Patents

Literature

44results about How to "Fully cracked" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength high-ductility low-density steel plate of 1200 MPa grade and manufacturing method thereof

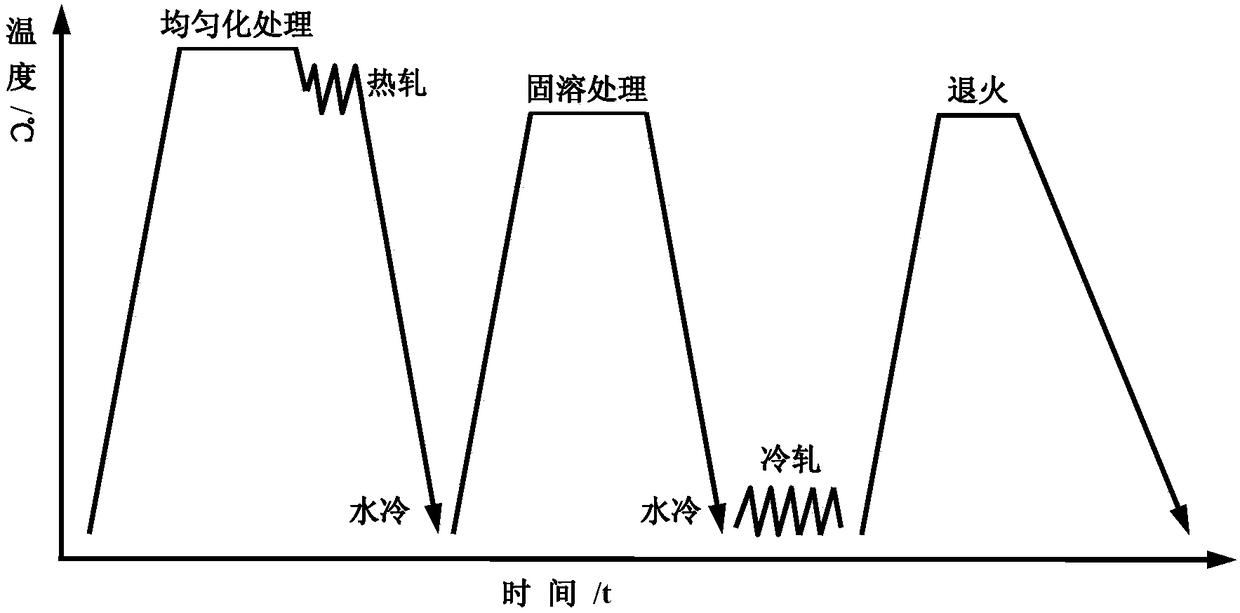

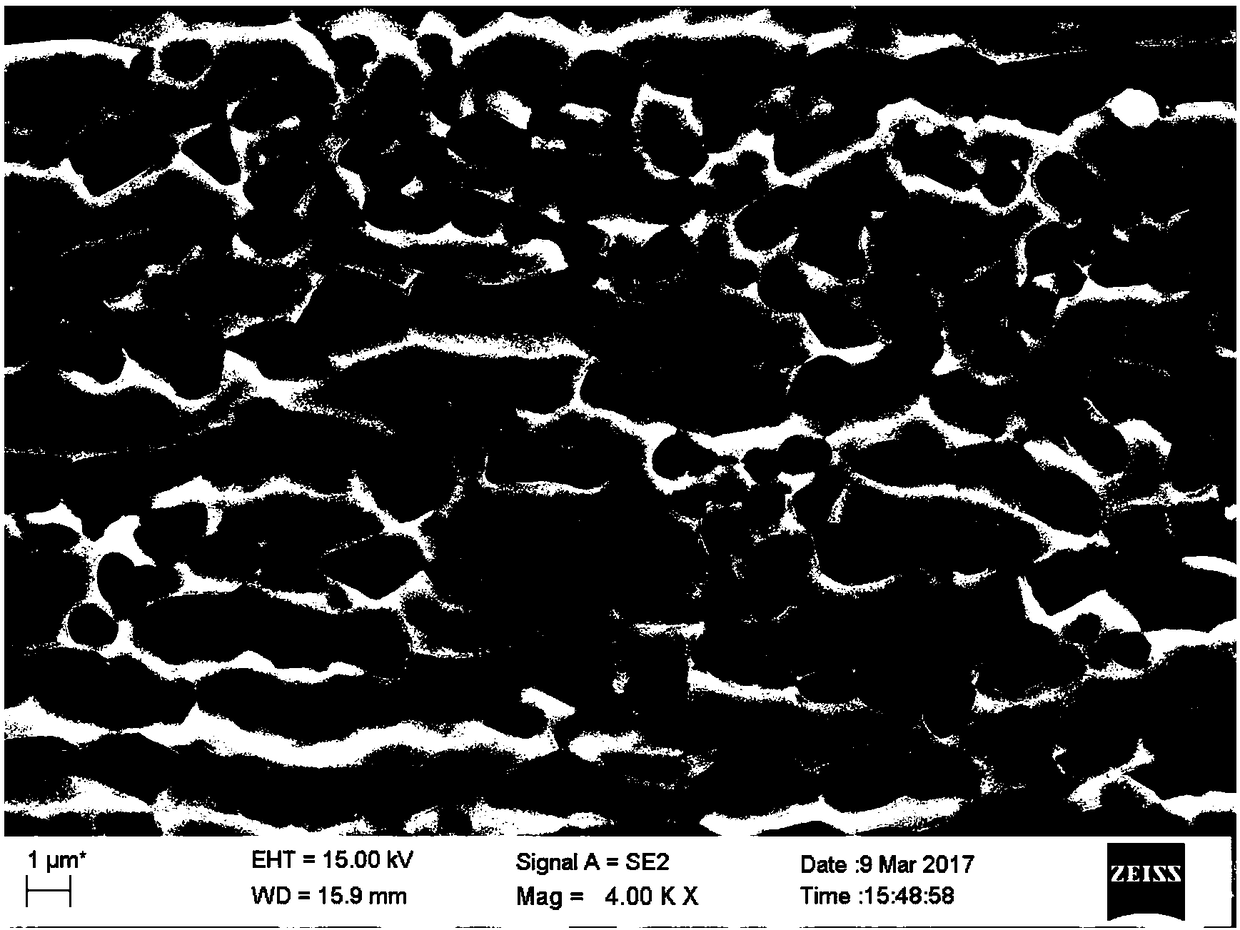

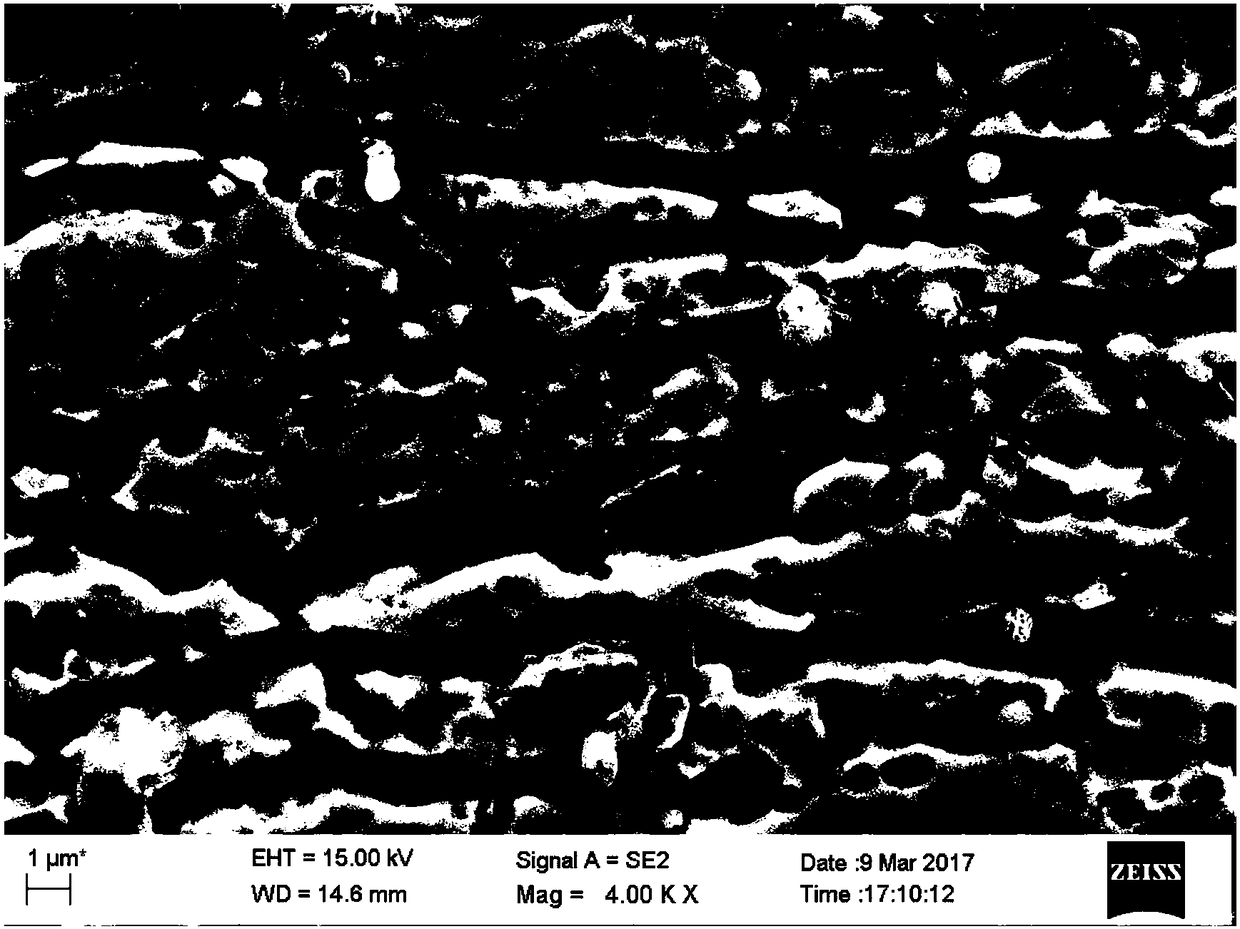

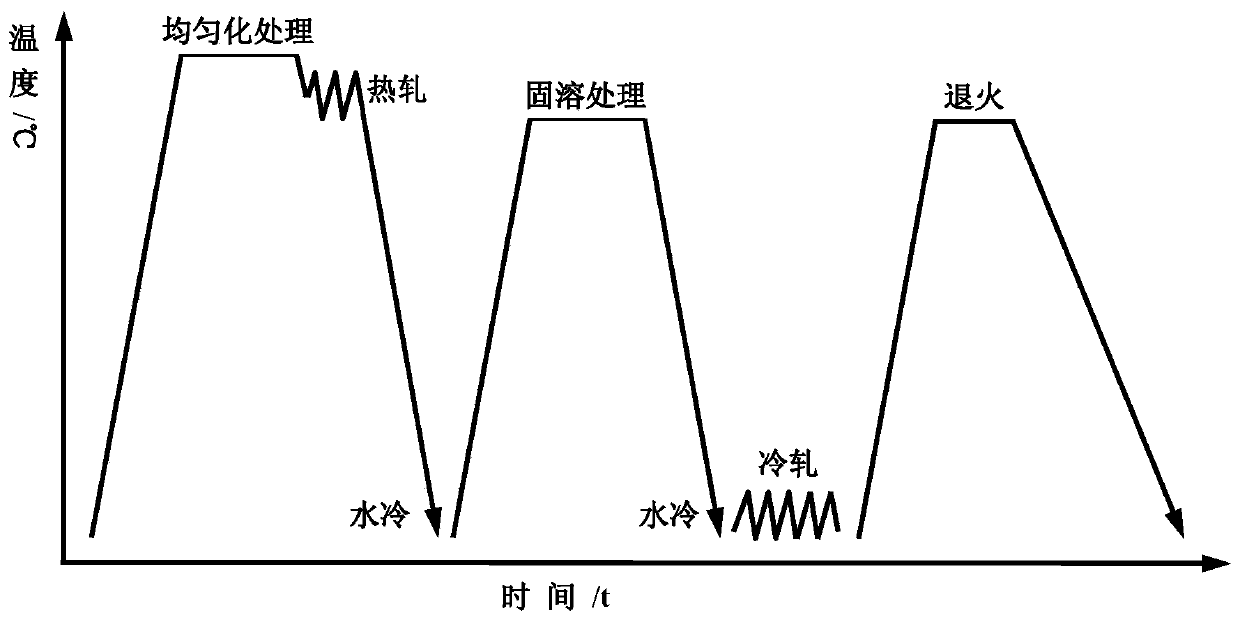

The invention relates to a high-strength high-ductility low-density steel plate of the 1200 MPa grade and a manufacturing method thereof. The high-strength high-ductility low-density steel plate is prepared from the following components according to mass percent: 0.7 to 1% of C, 13 to 20% of Mn, 8 to 11% of Al, 1 to 4% of Ni, less than 0.1% of Si, less than 0.01% of S, less than 0.01% of P, 0 to 0.1% of Ti, 0 to 0.1% of Nb and 0 to 0.15% of V; the tensile strength is 1200 to 1300 MPa, the elongation is 30 to 40%, and the density is 6.5 to 7 g / cm<3>. The manufacturing method comprises the following steps of (1) smelting molten steel according to the components, and pouring; (2) heating to 1100 to 1200 DEG C, performing hot rolling after heat preservation, and performing water cooling to theroom temperature after hot rolling is finished; (3) heating to 900 to 1100 DEG C, and performing water cooling after heat preservation; (4) performing cold rolling after pickling; and (5) heating to800 to 1000 DEG C, and performing air cooling after heat preservation. The low-density steel plate has high strength and high ductility.

Owner:NORTHEASTERN UNIV

1200mpa grade high-strength high-plasticity low-density steel plate and manufacturing method thereof

A 1200MPa grade high-strength, high-plasticity, low-density steel plate and its manufacturing method. The composition contains C 0.7~1%, Mn 13~20%, Al 8~11%, Ni 1~4%, Si<0.1% in mass percentage. S<0.01%, P<0.01%, Ti 0~0.1%, Nb 0~0.1%, V 0~0.15%, tensile strength is 1200~1300MPa, elongation is 30~40%, density is 6.5~7g / cm 3 ; The manufacturing method is: (1) smelting molten steel according to the above composition and casting; (2) heating to 1100~1200℃ and then hot rolling, and then water cooling to room temperature after the hot rolling is completed; (3) heating to 900~1100℃ after insulation Water cooling; (4) pickling and cold rolling; (5) heating to 800~1000℃ and then air cooling. The low-density steel plate of the present invention can obtain high strength while still ensuring good plasticity.

