A grounding structure and connector

A grounding structure and connector technology, which is applied to the connection, the parts of the connecting device, the protective grounding/shielding device of the connecting parts, etc., can solve the problems of poor stability and easy shaking of the contact arm 502, and reduce the probability of shaking, Ensure normal use, improve stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment provides a grounding structure, which can improve the stability of the contact arm structure, thereby ensuring the effect of electrical contact between the contact arm structure and the ground terminal.

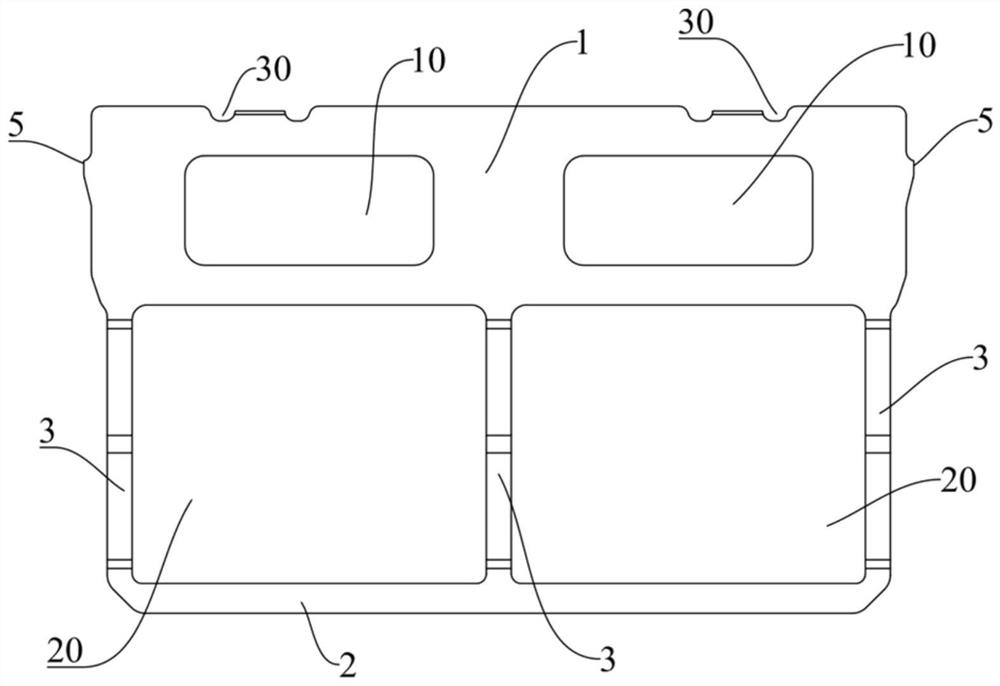

[0063] like Figure 1 to Figure 7 As shown, the grounding structure includes a first support portion 1 , a second support portion 2 and a contact arm structure 3 , wherein the first support portion 1 and the second support portion 2 are disposed opposite to each other. There are a plurality of contact arm structures 3 , one end of each contact arm structure 3 is fixedly connected to the first support portion 1 , the other end of each contact arm structure 3 is fixedly connected to the second support portion 2 , and the contact arm structure 3 is used to make electrical contact with the ground terminal of the connector.

[0064] In the grounding structure provided in this embodiment, the grounding structure includes a first support portion 1, a second s...

