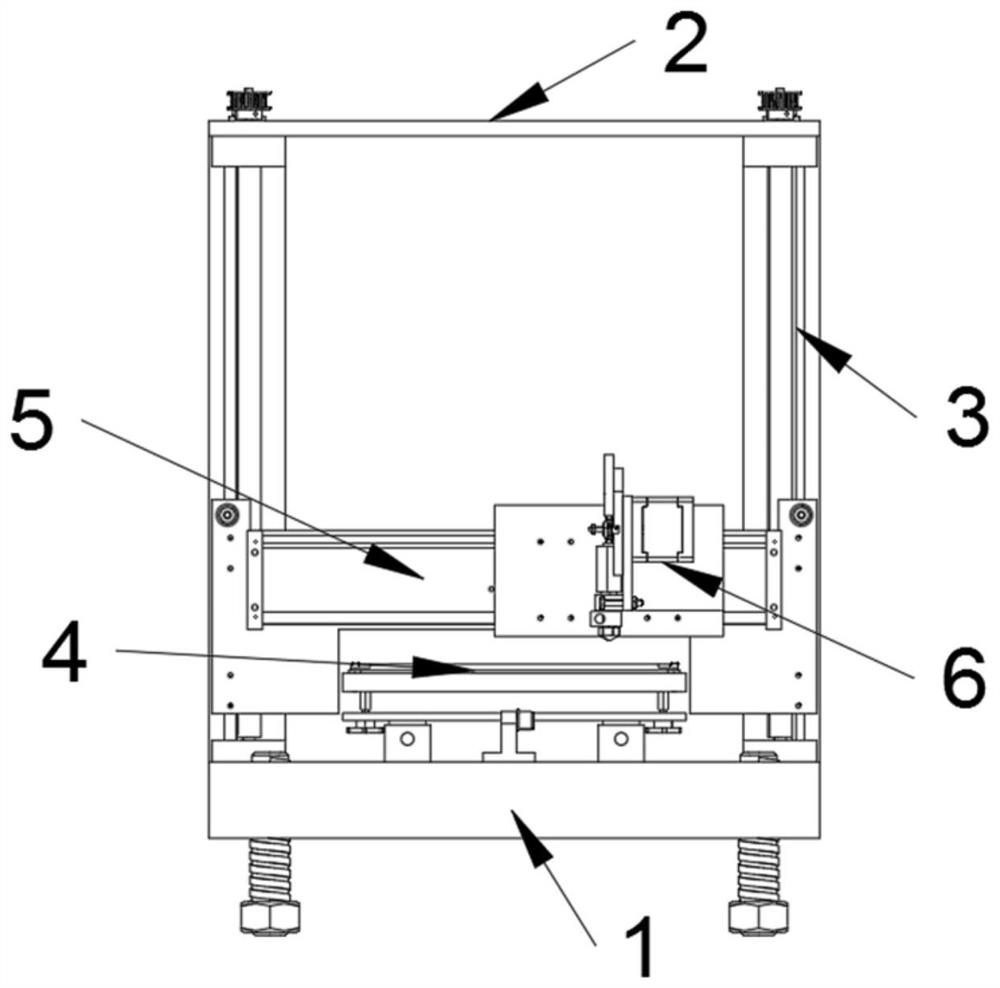

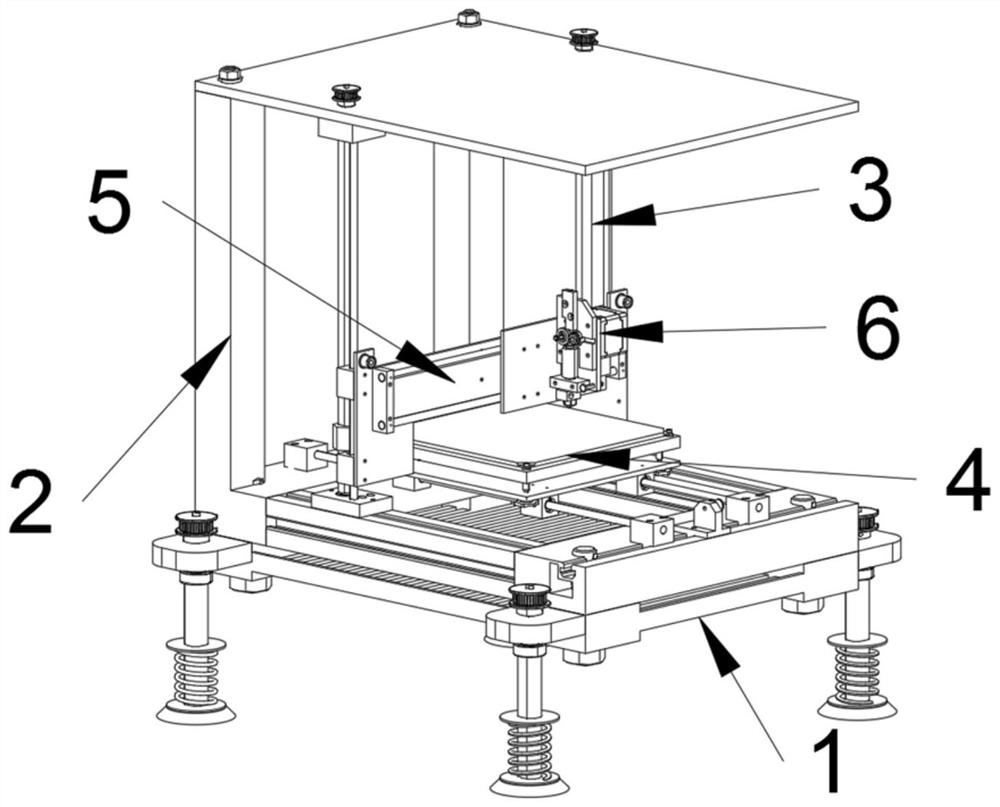

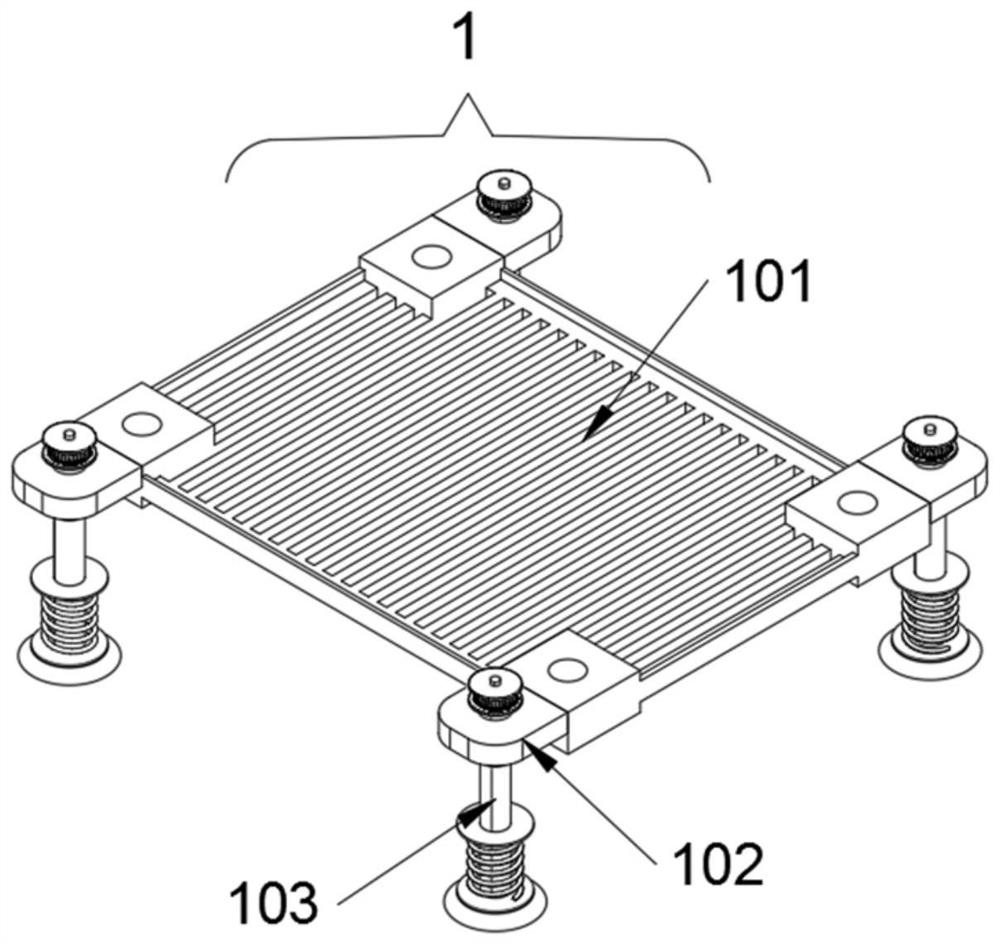

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The present invention provides a three-dimensional printer frame extension structure, including: a chassis mechanism 1, a platen mechanism 4, an adjustment mechanism 5, and a printing device 6. The top of the chassis mechanism 1 and the bottom of the support mechanism 2 are fixedly connected by screws; the chassis Mechanism 1 includes a connecting frame 101, a leaf plate 102, and legs 103. A leaf plate 102 is provided at the front end and the rear end of the left and right sides of the connecting frame 101, and a through hole is provided in the middle of the top surface of the leaf plate 102. The top of 103 is fixedly connected in the through hole of the leaf plate 102 by screws; a guide rail mechanism 3 is symmetrically arranged on the left and right sides inside the bracket mechanism 2; the platen mechanism 4 is slidingly connected to the middle position of the top of the bracket mechanism 2; In the middle pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com