Microfluidic flow velocity detection device based on magnetic principle

A detection device and microfluidic technology, applied in measurement devices, fluid velocity measurement, fluid controllers, etc., can solve problems such as low accuracy, and achieve the effect of high velocity detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

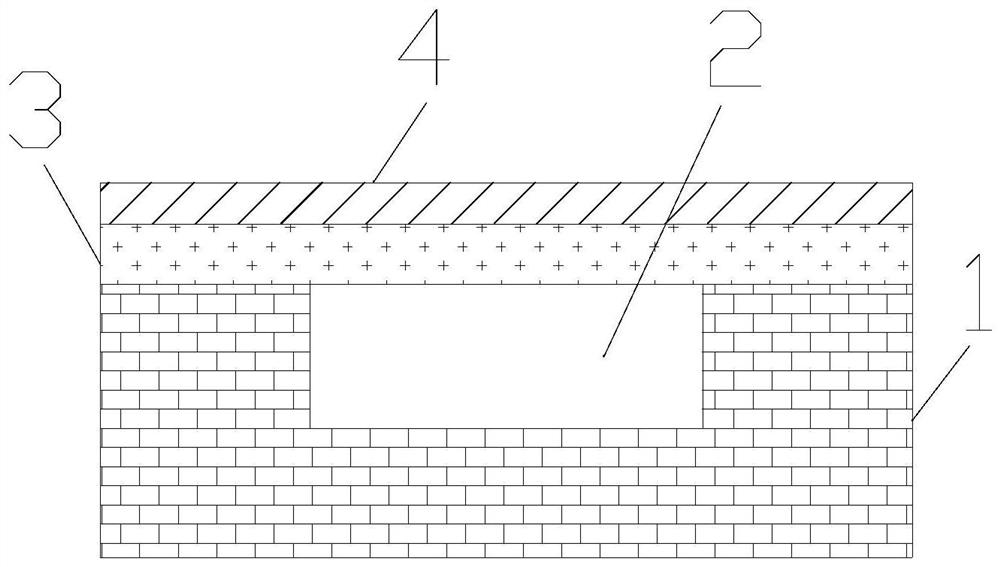

[0021] The invention provides a microfluidic flow velocity detection device based on the magnetic principle. like figure 1 As shown, the microfluidic flow rate detection device based on magnetic principles includes a microfluidic chip 1 , a flexible layer 3 , and a magnetic material part 4 . A fluid channel 2 is provided on the surface of the microfluidic chip 1 . The flexible layer 3 covers the fluid channel 2 , and the flexible layer 3 is respectively provided with openings at the inlet and outlet of the fluid channel 2 . The material of the flexible layer 3 is polydimethylsiloxane. The surface tension of polydimethylsiloxane is small, and under the action of fluid, polydimethylsiloxane can bend outwards more. In addition, polydimethylsiloxane has good chemical stability and is suitable for a wider variety of fluids. The magnetic material part 4 is strip-shaped, the magnetic material part 4 is placed on the flexible layer 3 , and the magnetic material part 4 straddles th...

