One-pot liquefaction process of biomass

A biomass and solid biomass technology, applied in the field of biomass one-pot liquefaction process, can solve problems such as insufficient reaction and coke polycondensation, and achieve the effects of avoiding coke formation, promoting hydrolysis, and improving hydrogenation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment provides a kind of preparation method of the second catalyst, comprising the following steps:

[0044] S1. After acidification or basification of dry distillation biomass charcoal, the second biomass charcoal carrier is obtained; specifically: H in the acidic medium of the acidification treatment + The concentration of the substance is 5mol / L; the volume ratio of the dry distillation biochar to the acidic medium is 1:15, the acidification temperature is 80°C, and the acidification time is 10h; - The concentration of the substance is 0.5mol / L; the volume ratio of the carbonized biomass charcoal to the alkaline medium is 1:5, the alkalization temperature is 30°C, and the alkalization time is 10h.

[0045] S2. Vibrating and / or plane grinding and / or ball milling the second active component and the second biochar carrier to obtain a second catalyst with a particle size of 100 μm-200 μm.

[0046] The second active component is the oxides of Mo and W, a...

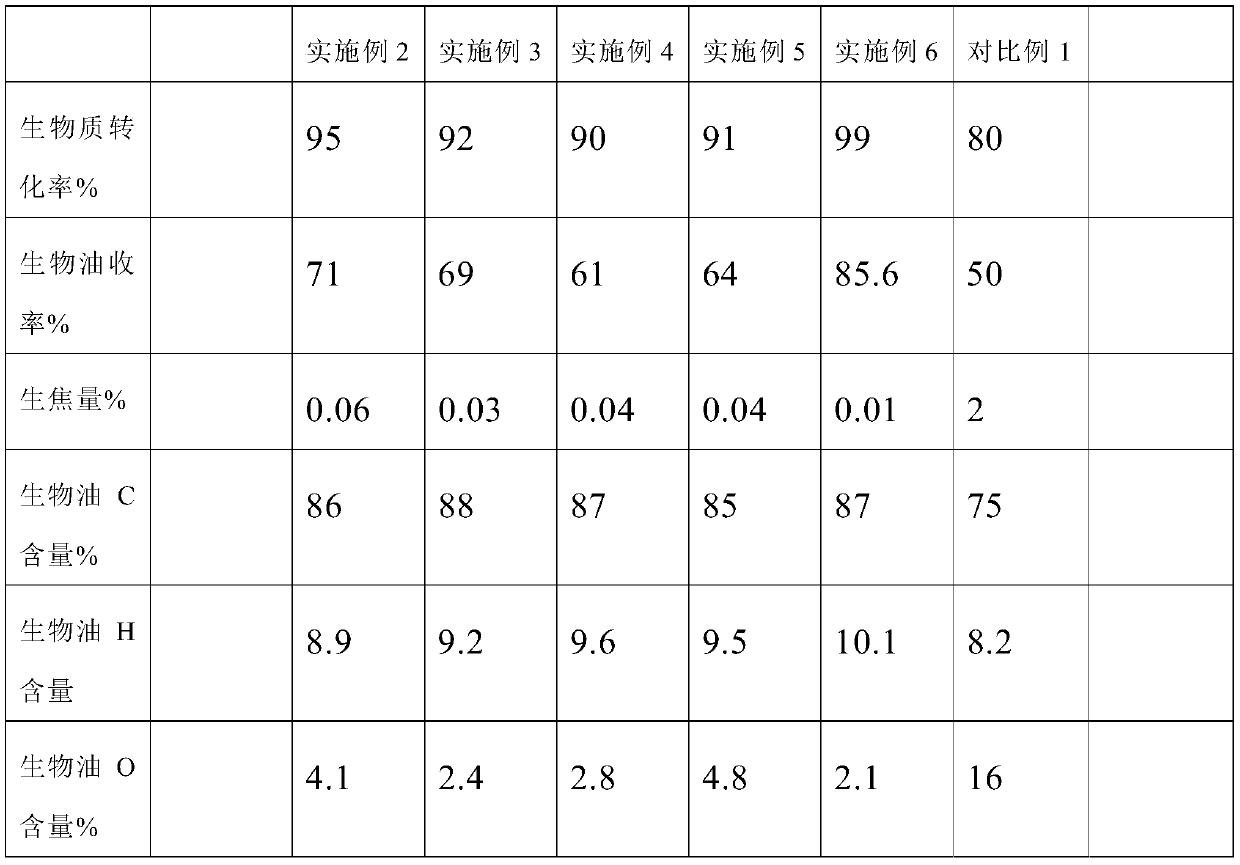

Embodiment 2

[0048] The one-pot liquefaction process of biomass provided in this embodiment comprises the following steps:

[0049] (1) sending corn stalks into a dryer to dry until the water content is 3wt%, and then pulverizing them in a pulverizer to a particle size of 1-50 μm, and then obtaining straw particles after deashing;

[0050] (2) Mix the amorphous alumina (with a particle size of 5 μm-50 μm) loaded with Mo oxide and Co oxide with the straw particles and sulfur in step (1) in a mass ratio of 5:100:0.3 A mixture is obtained, which is added to medium-low temperature coal tar to form a slurry containing 10 wt% of biomass;

[0051] (3) Inject hydrogen at 60°C and 13MPa into the slurry for the first time until the volume ratio of high-pressure hydrogen to slurry is 50:1, then raise the temperature of the slurry to 200°C in the heat exchanger, and then inject the second Inject hydrogen at 200°C and 13MPa once, and control the volume ratio of hydrogen and slurry injected twice to re...

Embodiment 3

[0053] The one-pot liquefaction process of biomass provided in this embodiment comprises the following steps:

[0054] (1) sending the reed into a drier and drying it until the water content is 5wt%, then pulverizing it in a pulverizer to a particle size of 20-1000 μm, and then obtaining reed particles after deashing;

[0055] (2) Biomass charcoal (with a particle size of 100 μm-150 μm) loaded with W oxide and Ni oxide, iron oxyhydroxide, reed particles and sulfur in step (1) are in a mass ratio of 2:2:100: The ratio of 0.4 is mixed to obtain a mixture, and the mixture is added to vegetable oil to form a slurry containing 30wt% of biomass;

[0056] (3) Inject hydrogen at 70°C and 20MPa into the slurry for the first time until the volume ratio of high-pressure hydrogen to slurry is 100:1, then raise the temperature of the slurry to 250°C in the heat exchanger, and then inject the second Inject hydrogen gas at 250°C and 20MPa once, and control the volume ratio of the hydrogen g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com