Owner:NORTHEASTERN UNIV LIAONING

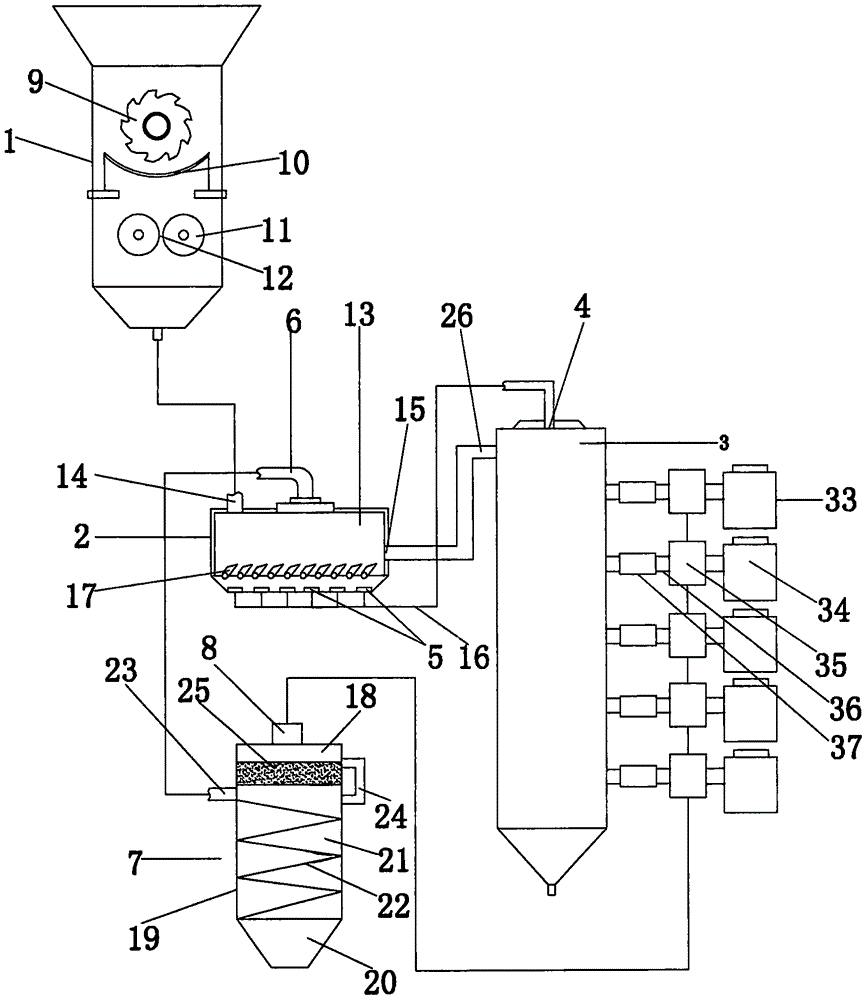

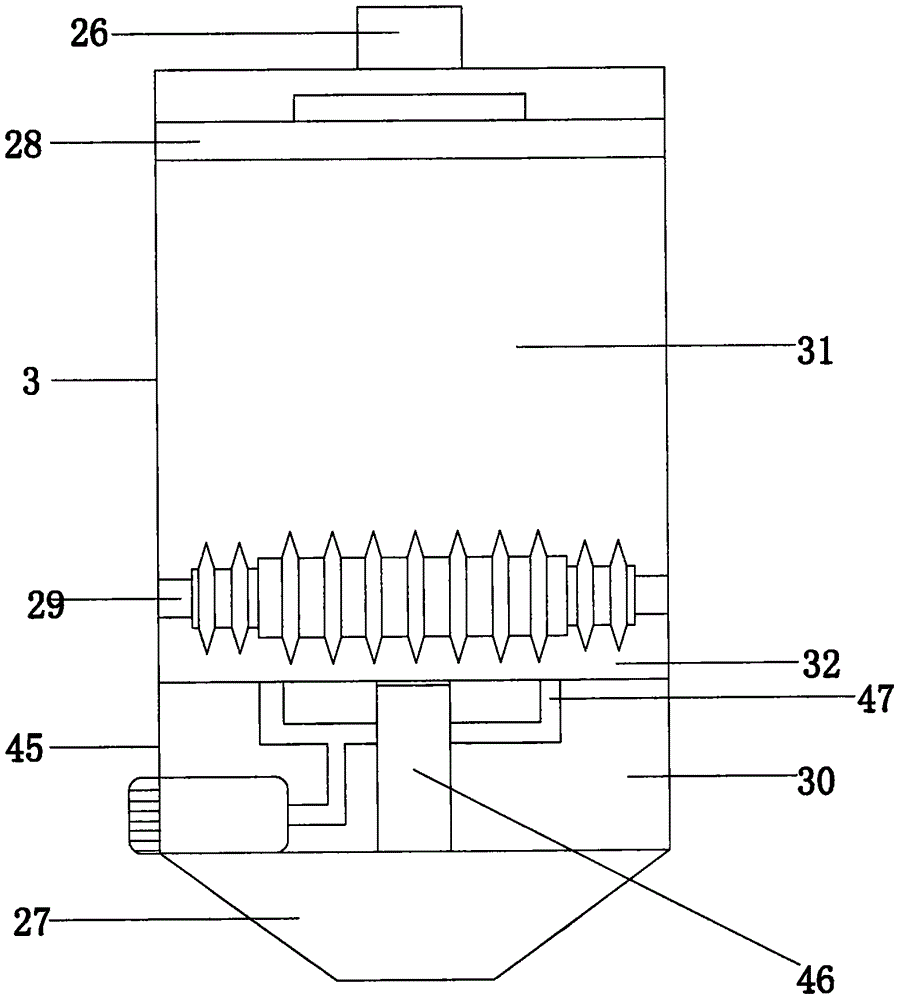

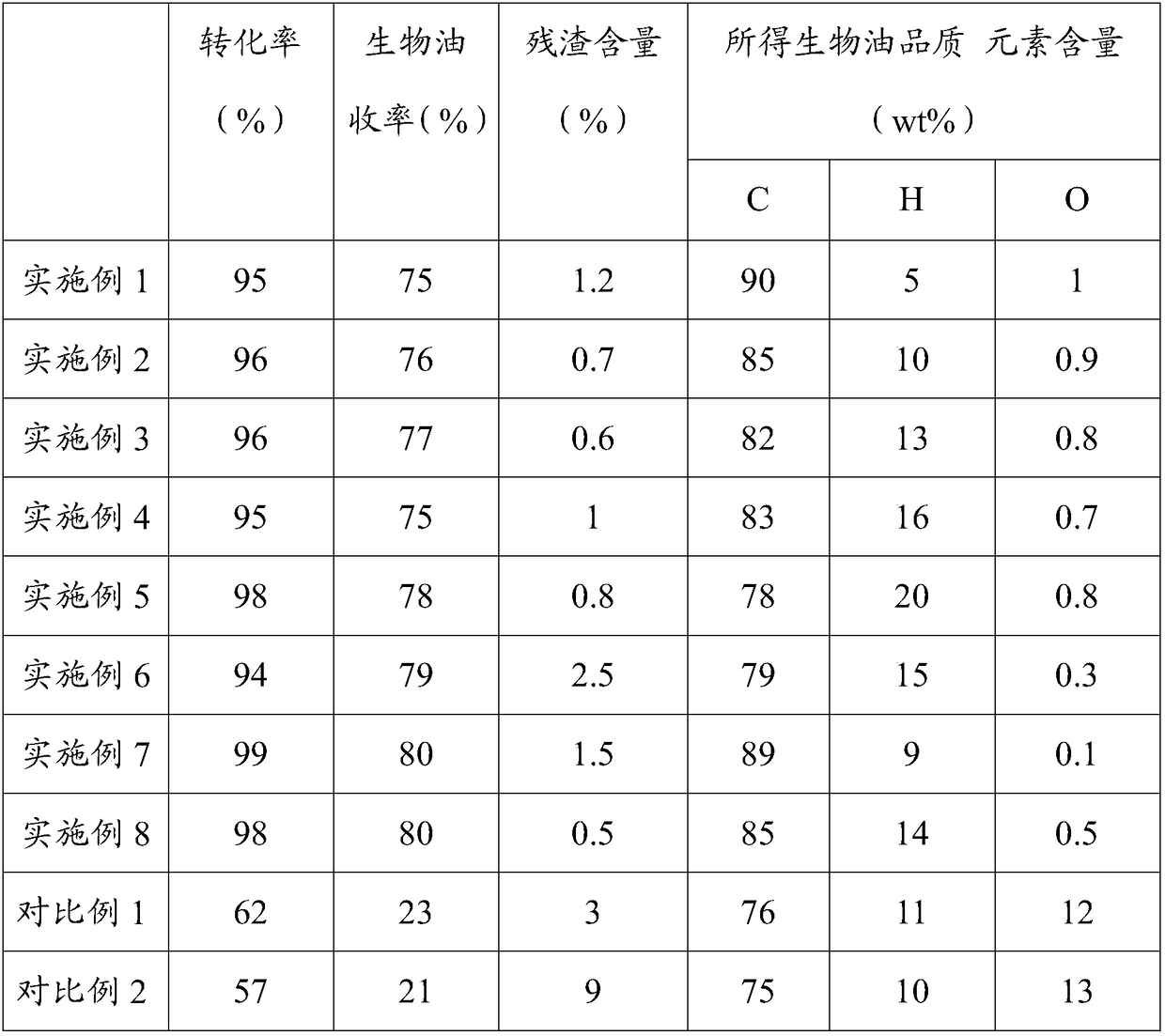

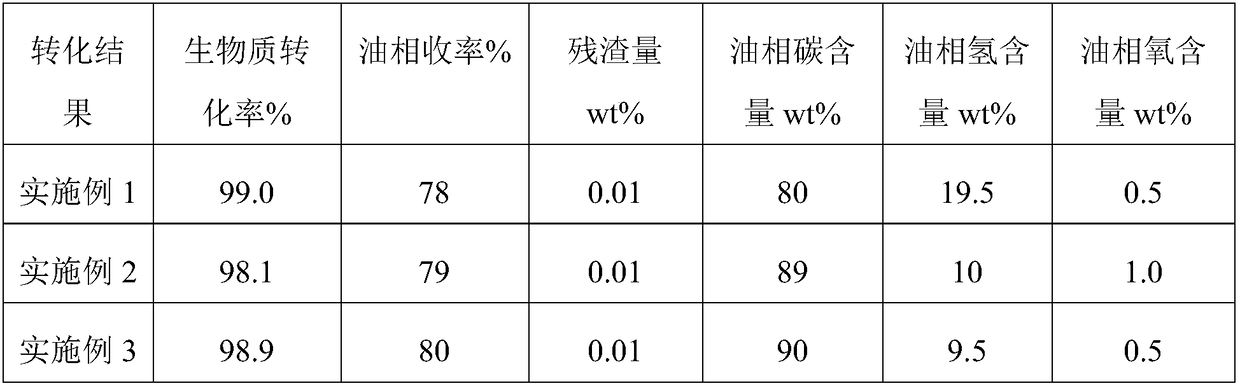

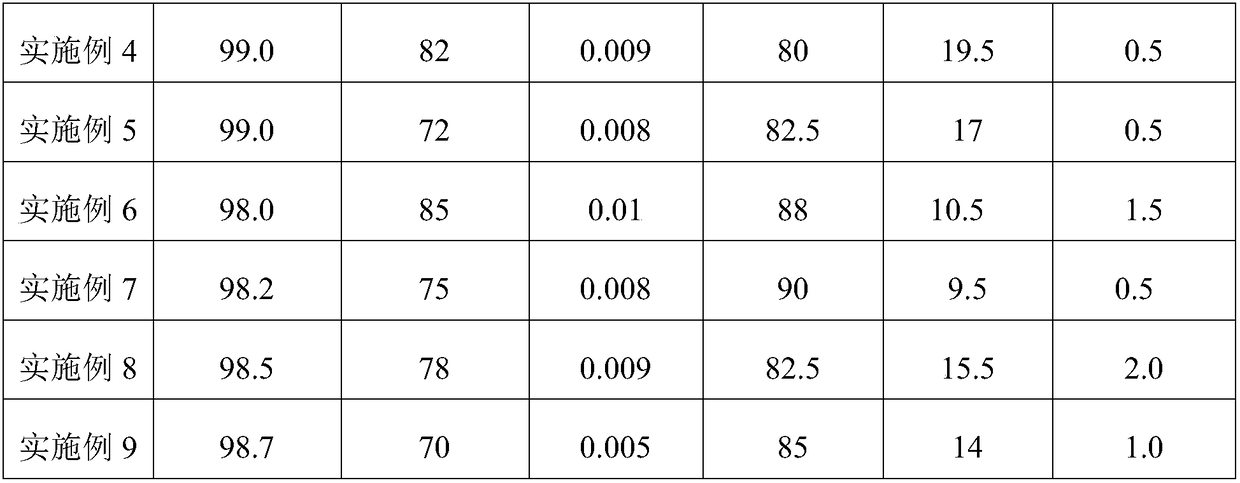

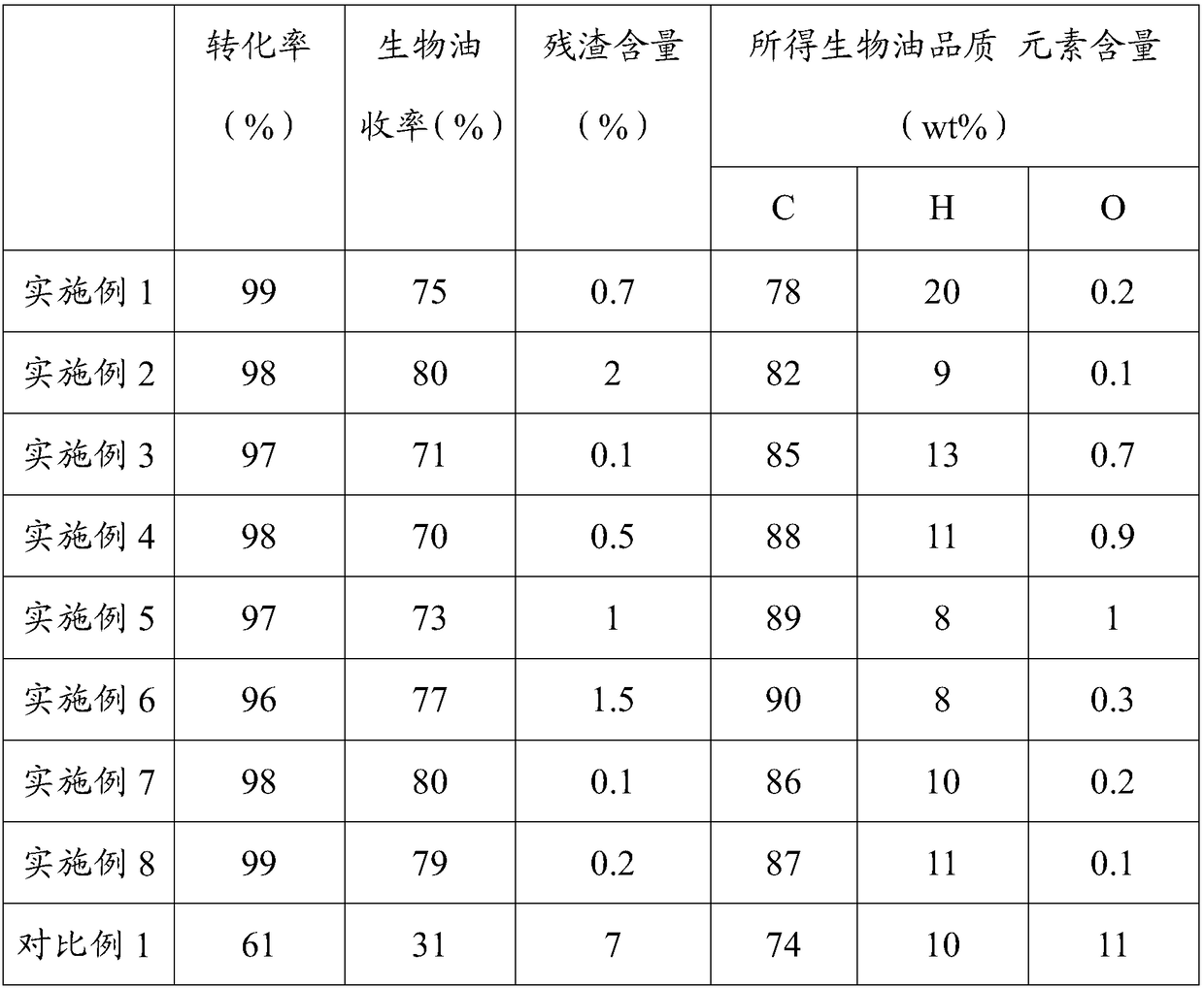

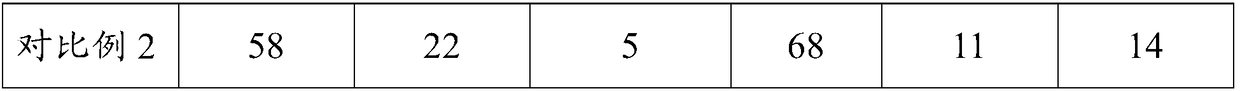

Coal and biomass one-pot liquification process

ActiveCN108219819ARealize mixing and liquefactionImprove liquidityLiquid hydrocarbon mixture productionBio-feedstockKeroseneEngineering

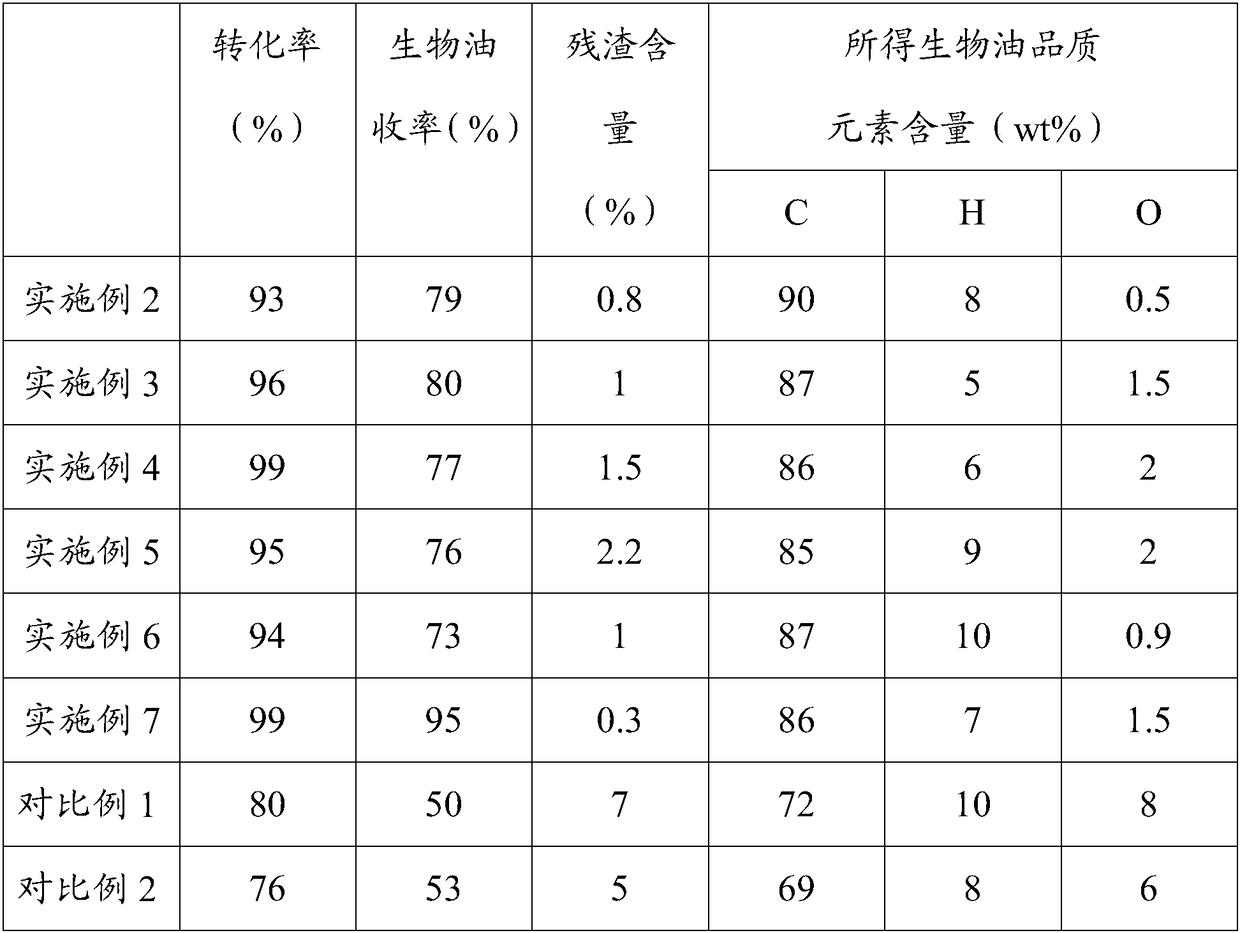

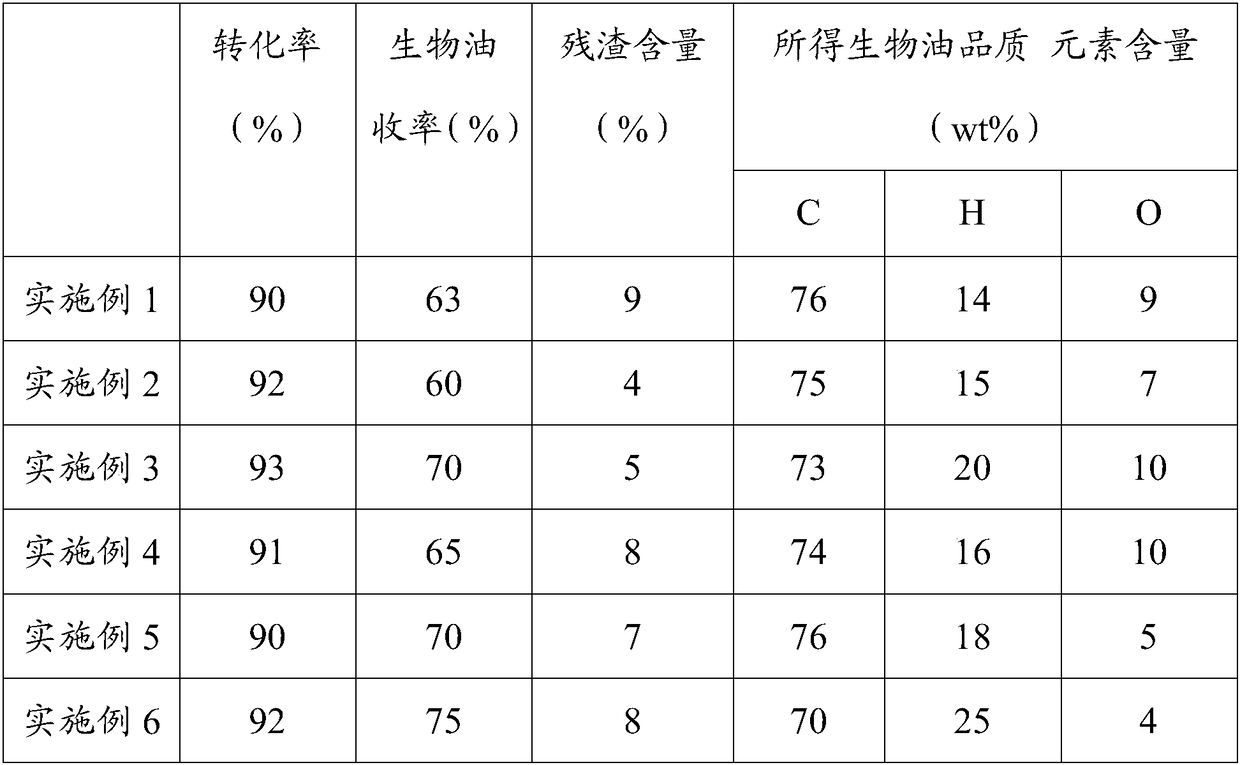

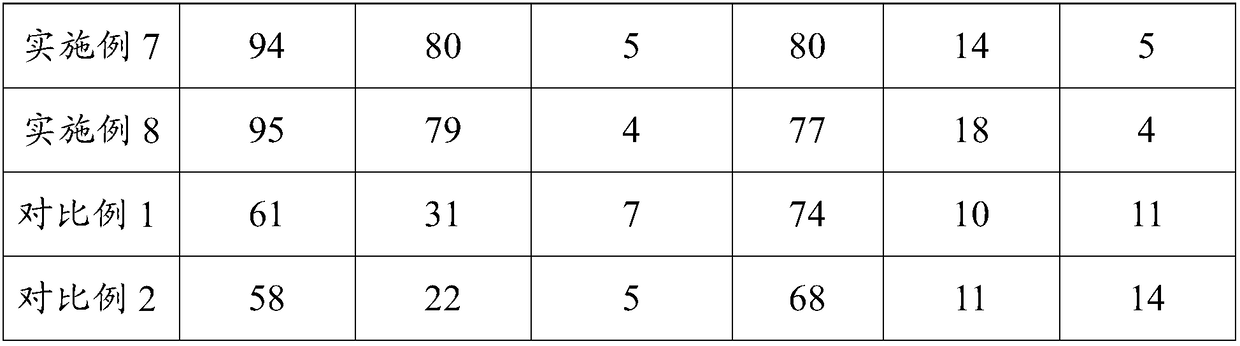

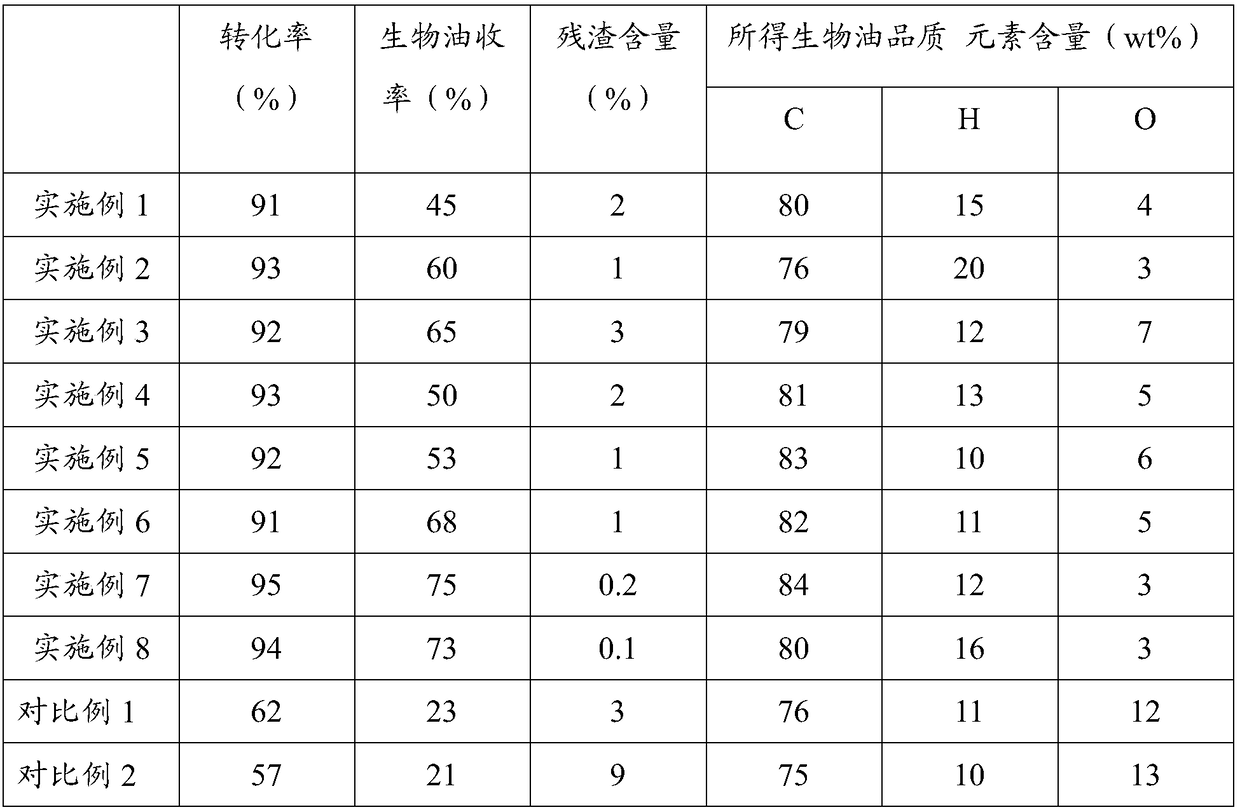

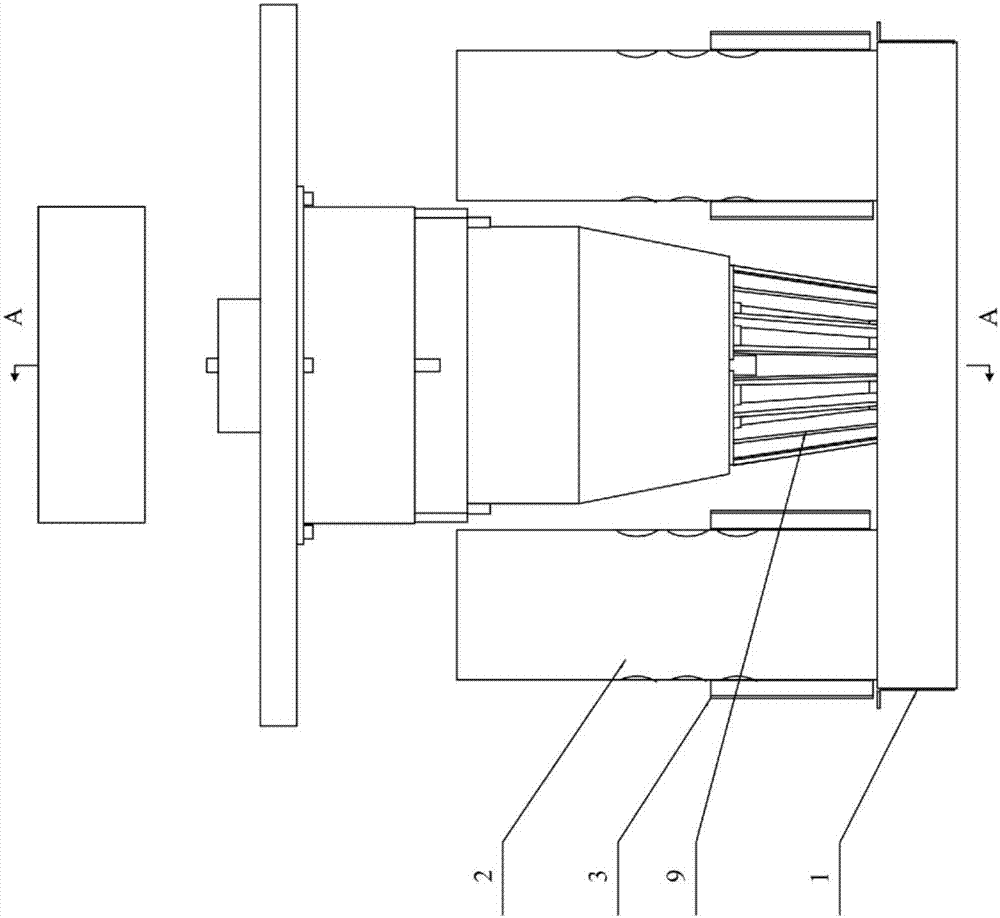

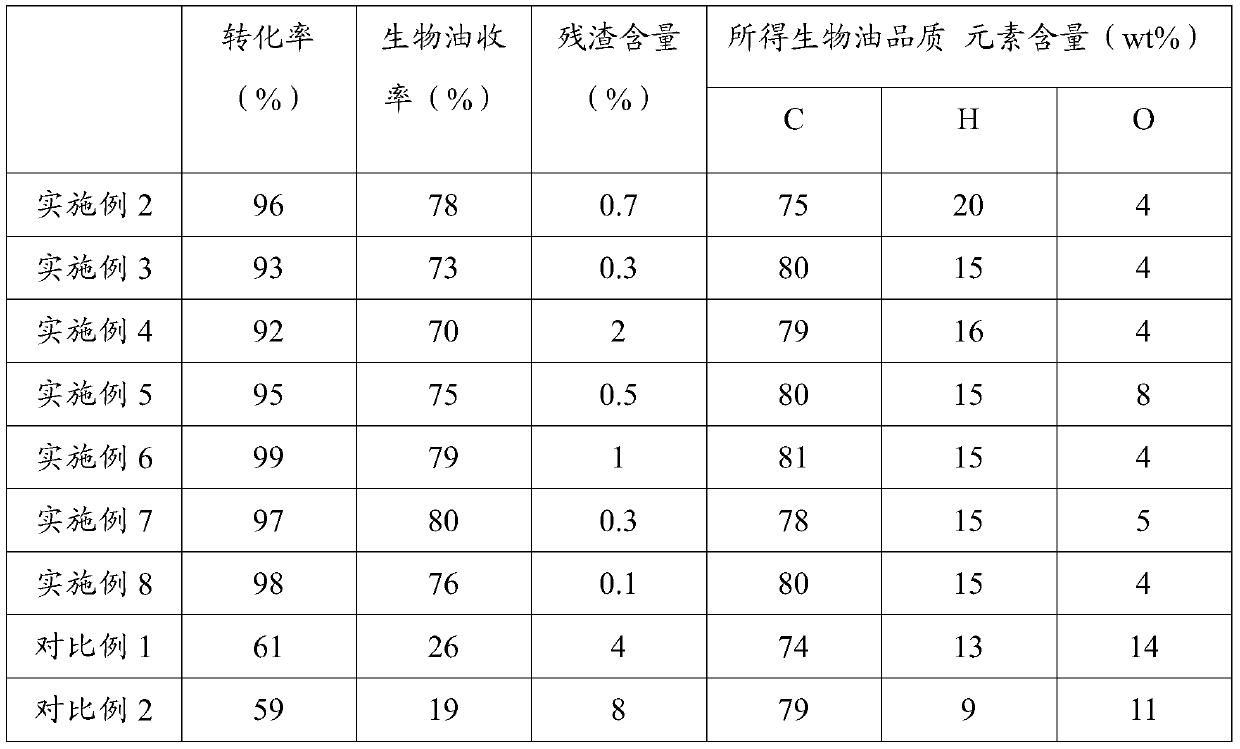

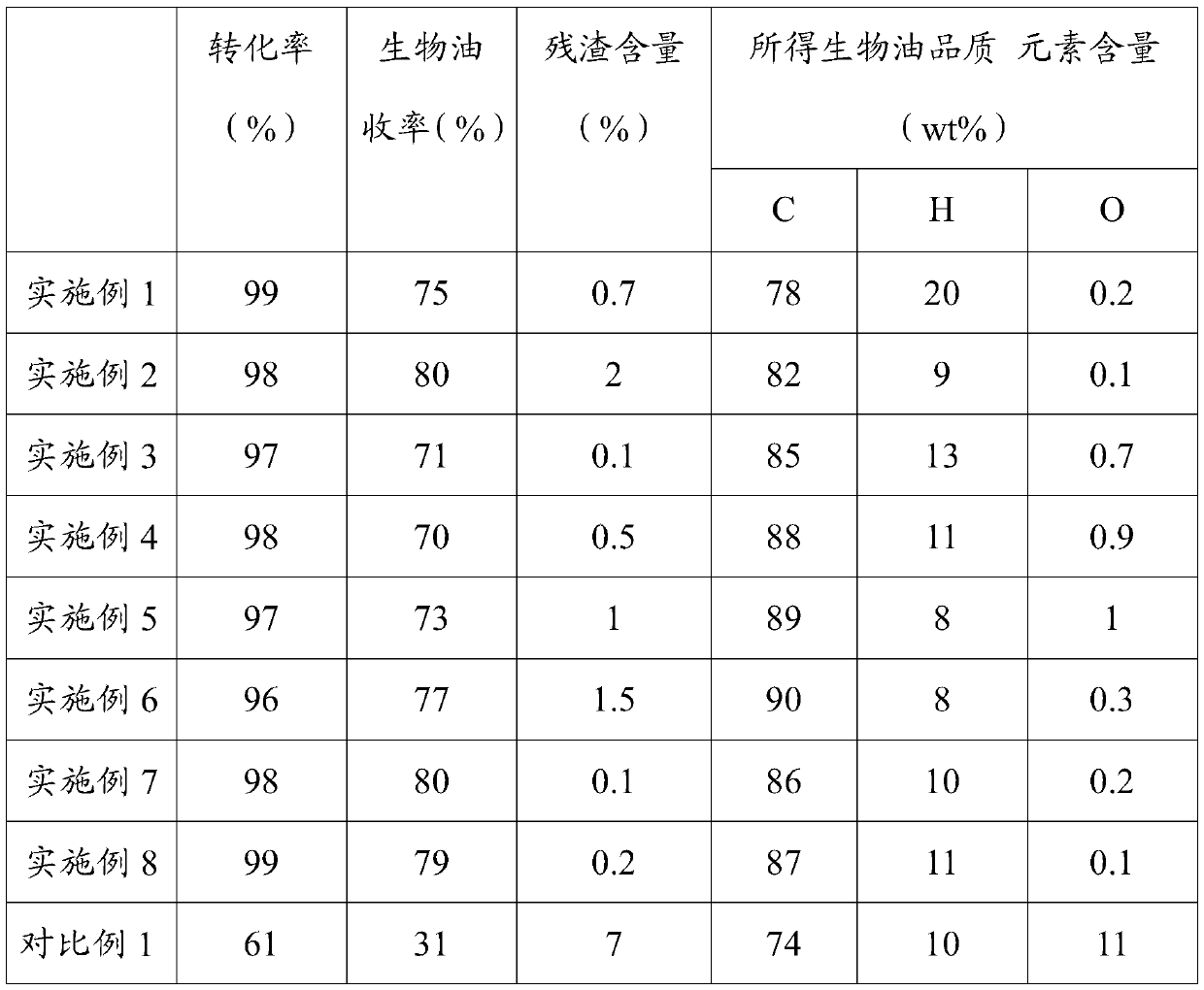

The invention relates to the technical field of a clean energy source, in particular to a coal and biomass mixing process. The mixing liquification of coal, biomass and oil is creatively realized forthe first time. Firstly, coal and biomass raw materials are subjected to treatment of crushing, compression and secondary crushing; then, slurry is prepared; biomass coal oil slurry with high solid content and capability of being stably conveyed by a pump is successful obtained, so that high-viscosity waste oil which cannot be used as a coal and biomass liquification solvent in the prior art can also be utilized. Hydrogen gas is introduced into the biomass coal oil slurry for reaction, so that coal and biomass are liquified at high pressure and high temperature; then, cracking and hydrogenation reaction are further performed, so that the conversion of coal and biomass into biological oil is realized. The process provided by the invention has the advantages that the coal and biomass conversion rate can reach 90 to 99 percent; the yield of the biological oil can reach 60 to 80 percent; the residue quantity is not higher than 2.5 weight percent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Garbage cracking furnace system

InactiveCN105757676AOutstanding and Beneficial Technical EffectsAvoid pollutionIncinerator apparatusCold airCold blast

The invention provides a garbage cracking furnace system and belongs to the technical field of a garbage cracking furnace.The system solves the problems that an existing garbage cracking furnace causes environment pollution, and the cracking effect is not good.The garbage cracking furnace system comprises a garbage smashing and dehydrating mechanism, a garbage pre-airing mechanism and a garbage cracking furnace which are sequentially connected.A high-temperature waste gas outlet of the garbage cracking furnace is connected with a hot air inlet of the garbage pre-airing mechanism through a pipeline, and accordingly pre-airing treatment is conducted on garbage by means of high-temperature waste gas.A cold air outlet of the garbage pre-airing mechanism is connected to a purification condenser, and a purified air outlet of the purification condenser is connected to the garbage cracking furnace so that the purified air can return into the garbage cracking furnace for use.The system has the advantages of being capable of avoiding environment pollution, according with the concept of environment friendliness, improving work efficiency of the garbage cracking furnace, being high in carbon recycling efficiency and the like.

Owner:赵君华

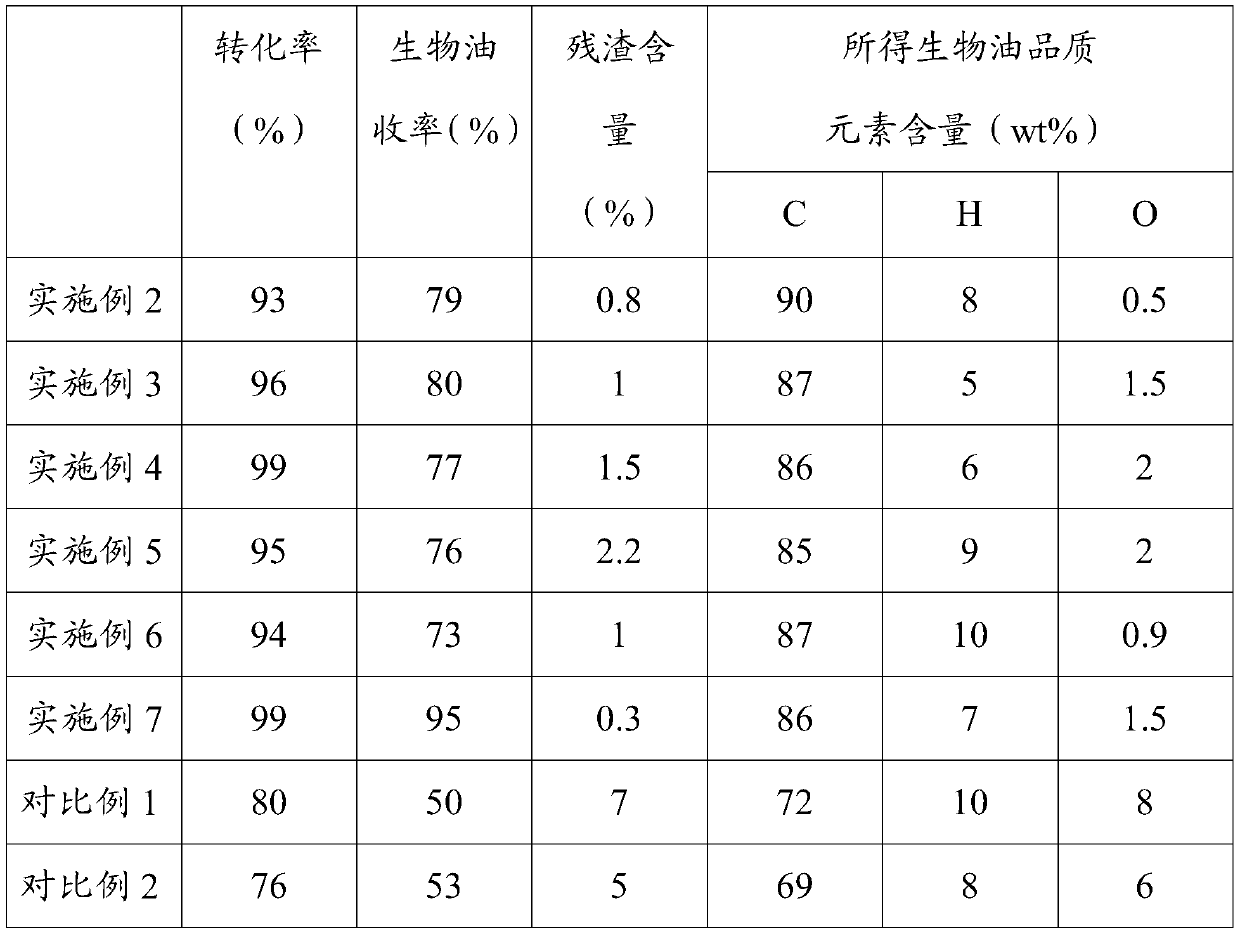

Multi-grade liquefying technology of coal and biomass

ActiveCN108285808ARealize mixing and liquefactionIncrease contactBiofuelsLiquid hydrocarbon mixture productionSolventBiomass

The invention relates to the technical field of clean energy, and specifically provides a multi-grade liquefying technology of coal and biomass. The technology is characterized in that the coal and the biomass raw materials are processed by crushing, compressing and crushing again, then the sizing is prepared, so that biomass diesel oil which is high in solid content and can be stably conveyed through a pump can be obtained; high-viscosity waste oil which cannot be used as a coal and biomass liquefying solvent in the prior art can be utilized. According to the technology, coal and biomass canbe liquefied under high pressure and high temperature in the existence of proper volume of water; the liquefying product is sequentially subjected to primary cracking, hydrogenation reaction and deepcracking and hydrogenation reaction under the effects of resisting hydrogen and a first catalyst and a second catalyst, so that the coal and the biomass can be converted into biomass oil, and the biomass oil can be refined; the conversion rate of the biomass and the coal is up to 95-99%; the yield of the biomass oil is up to 70-80%; and moreover, the residue content is less than 2.5%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

