Gold ore powder circulating and gold powder refining equipment

A gold ore and powder technology, which is applied in the field of gold ore powder recycling gold powder refining equipment, can solve the problems of mercury waste and human hazards, and achieve the effects of high automation, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

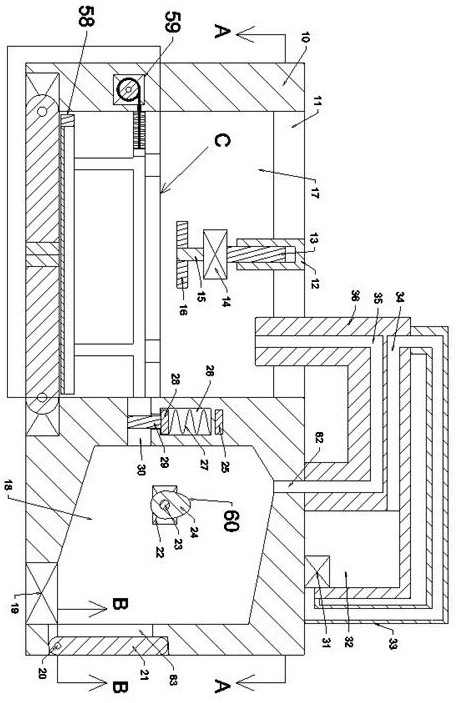

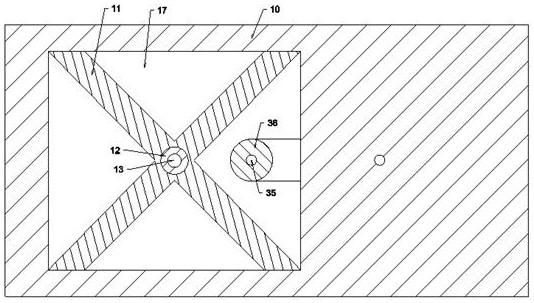

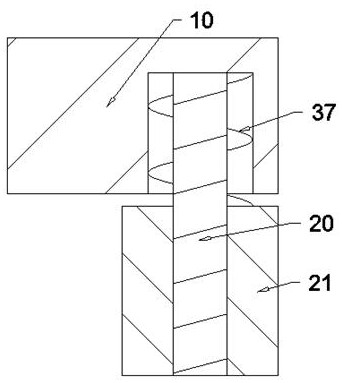

[0018] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0019] combined with Figure 1-5 The described a kind of gold ore powder circulating gold powder refining equipment comprises a box body 10, and the inside of the box body 10 is provided with a mixing and filtering chamber 17, and the inside of the mixing and filtering chamber 17 is provided with a gold collecting mechanism 58, and the inside of the mixing and filtering chamber 17 is provided with a gold collection mechanism 58, and the said mixing and filtering chamber 17 is provided with a gold collecting mechanism 58 respectively. The horizontal chute 48 and the vertical chute 49 of the front and back side inner walls of the mixing filter cavity 17, the horizontal chute 48 commun...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap