Sputter coating machine and sputter coating method

A coating machine and sputtering technology, which is applied in the display field, can solve the problems of sputtering coating cost increase, outer frame thickness thinning, cleaning difficulty, etc., and achieve the effects of low coating cost, improved replacement efficiency, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

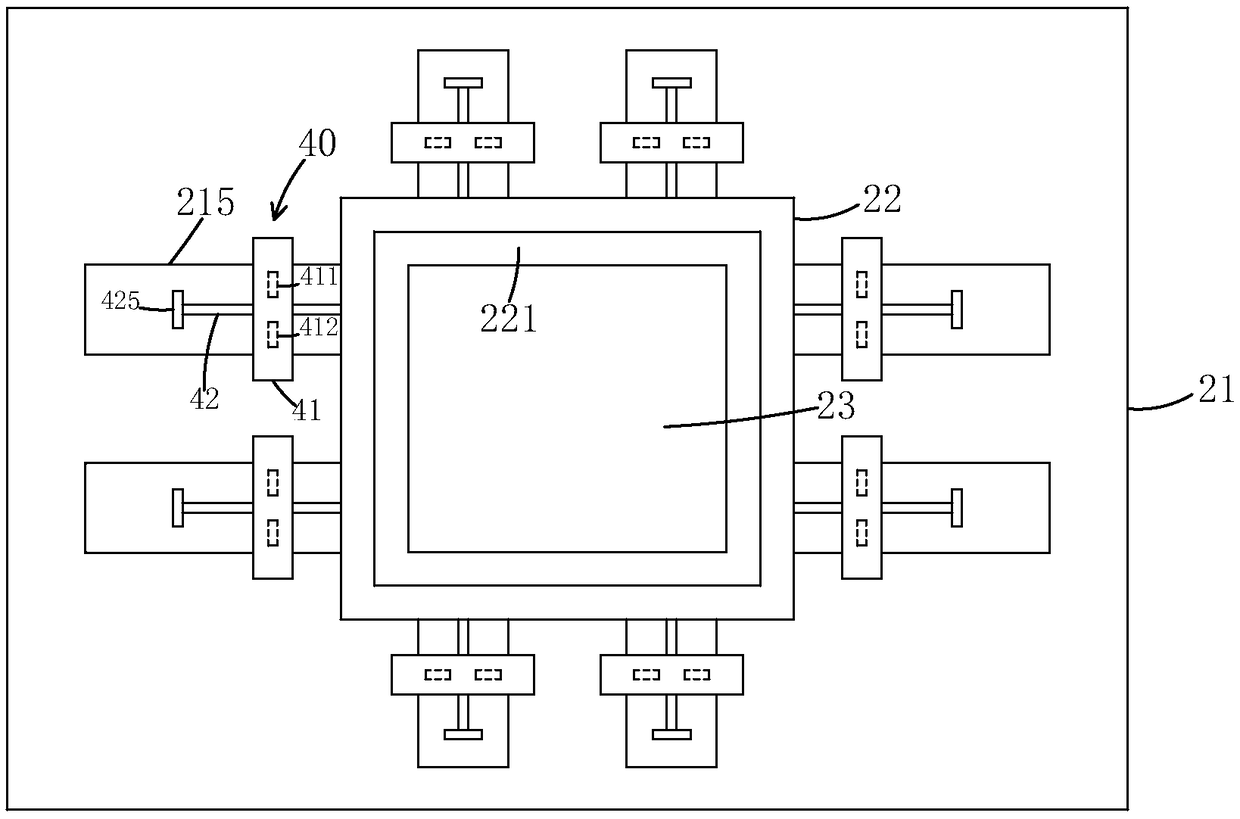

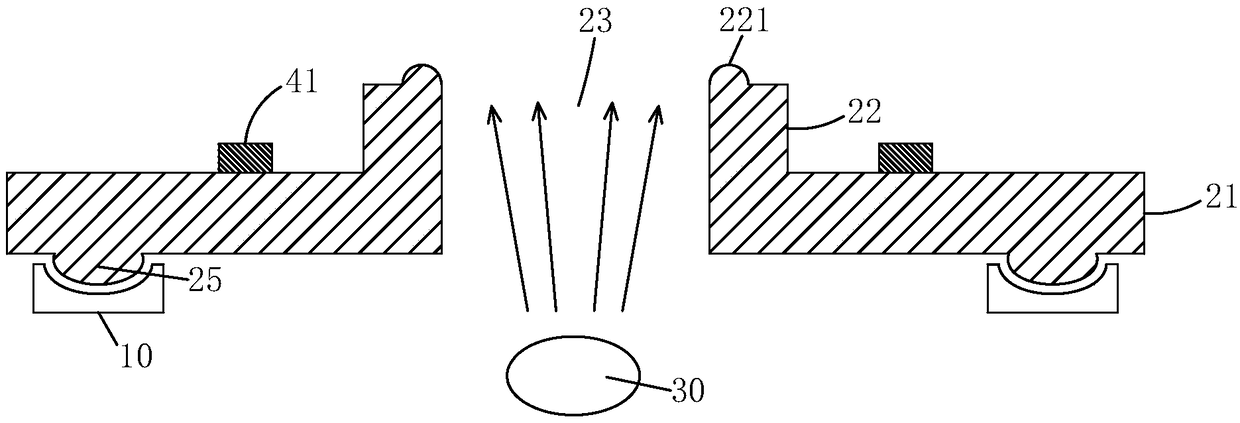

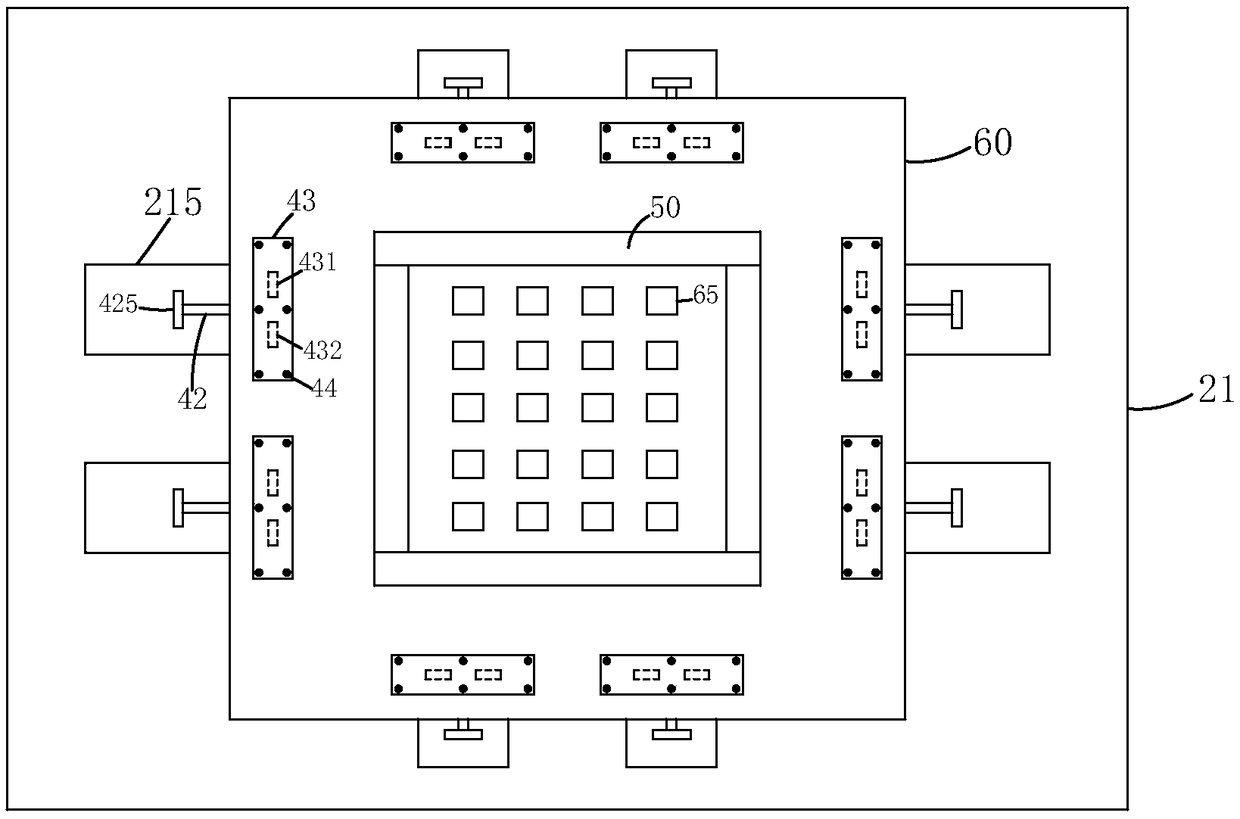

[0047] see Figure 1 to Figure 6 , the present invention provides a sputter coating machine, comprising:

[0048] track 10;

[0049] A carrying device 20 arranged on the track 10 and movable along the track 10, the carrying device 20 includes a frame-shaped base plate 21, a frame connected to the frame-shaped base plate 21 from the inside of the frame-shaped base plate 21 Shaped boss 22, and the frame-shaped opening 23 that is positioned at described frame-shaped boss 22 inner sides; Described frame-shaped substrate 21 is provided with several grooves 215 that are distributed around described frame-shaped boss 22;

[0050] a target 30 corresponding to the frame-shaped opening 23;

[0051] A plurality of fastening and tensioning devices 40 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com