Fabricated steel keel foam concrete wallboard mounting structure

A foam concrete and installation structure technology, which is applied to walls, building components, building structures, etc., can solve the problems of inconvenient installation of foam concrete slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is attached Figure 1-6 The application is described in further detail.

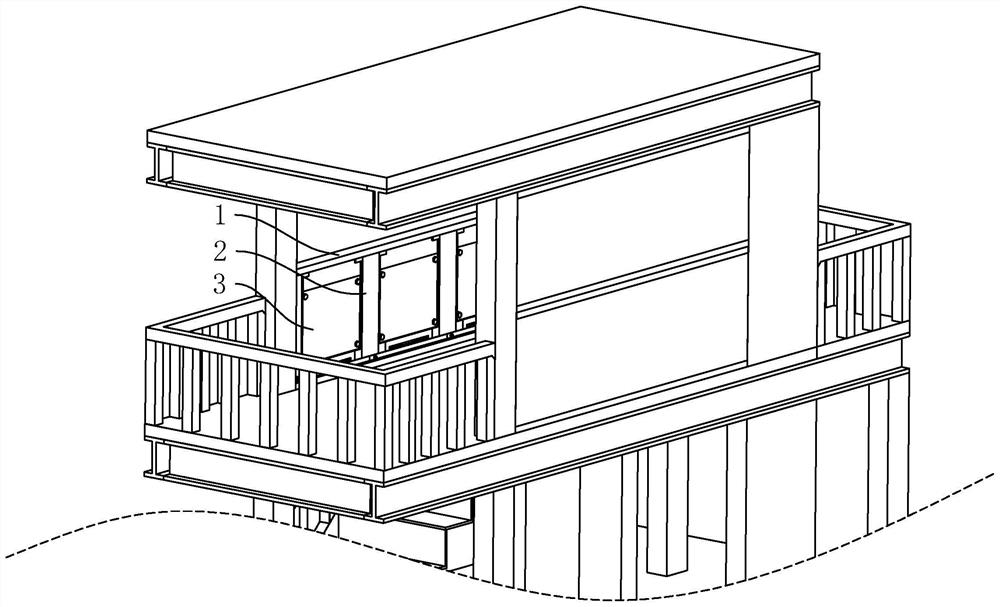

[0035] The embodiment of the present application discloses a fabricated steel keel foam concrete wall panel installation structure. refer to figure 1 , a prefabricated steel keel foam concrete wall panel installation structure, including several horizontal keels 1, vertical keels 2, and foam concrete wall panels 3, the foam concrete wall panels 3 are formed by pouring foam concrete inside a metal frame, and the horizontal keels 1 and The vertical keel 2 is fixedly connected, and the horizontal keel 1 is used for installing the exterior wall decorative panels of the interior and exterior walls.

