Method and apparatus for processing coked waxy oil

A technology for coking wax oil and catalytic cracking device, which is applied in cracking, petroleum industry, catalytic cracking and other directions, can solve problems such as influence, and achieve the effects of increasing the amount of mixing, solving processing difficulties, and improving liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

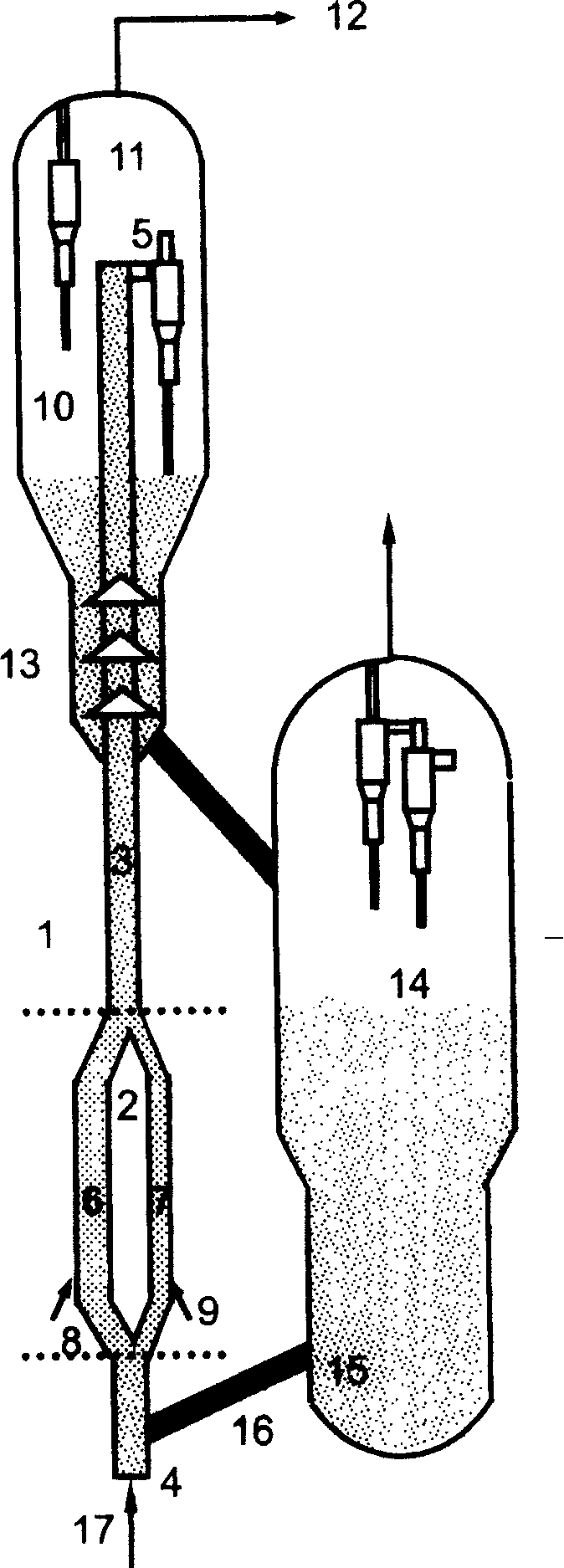

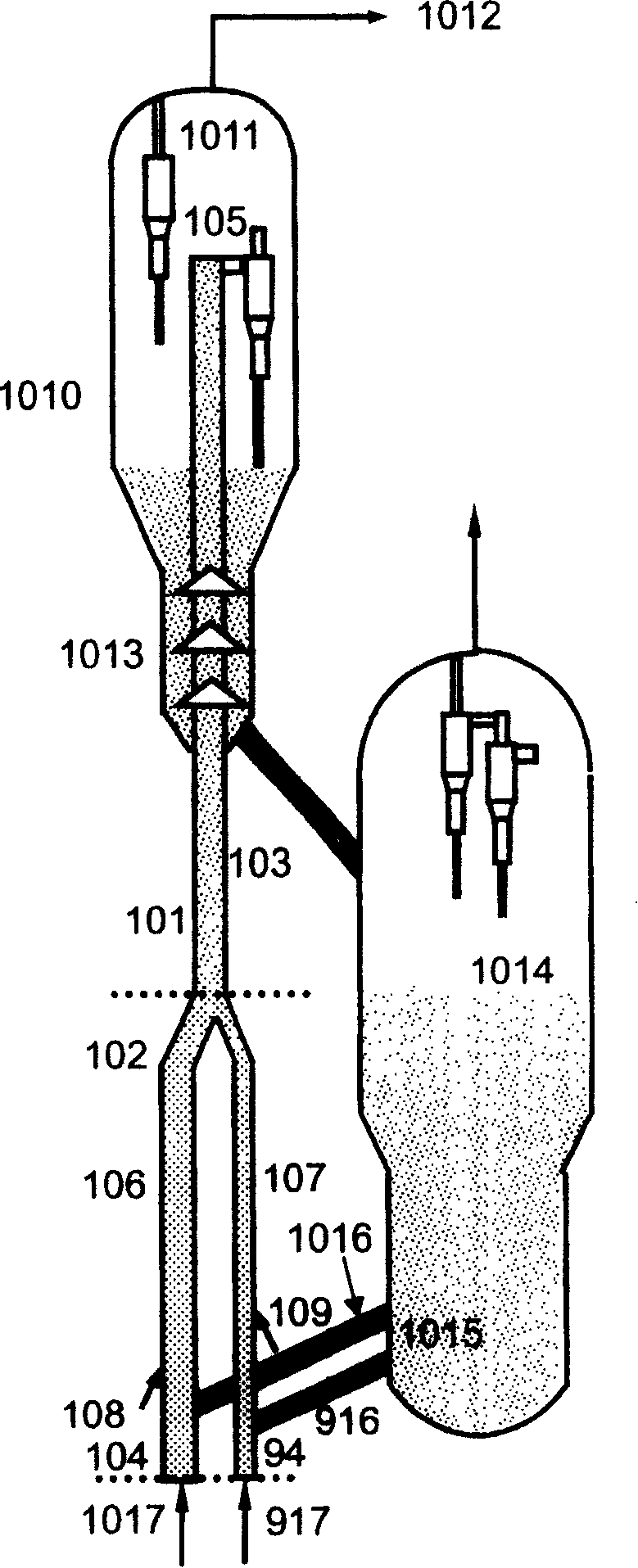

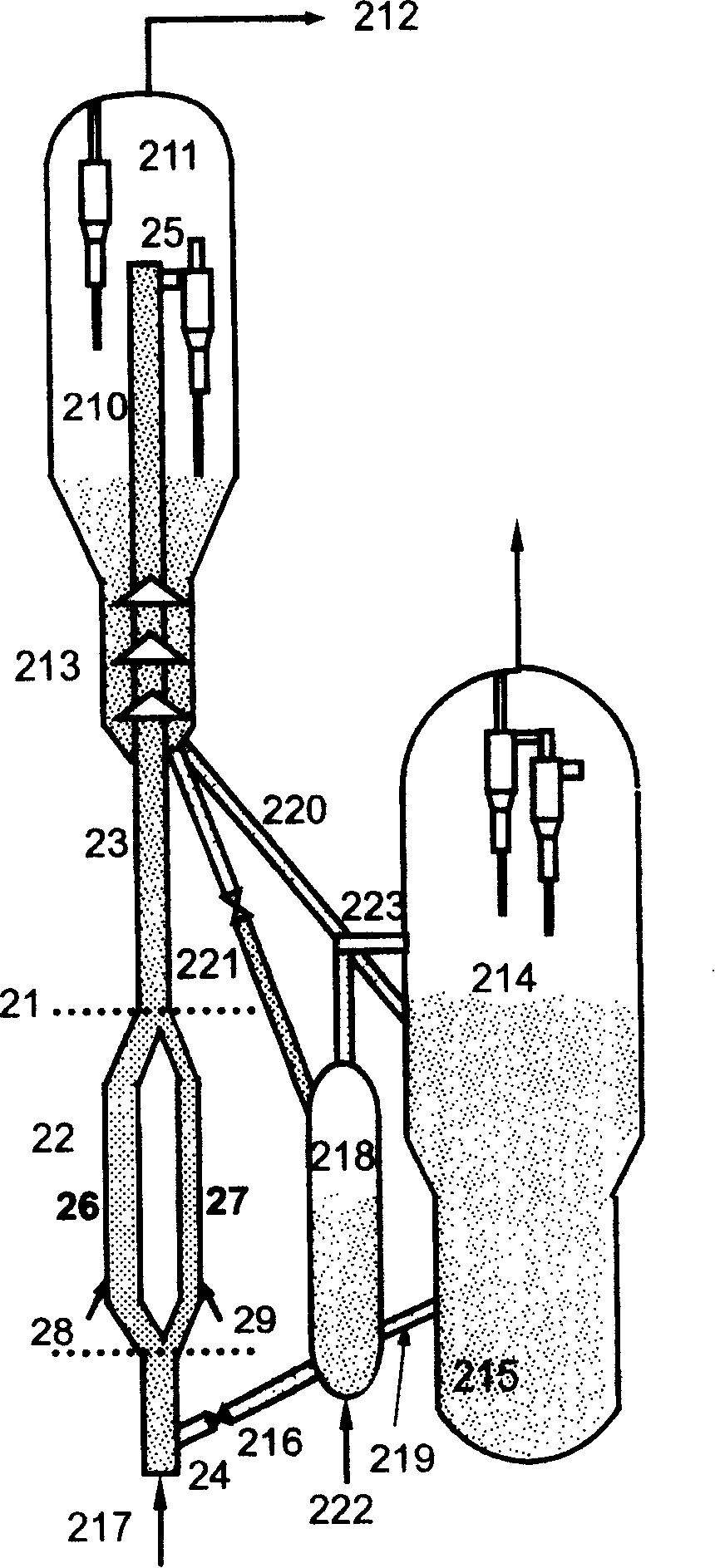

[0046] The technological process of embodiment 4 is that the conventional feedstock oil 58 with a preheating temperature of 100 to 300 ° C, preferably 150 to 250 ° C, enters the reaction zone 56 from the bottom of the reaction zone 56 through feeding nozzles symmetrically and evenly distributed in the circumferential direction, and comes from the regenerator. 64 The temperature raised by the pre-lifting steam 67 is 600-750°C, preferably 650-700°C, and the reaction temperature of the regenerant 65 is 460-550°C, preferably 480-510°C, and the ratio of agent to oil is 4-12, preferably 6- 9. The catalyst activity is 50-70, preferably 58-65, the reaction time is 2.0-3.5s, preferably 2.5-3.0s, and the reaction pressure is 0.1-0.4MPa for contact, gasification, mixing and reaction, oil, gas, water vapor It enters the upper reaction zone 53 of the riser reactor 51 together with the catalyst. Two regenerant inclined pipes 69 and 76 are arranged at the bottom of the regenerator 64. The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com