Method for uranium purification circulation in Purex process

A process and pretreatment technology, applied in the field of uranium purification cycle, can solve the problems of great influence of acidity and temperature, unsatisfactory purification effect, danger, etc., to strengthen the removal effect, improve the purification effect, and enhance the removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

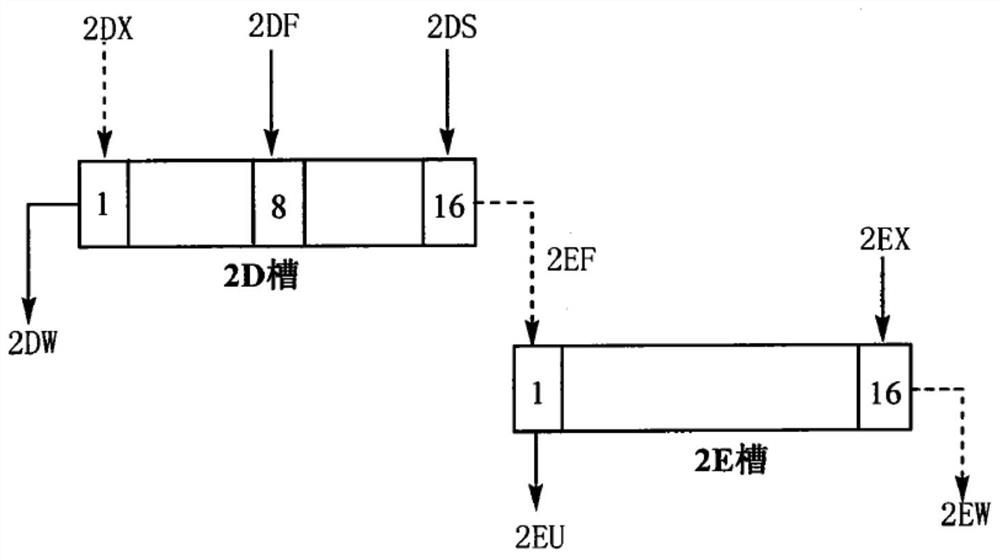

[0017] figure 1 is a flow diagram of a method for uranium purification cycle in an exemplary Purex process of the present invention. Add hydrazine nitrate and nitric acid to the 1CU feed liquid from the first cycle, so that the acidity of the feed liquid is 0.2 mol / L, and the concentration of hydrazine nitrate is 0.2 mol / L, then heat the feed liquid to 85°C, keep it warm for 2.5 hours, and adjust the acidity after cooling Then it will be used as 2DF (the uranium concentration in 2DF is 50g / L, and the acidity is 2.0mol / L). 2DS is 1.0mol / L nitric acid + 0.2mol / L hydroxysemicarbazide, 2D tank adopts 8 stages of extraction and 8 stages of washing, flow ratio 2DF:2DX:2DS=1:0.7:0.15. According to the analysis results of the experimental samples, the uranium yield of the 2D tank is greater than 99.97%, the plutonium purification factor is greater than 800, and the plutonium content in 2EU is less than 6.71×10 -9 (g / gU), meeting the uranium product index requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com