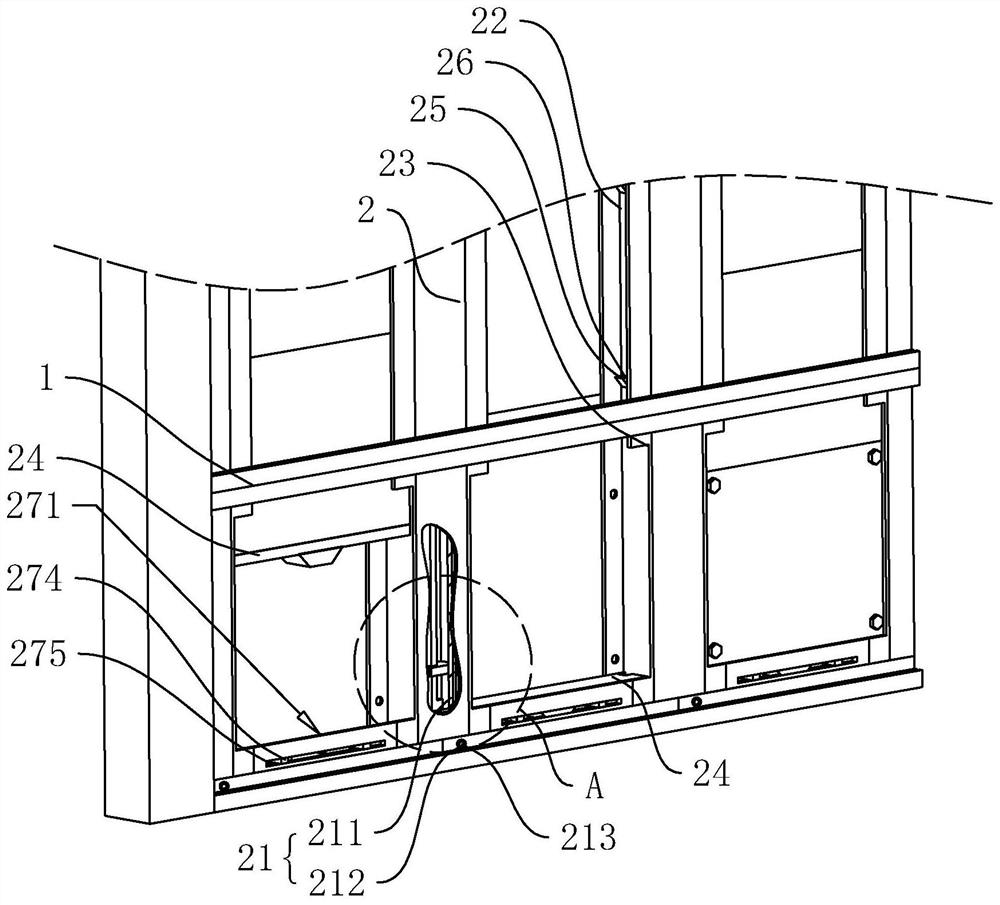

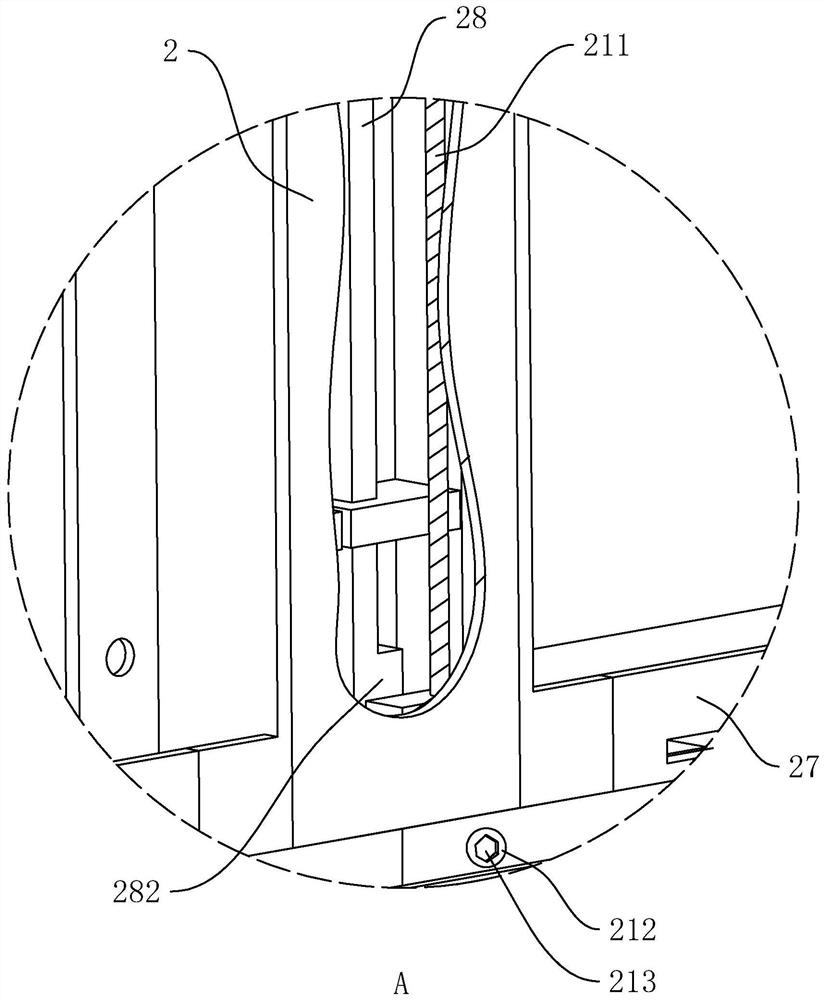

[0036] refer to figure 2 , the vertical keel 2 is slidingly provided with a lifting platform 24, and the lifting platform 24 is located between two adjacent vertical keels 2, and the lifting platform 24 is installed in the vertical keel 2 to drive the driving platform 24 to slide along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com