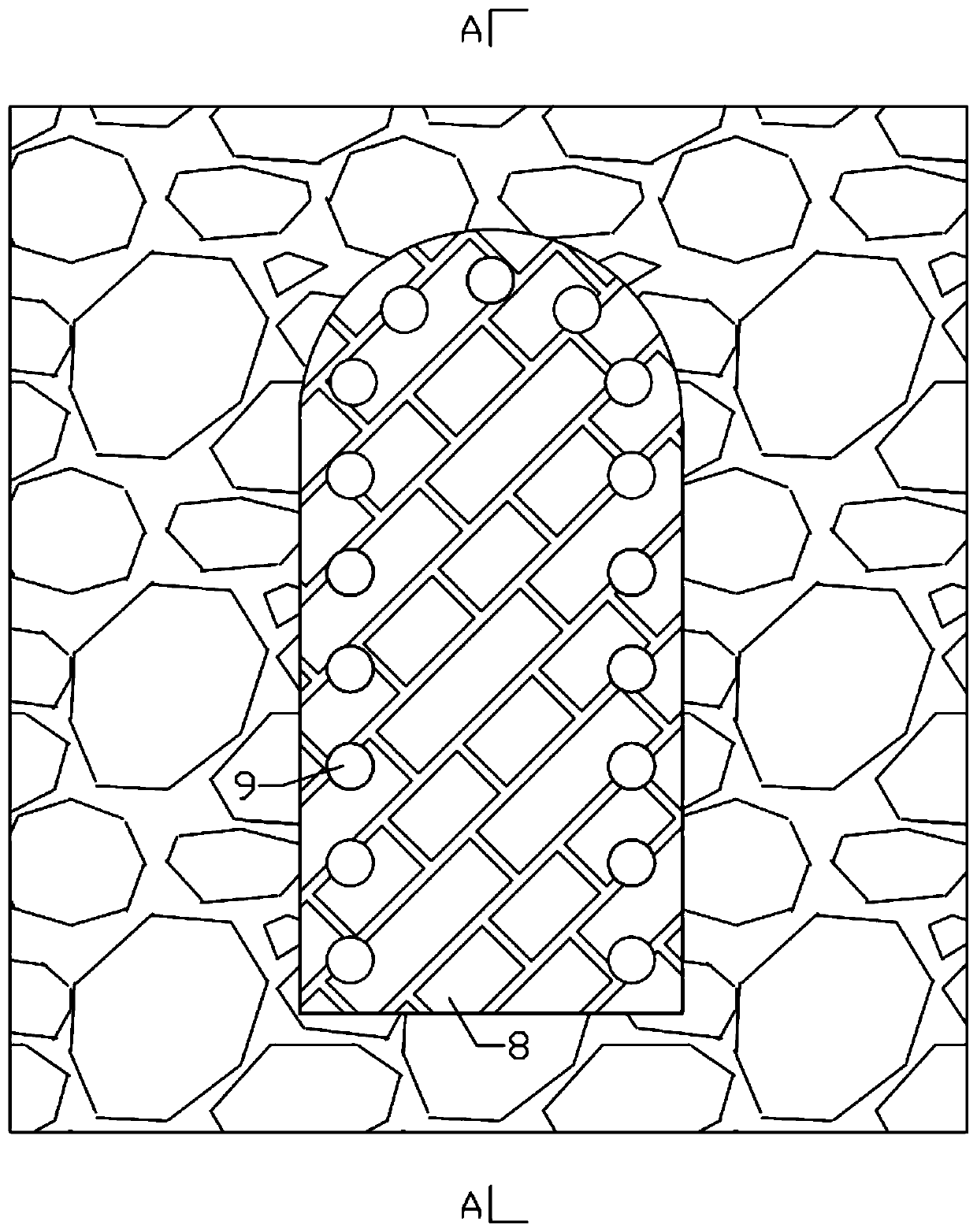

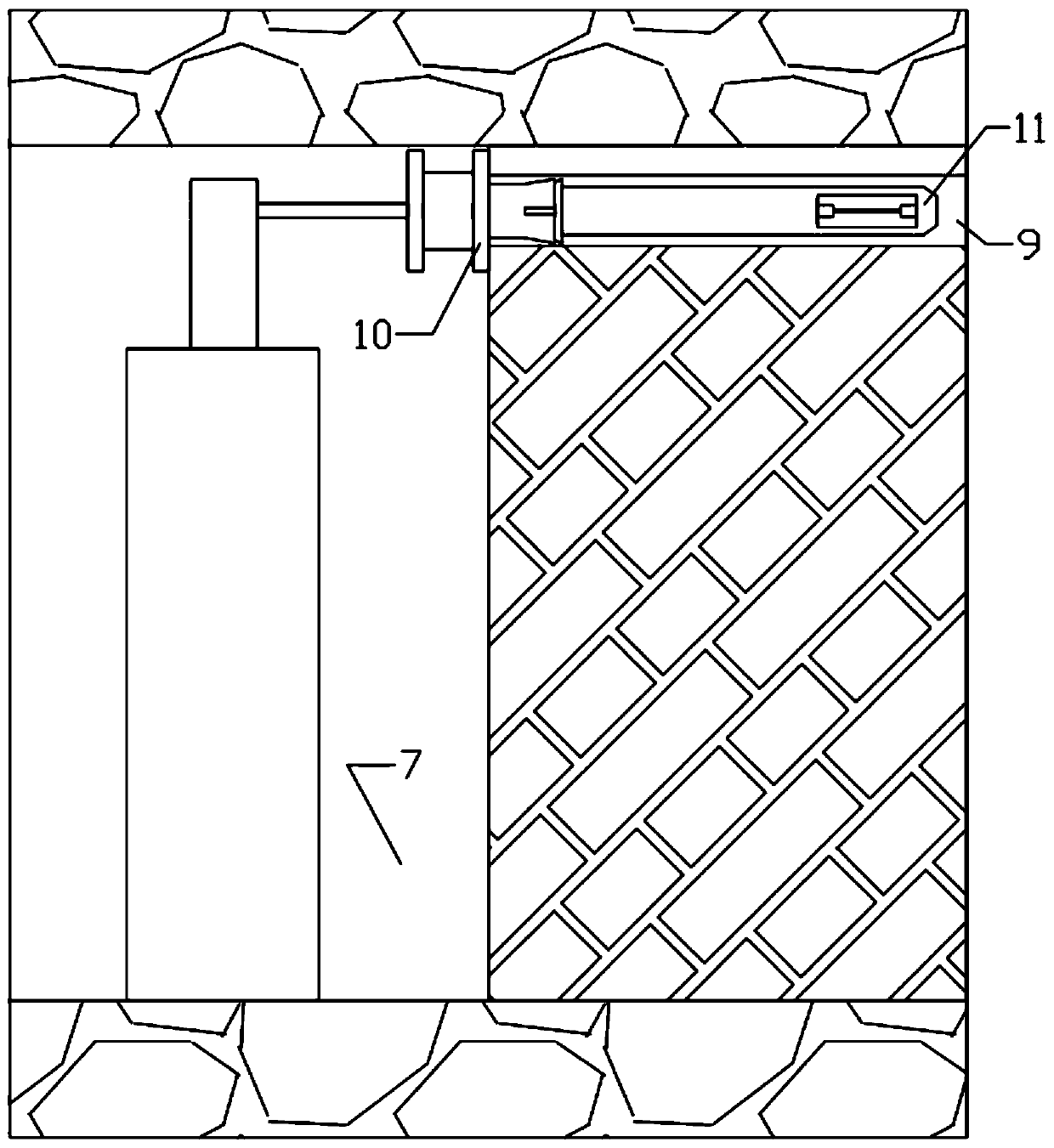

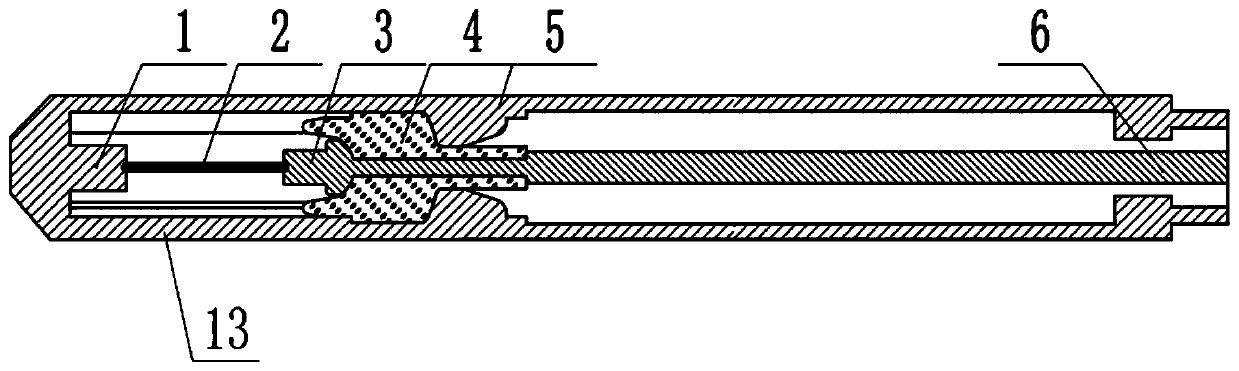

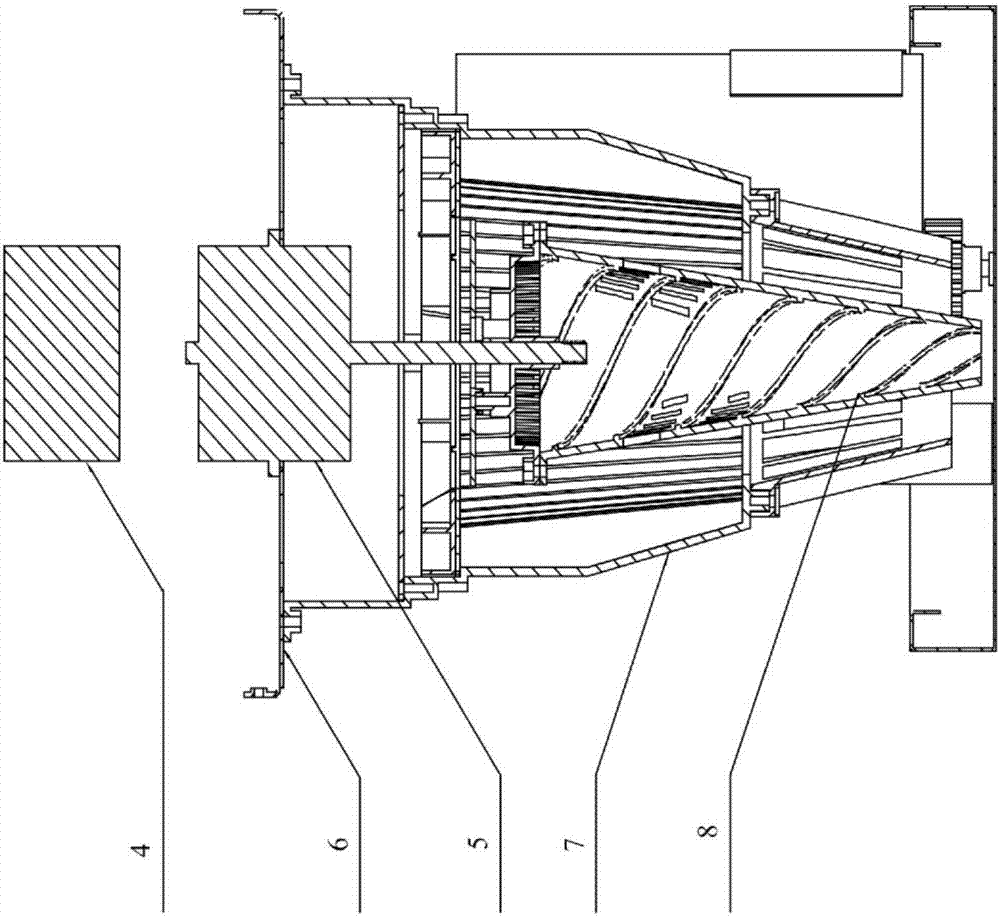

Rock pre-splitting method for mine rock roadway driving face

ActiveCN111472780AImprove conversion efficiencyImproves the effect of cracking rocksDisloding machinesUnderground miningConvertersEnergy converter

The invention relates to a rock pre-splitting method for a mine rock roadway driving working face, and aims to solve the problems of high risk and poor environmental protection property when explosives are used for pre-splitting rocks at present. The rock presplitting method for the mine rock roadway driving face comprises the following steps of S1, setting drilling positions and number of rocks in a rock roadway, drilling boreholes in the rocks, wherein the boreholes are formed in two sides and the top of the rocks in the roadway, and axes of the boreholes are parallel to an extending direction of the rock roadway; S2, installing an orifice device in each borehole, and filling the boreholes with water; S3, connecting an energy converter with a pulse power driving source, and placing the energy converter in the borehole; and S4, starting a pulse power driving source to discharge electricity to the energy converter, wherein the rock is cracked by shock waves generated by the energy converter, the strength of the shock wave is 280 to 299 MPa, and cracks generated after shock wave operation is performed on the multiple boreholes form a crack zone, that is, the pre-splitting of the rock in the rock roadway is completed.