Embodiment 2

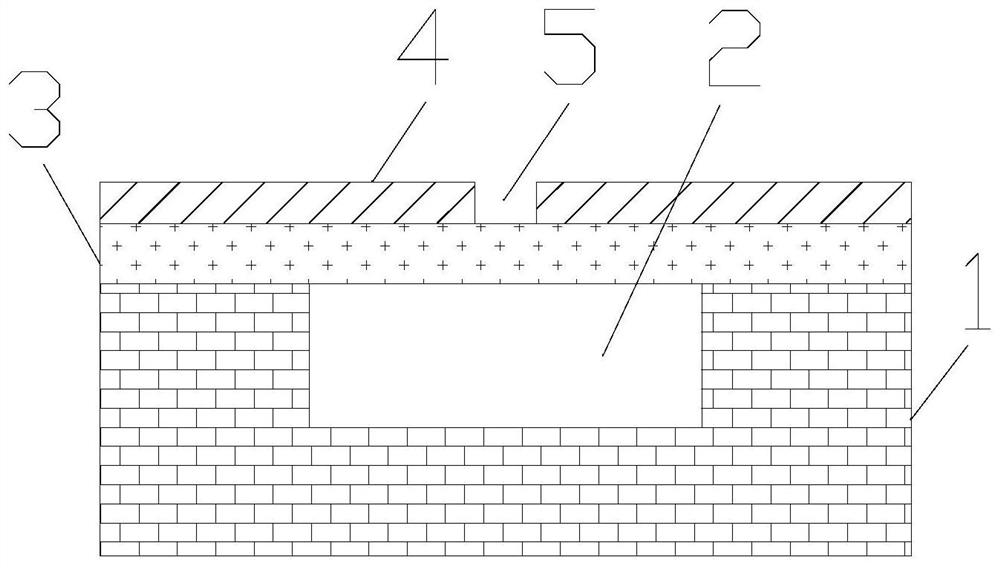

[0024] On the basis of Example 1, such as figure 2 As shown, a gap 5 is provided in the magnetic material portion 4 . The slit 5 is placed in the middle of the fluid channel 2 on the flexible layer 3 . Preferably, the width of the gap 5 is less than 10 microns. More preferably, the width of the gap 5 is close to zero. In this way, under the action of the fluid, when the flexible layer 3 bends outward, the width of the gap 5 increases, seriously increasing the reluctance of the magnetic material part 4, thereby improving the accuracy of flow velocity detection. When the slit 5 is placed in the middle of the fluid channel 2 on the flexible layer 3, under the action of the fluid, the width of the slit 5 increases the most, thereby changing the reluctance of the magnetic material part 4 the most, thereby further improving the flow rate detection. accuracy.

Embodiment 3

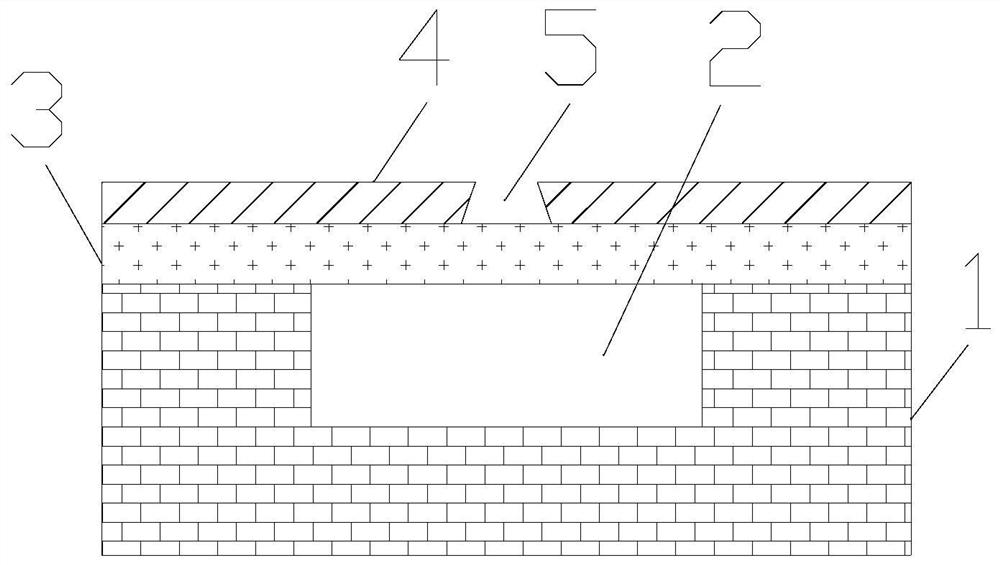

[0026] On the basis of Example 2, such as image 3 As shown, the cross section of the slot 5 is trapezoidal. On the side of the flexible layer 3 , the bottom of the trapezoid is long; on the side away from the flexible layer 3 , the bottom of the trapezoid is short. That is, in image 3 Among them, the lower base of the trapezoid is long; the upper base of the trapezoid is short. Within the gap 5, the magnetic field lines are concentrated near the short sides of the trapezoid. When the flexible layer 3 bends outward under the action of the fluid, the distance between the short sides of the trapezoid changes more, resulting in more changes in the reluctance between the two ends of the magnetic material part 4, thereby improving the accuracy of flow velocity detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com