A protective device for nuts with anodized layer in the process of flame brazing

A technology of flame brazing and protective devices, which is applied in the direction of auxiliary devices, welding equipment, metal processing equipment, etc., can solve the problems of inability to process design requirements of parts, difficult tooling design, and asbestos-contaminated weld seams, etc., to achieve welding protection and welding Quality problems, solving difficult processing problems, and preventing the effect of polluting weld seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

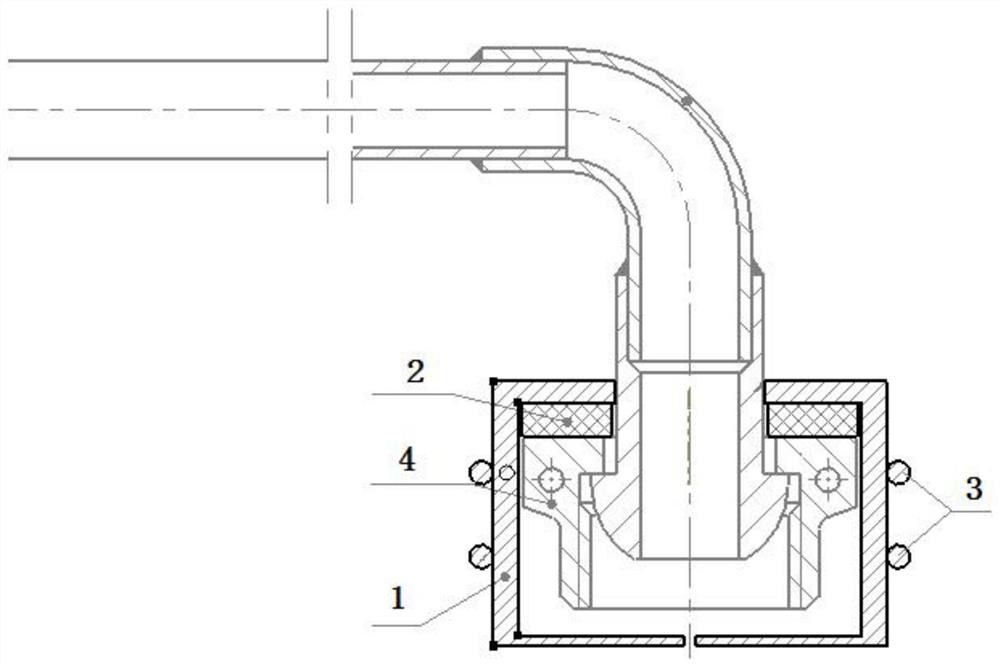

[0025] Such as figure 1 As shown, a protective device for nuts with anodized layers in the flame brazing process, including a shell 1 and a heat insulating liner 2;

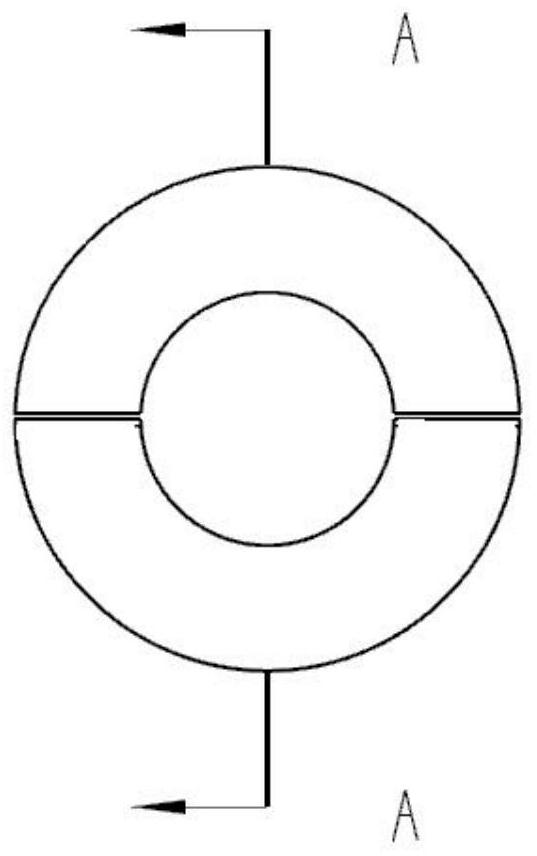

[0026] The shell 1 is two semi-cylindrical shells symmetrically distributed, the top surface is provided with a semicircular hole, and the outer surface is sprayed with high-temperature ceramics, and the whole nut 4 is wrapped in it during installation;

[0027] The heat insulating liner 2 is composed of two semicircular bodies, and is placed on the upper end surface of the nut 4 during installation to isolate the nut 4 from the shell 1 .

[0028] Further, the shell 1 is formed by symmetrically cutting the entire cylindrical shell, and after the cutting is completed, the surface is sprayed with high-temperature ceramics.

[0029] Further, when the casing 1 is cut a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com