Embodiment 2

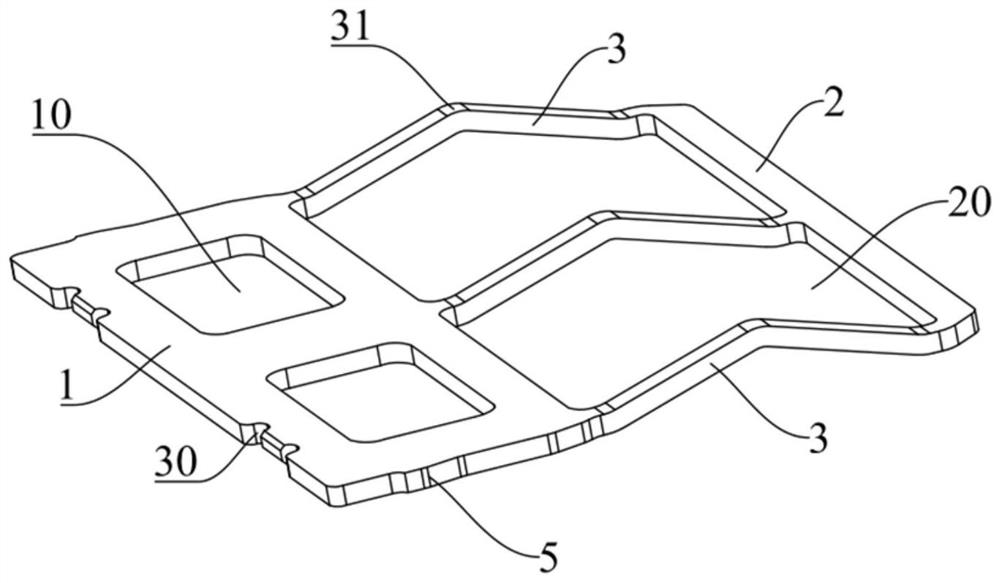

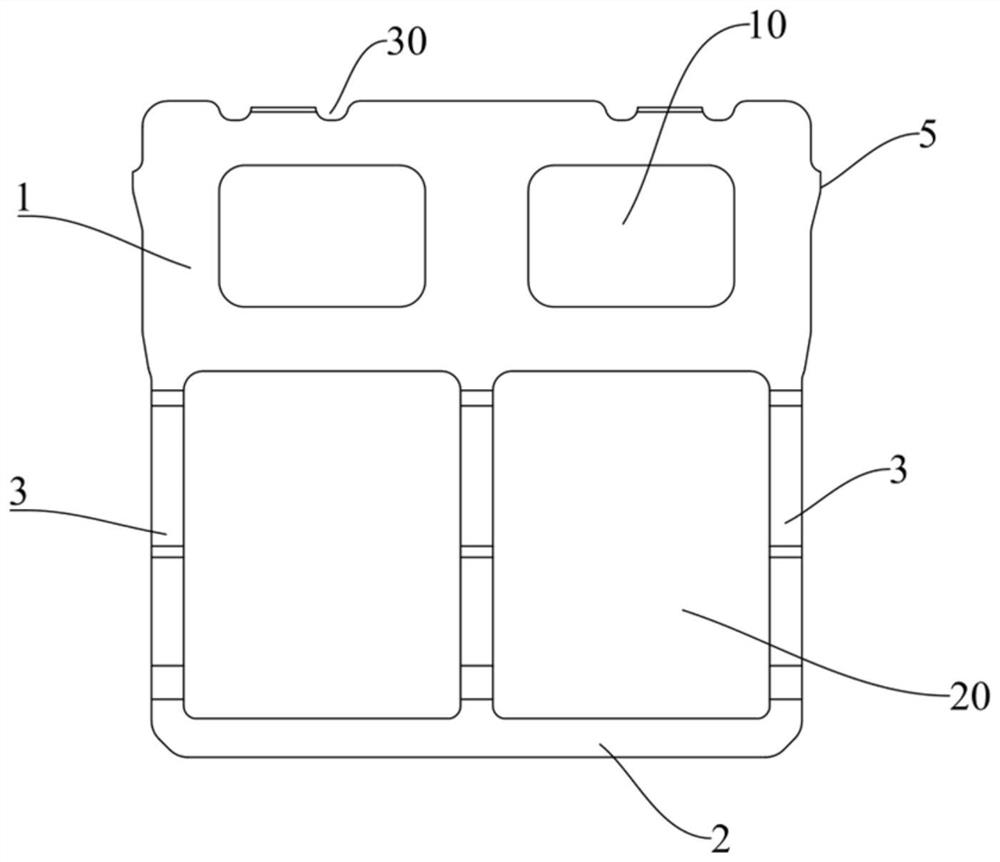

[0084] The difference between the grounding structure in the present embodiment and the grounding structure of the first embodiment is that the second support portions 2 are provided on both sides of the first support portion 1 .

[0085] Specifically, as Figure 8 to Figure 12 As shown, there are multiple second support parts 2, one first support part 1, and two opposite sides of the first support part 1 (ie, the first side and the second side of the first support part 1) are provided with For the second support portion 2, the first support portion 1 and each of the second support portions 2 are fixedly connected by the contact arm structures 3, that is, a part of the contact arm structures 3 among the plurality of contact arm structures 3 are located in the first support portion 1, and is fixedly connected with the second support part 2 located on the first side of the first support part 1, and another part of the contact arm structure 3 is located on the second side of the ...

Embodiment 3

[0091] This embodiment also provides a connector, such as Figures 13 to 26 As shown, the connector includes an insulating housing 100, a conductive terminal 200, and the grounding structure 300 in the first and second embodiments above. That is, the connector may only include the grounding structure 300 in the first embodiment, or may It only includes the grounding structure 300 in the second embodiment, and may also include the grounding structure 300 in the first embodiment and the grounding structure 300 in the second embodiment. The insulating housing 100 is provided with an installation slot 101 , the conductive terminal 200 and the grounding structure 300 are arranged in the installation slot 101 , the contact arm structure 3 is in electrical contact with the ground terminal in the conductive terminal 200 , the first support portion 1 and the The two support parts 2 are respectively in contact with the groove walls of the installation groove 101 .

[0092] Further, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com