Longitudinal hatch coaming toe end of bulk cargo ship

A hatch coaming, bulk carrier technology, applied in the direction of the hull, hull deck, hull parts, etc., can solve the problems of increasing construction volume, and achieve the effect of avoiding sudden changes, continuous structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be more clearly and completely described with reference to a preferred embodiment and in conjunction with the accompanying drawings.

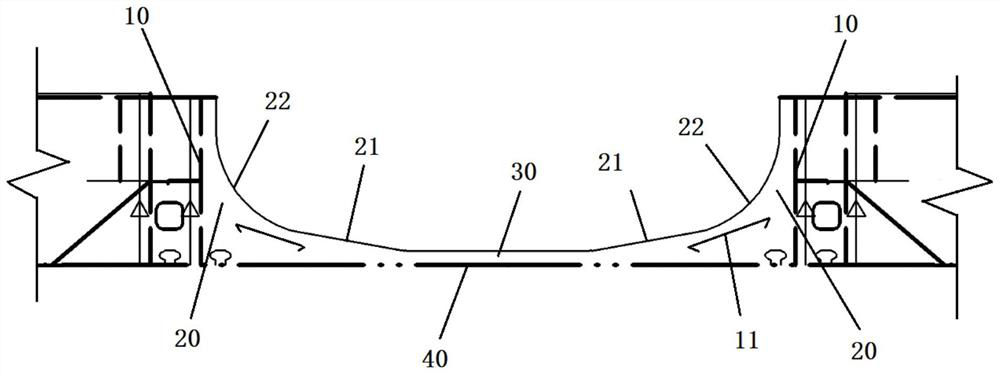

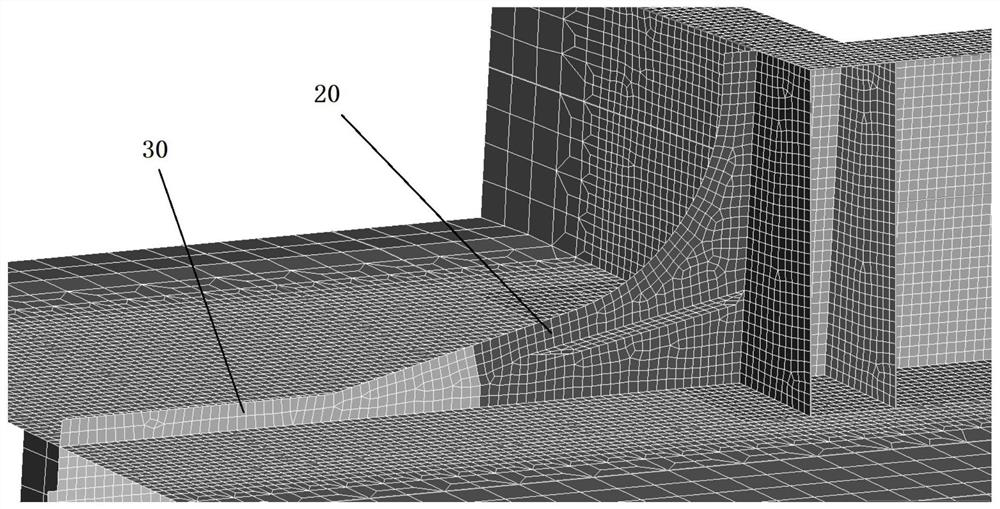

[0021] like figure 1 As shown, a longitudinal hatch coaming toe end of a bulk carrier is arranged between two adjacent hatch coaming longitudinal plates 10; each of the two hatch coaming longitudinal plates 10 is fixed with a toe end plate 20 , the two toe end plates 20 are connected by a rectangular plate 30 .

[0022] The rectangular plate 30 and the two toe end plates 20 lie on the same plane.

[0023] The lower end of the rectangular plate 30 is fixed to the deck 40 , and the edge line of the upper end of the rectangular plate 30 is parallel to the deck 40 . The distance from the upper edge line of the rectangular plate 30 to the deck 40 is less than 150 mm.

[0024] The lower end of the toe end plate 20 is fixedly connected to the deck 40 , the upper end edge line of the toe end plate 20 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com