Microfluidic flow velocity detection device based on conductive characteristic change

A technology of conductive characteristics and detection devices, which is applied in the field of microfluidic flow rate detection devices based on changes in conductive characteristics, can solve problems such as low precision, and achieve the effect of high flow rate detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

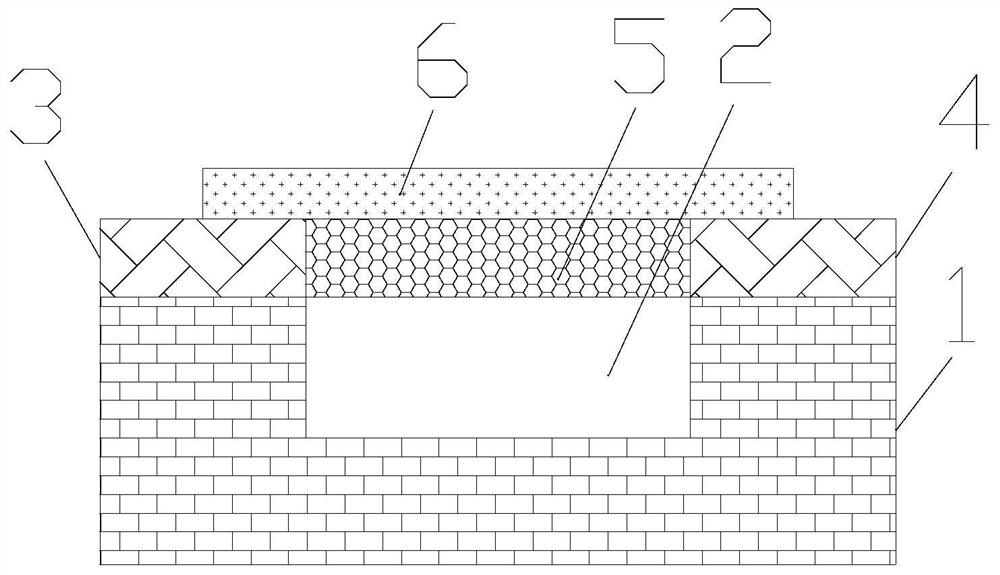

[0020] The invention provides a microfluidic flow velocity detection device based on the change of conductivity characteristics. Such as figure 1 As shown, the microfluidic flow rate detection device based on the change of conductive characteristics includes a microfluidic chip 1 , a first metal part 3 , a second metal part 4 , a first conductive part 5 , and a flexible layer 6 . A fluid channel 2 is provided on the surface of the microfluidic chip 1 . The first metal part 3 and the second metal part 4 are arranged on both sides of the fluid channel 2 respectively, and the material of the first metal part 3 and the second metal part 4 is gold. The first conductive part 5 is fixed between the first metal part 3 and the second metal part 4 . The first conductive part 5 is a rectangle, and the long side of the rectangle is along the connecting line direction between the first metal part 3 and the second metal part 4 . That is to say, the first conductive part 5 is similar to a...

Embodiment 2

[0023] On the basis of Embodiment 1, the first conductive part 5 and the flexible layer 6 are fixedly connected. In this way, driven by the flexible layer 6, the deformation of the first conductive part 5 is more, and the stress in the first conductive part 5 changes more, so the conductive characteristics of the first conductive part 5 change more, thereby realizing more High-precision flow rate detection.

Embodiment 3

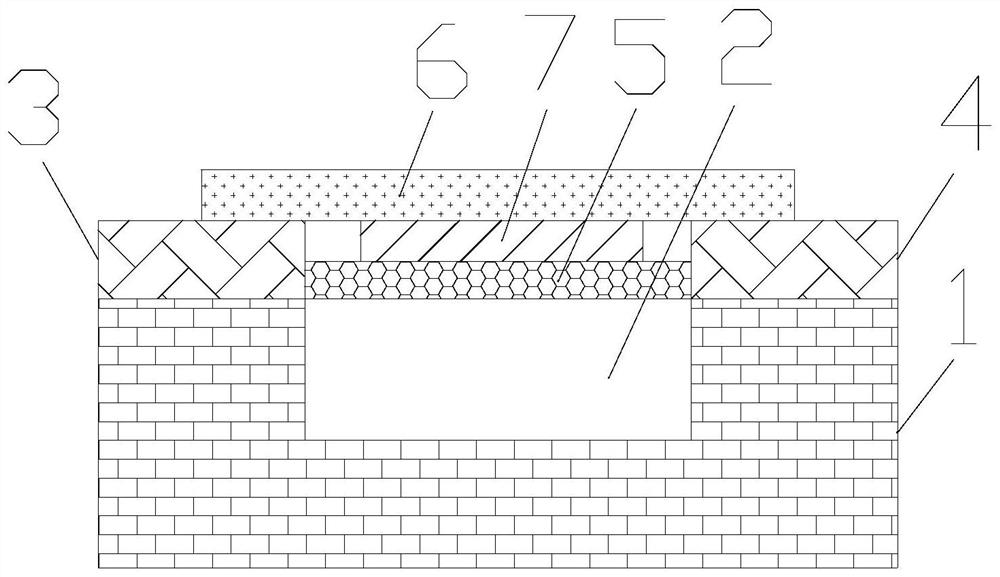

[0025] On the basis of Example 1, such as figure 2 As shown, a second conductive part 7 is also included, and the second conductive part 7 is fixed on the side of the fluid channel 2 of the flexible layer 6 . That is, if figure 2 As shown, the second conductive part 7 is fixed on the lower side of the flexible layer 6 . The material of the second conductive portion 7 is a semiconductor material. The second conductive part 7 is in contact with the first conductive part 5 . A heterojunction is formed between the first conductive portion 5 and the second conductive portion 7 . Under the action of the fluid, when the flexible layer 6 bends outward, the second conductive part 7 and the first conductive part 5 are gradually separated. Because the heterojunction seriously affects the conductive properties of graphene, this embodiment has the advantage of high detection accuracy of flow velocity.

[0026] Furthermore, the semiconductor material is graphene. In this way, a homo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com