Pipe wrapping device for wrapping electromechanical wire pipe in masonry structure and construction method thereof

A masonry structure and construction method technology, which is applied to the processing of building components, building structures, and building materials, can solve the problems of poor wall perception, large amount of repairs, low pass rate of wall flatness, etc., and achieve improvement The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The following embodiments illustrate the technical solutions of the present invention in detail. The following embodiments are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, and cannot be construed as limitations on the technical solutions of the present invention.

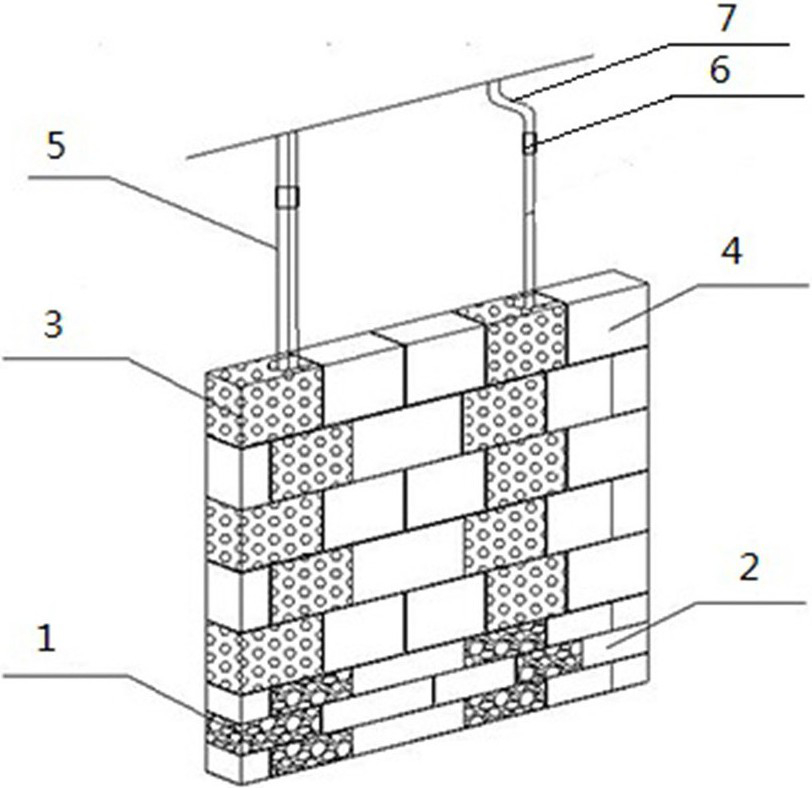

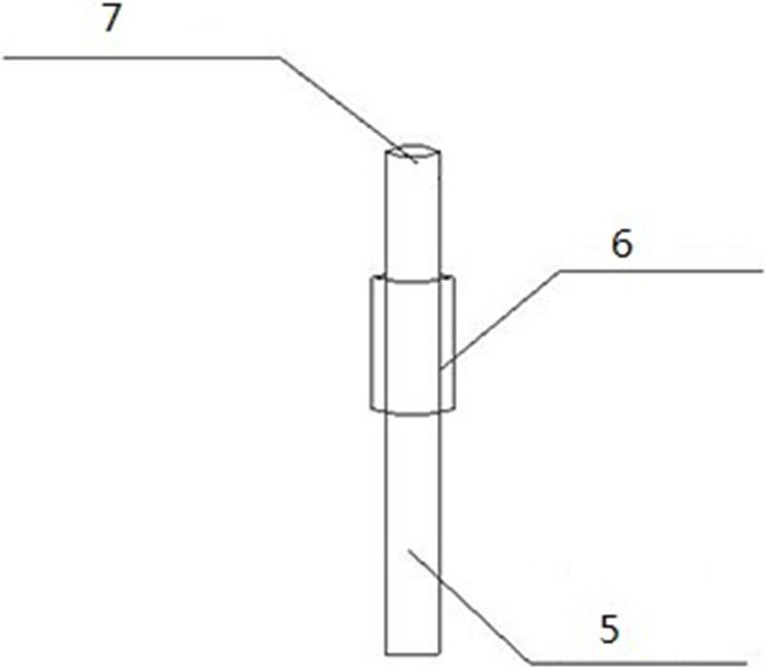

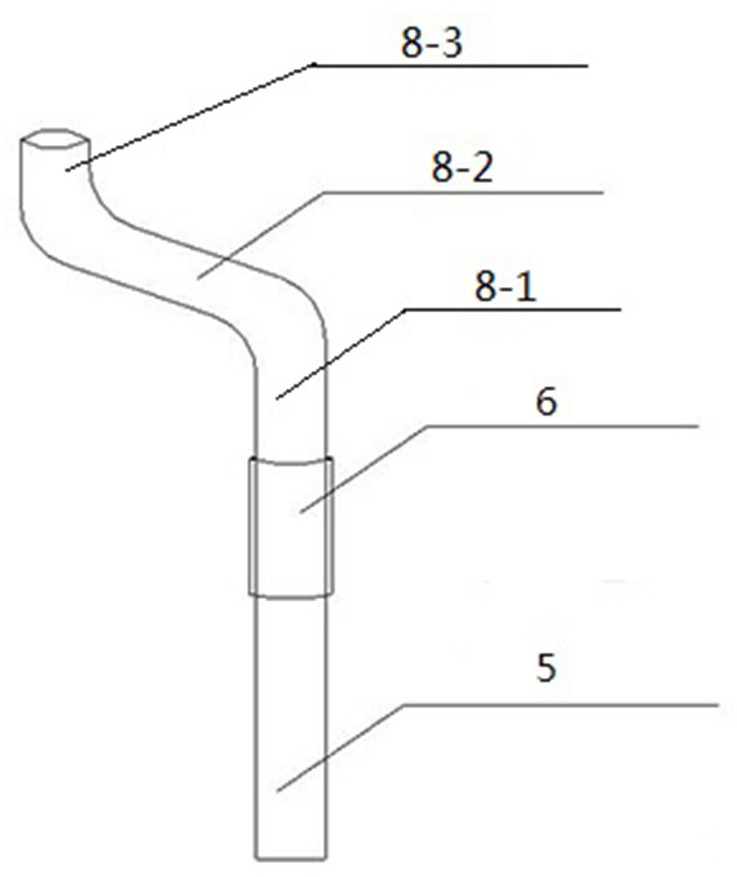

[0038]Such asfigure 1 , A kind of guaranteeing device for the wire and tube of the masonry structure wrapping machine, including the V-shaped tube brick 1, the solid brick 2, the U-shaped tube brick 3, the porous brick 4 and the embedded straight tube 5, the end of the V-shaped tube brick 1 A V-shaped groove 1-1 that penetrates in the vertical direction is provided. The end of the U-shaped cladding brick 3 is provided with a U-shaped groove 3-1 that traverses in the vertical direction. The V-shaped cladding brick 1 and the solid brick 2 are built on the basis. U-shaped cladding brick 3 and perforated brick 4 are built on the top of the foundation. V-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap