Feeding device and production line

A feeding device and material technology, applied in the direction of lifting device, transportation and packaging, lifting frame, etc., can solve the problems of improper placement of materials, time-consuming and labor-intensive handling, and heavy materials, so as to reduce labor intensity and take less The effect of taking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

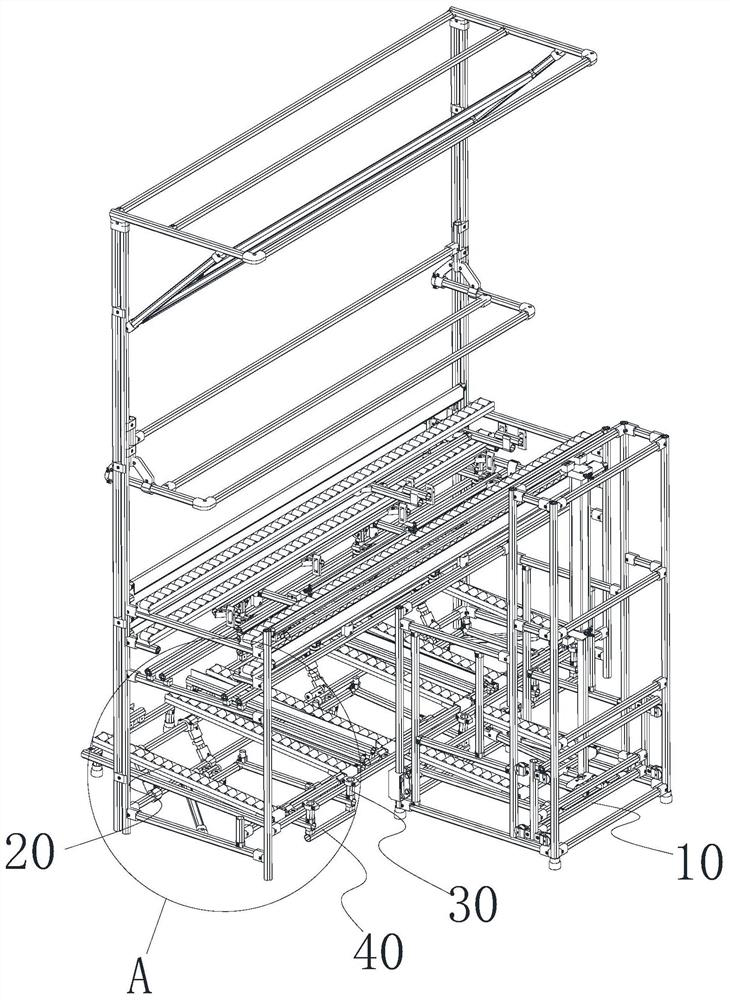

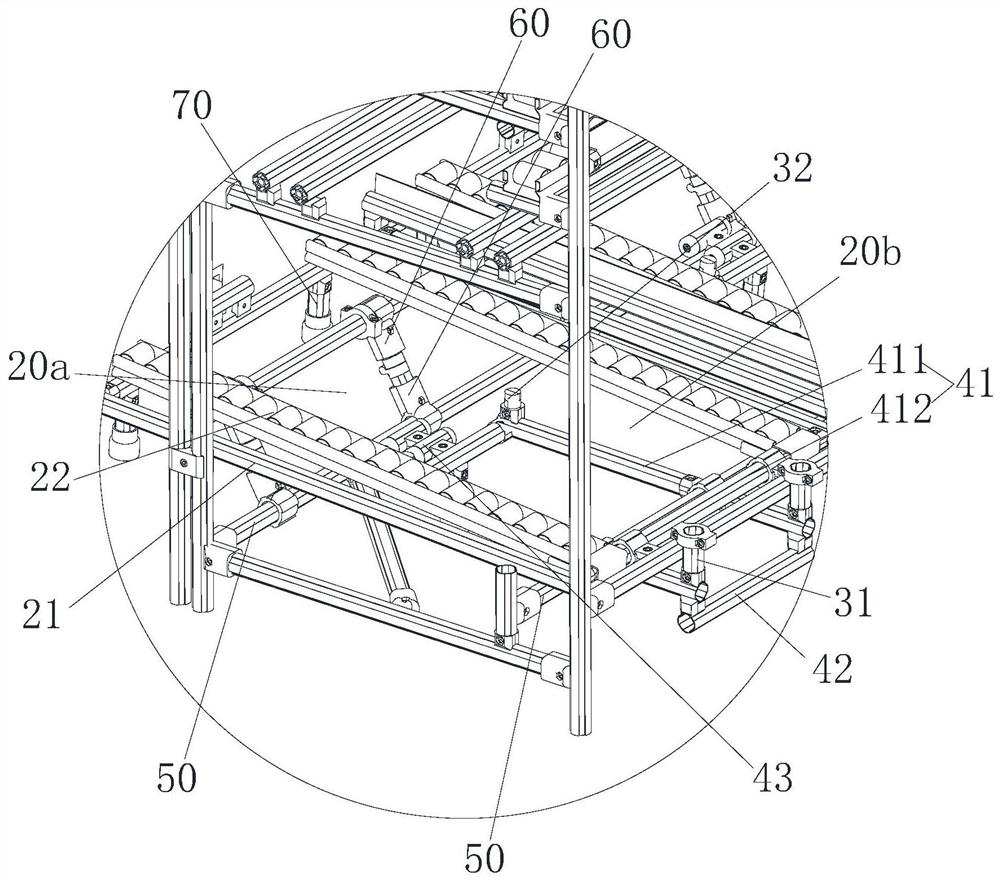

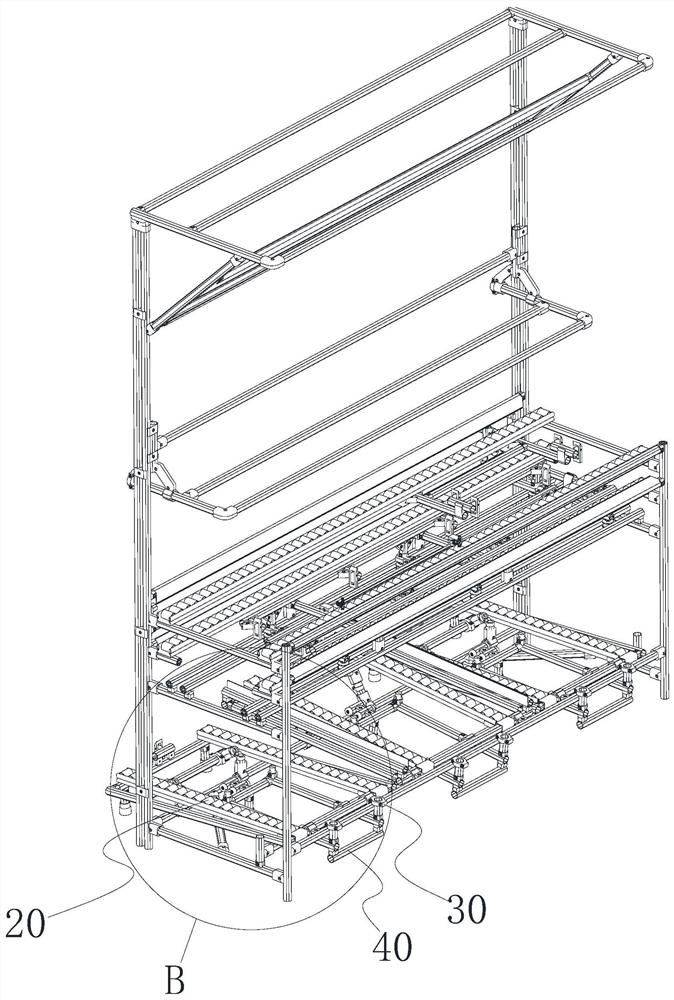

[0023] Such as Figure 1 to Figure 4 As shown, the present invention discloses a feeding device, including a lifting platform 10 and a transmission mechanism 20, the lifting platform 10 is used to place materials, the lifting platform 10 has a starting position and a pick-up position, and the pick-up position is higher than the starting position , the lifting platform 10 switches between the starting position and the pick-up position by rising or falling; It is used to transfer materials to the lifting platform 10 located at the starting position. The feeding device of the present invention can transfer the material to the lifting platform 10 by setting the transmission mechanism 20, and then the lifting platform 10 lifts the material to the pick-up position, which is located at a height that is convenient for the operator to pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com