Structure of longitudinal beam wheel casing area for improving front collision performance

A front longitudinal beam and front wheel technology, applied in the superstructure, superstructure sub-assembly, transportation and packaging, etc., can solve the problem of ineffective collision force transmission, reduce impact, absorb collision energy, reduce The effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment proposes a structure of the longitudinal beam wheel house area of the automobile, so that the front wheel house side reinforcement beam can fully transmit and absorb the collision energy generated in the front collision process in the front collision condition, so as to reduce the baffle The amount of intrusion reduces the degree of occupant injury.

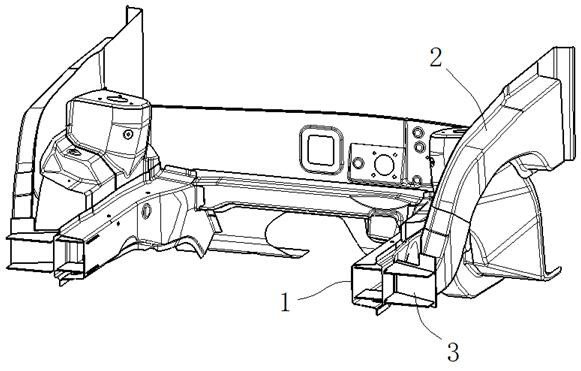

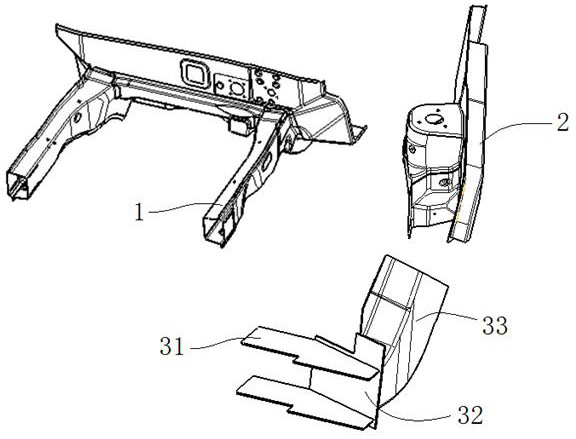

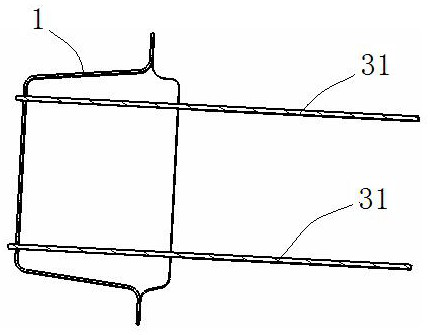

[0021] Such as Figure 1~4 As shown, the structure of the longitudinal beam wheel housing area of the automobile in this embodiment includes a front longitudinal beam 1, a front wheel housing side reinforcement beam rear assembly 2 and a connecting member 3, wherein:

[0022] The connecting member 3 is formed by fixedly connecting the reinforcement crossbeam with the front part assembly 33 of the front wheelhouse side reinforcement beam. The wheel house side reinforcing beam front assembly 33 is a cylindrical structure, and is welded and fixed to the rear end surface of the baffle plate 32 .

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com