Owner:西安闪光能源科技有限公司

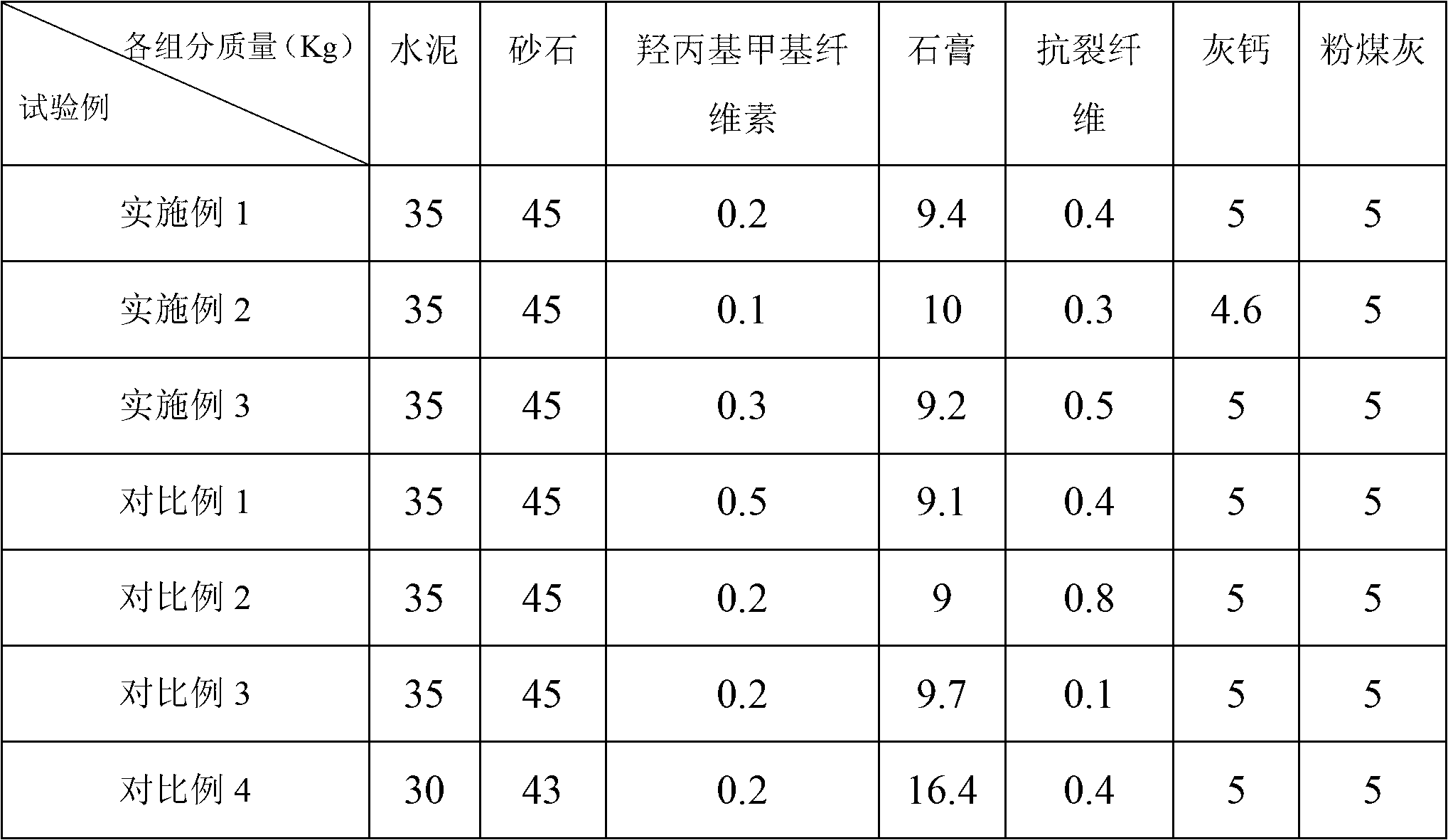

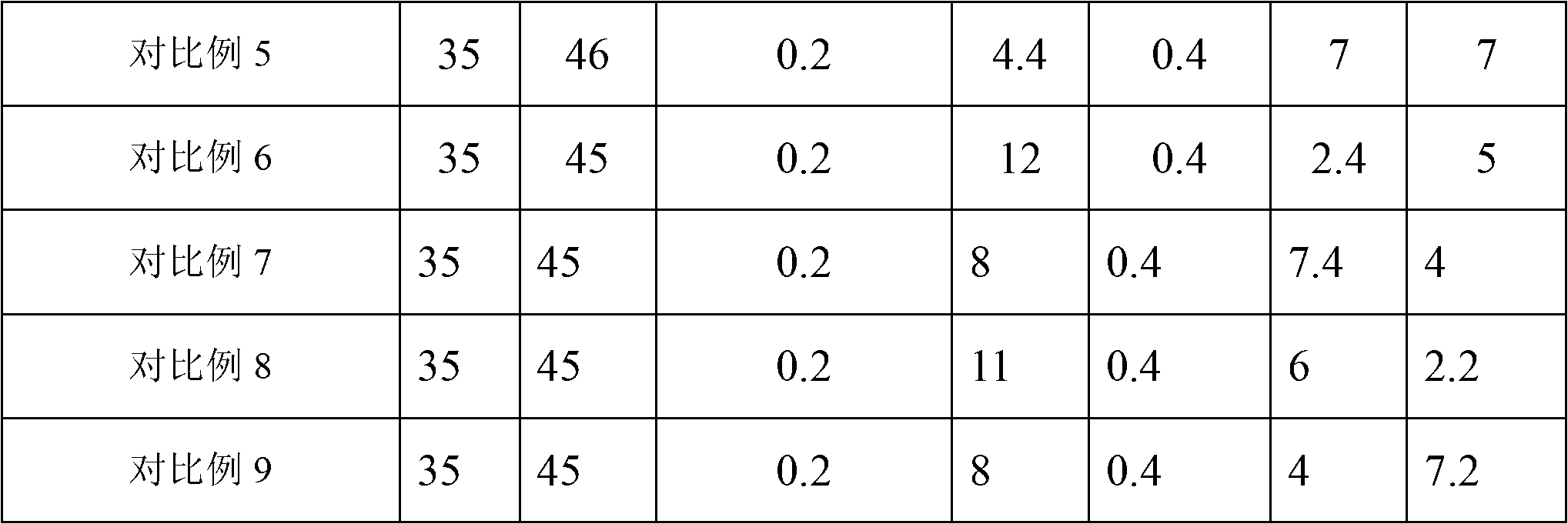

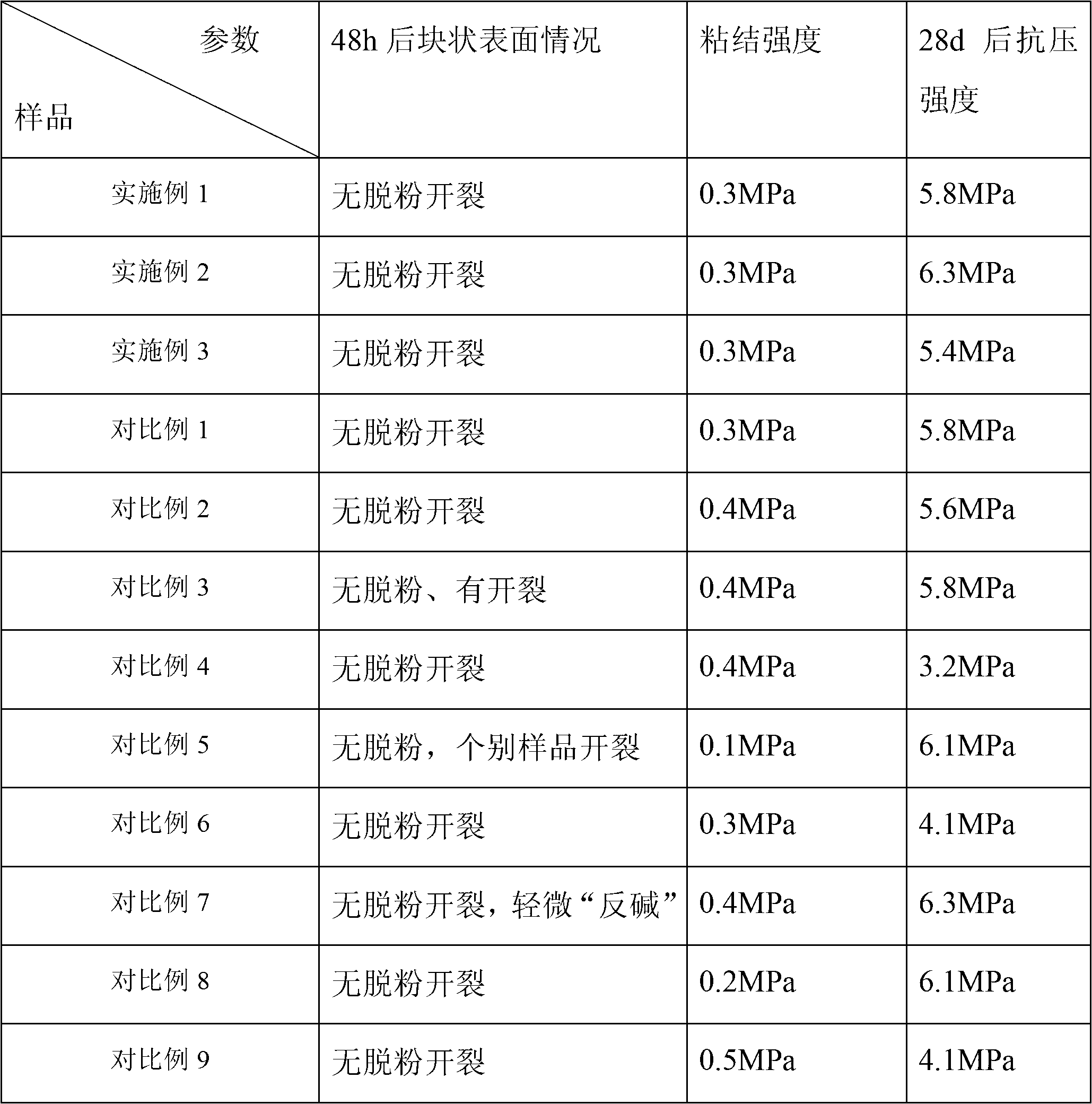

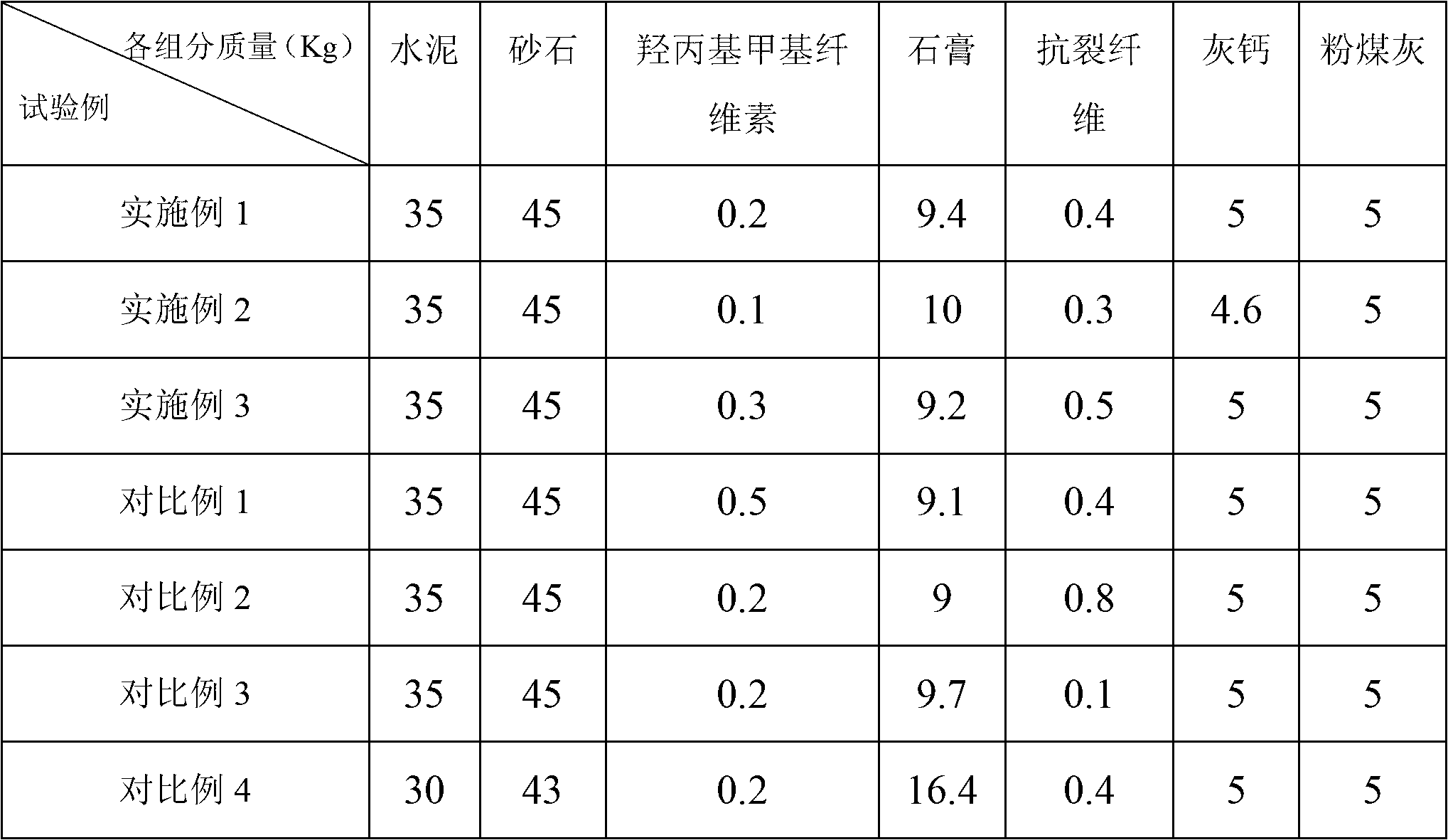

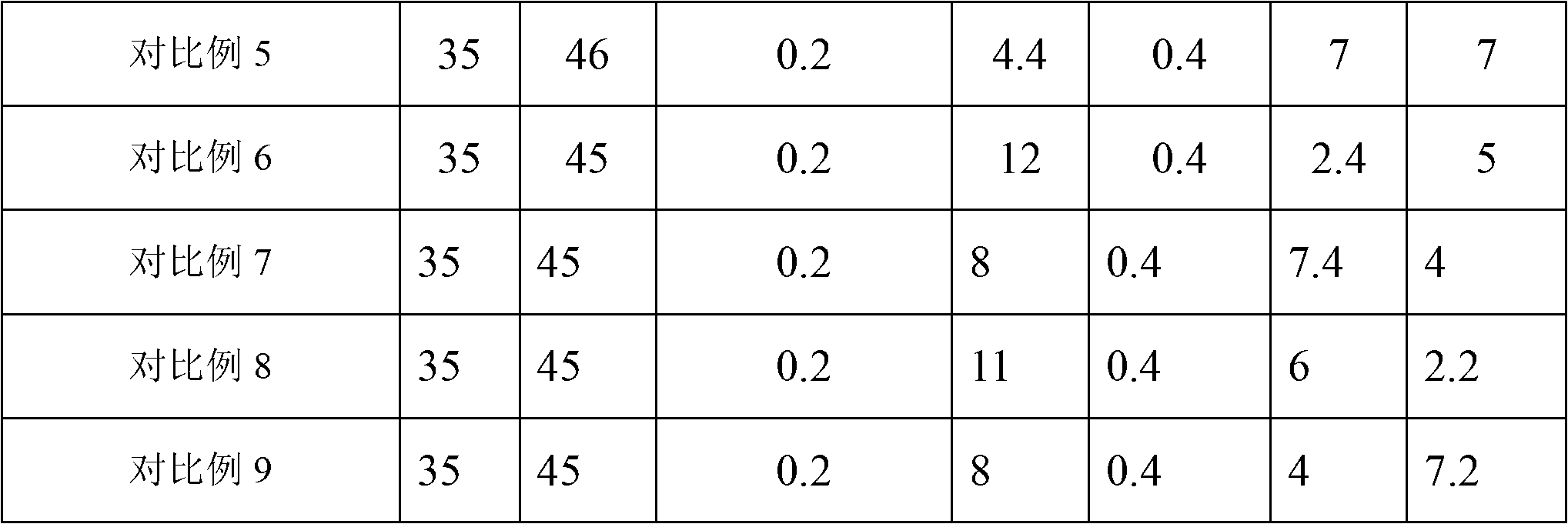

Plastering material for building wall body

ActiveCN102701695AReduce error rateReduce lossCovering/liningsEnvironmental resistanceMethyl cellulose

The invention discloses a plastering material for a building wall body. The plastering material comprises the following components in percentage by mass: 30 to 40 percent of cement, 40 to 50 percent of aggregates, 0.1 to 0.3 percent of water-retaining agent, 5 to 15 percent of gypsum, 0.3 to 0.5 percent of anti-cracking fibers, 3 to 7 percent of sierozem and 3 to 7 percent of coal ash, wherein the water-retaining agent is hydroxypropyl methyl cellulose or methylcellulose; and the anti-cracking fibers are polypropylene fibers or polyacrylonitrile fibers. When the plastering material for the building wall body is used for plastering, the plastering quality is stable, a plastering layer is bonded with a base layer firmly, and cracking and hollowing are avoided. The plastering material for the building wall body is convenient to construct, the labor productivity is improved, and the comprehensive cost is reduced; and when the plastering material is used, dry powder premix bags of a plant area are transported to construction sites, and the powder is stirred slightly by adding water, so that noise pollution and dust pollution which are caused by a large-scale stirring machine are avoided, and the plastering material achieves a positive effect on on-site civilized construction and environment friendliness.

Owner:CHENGDU NO 4 CONSTR ENG +1

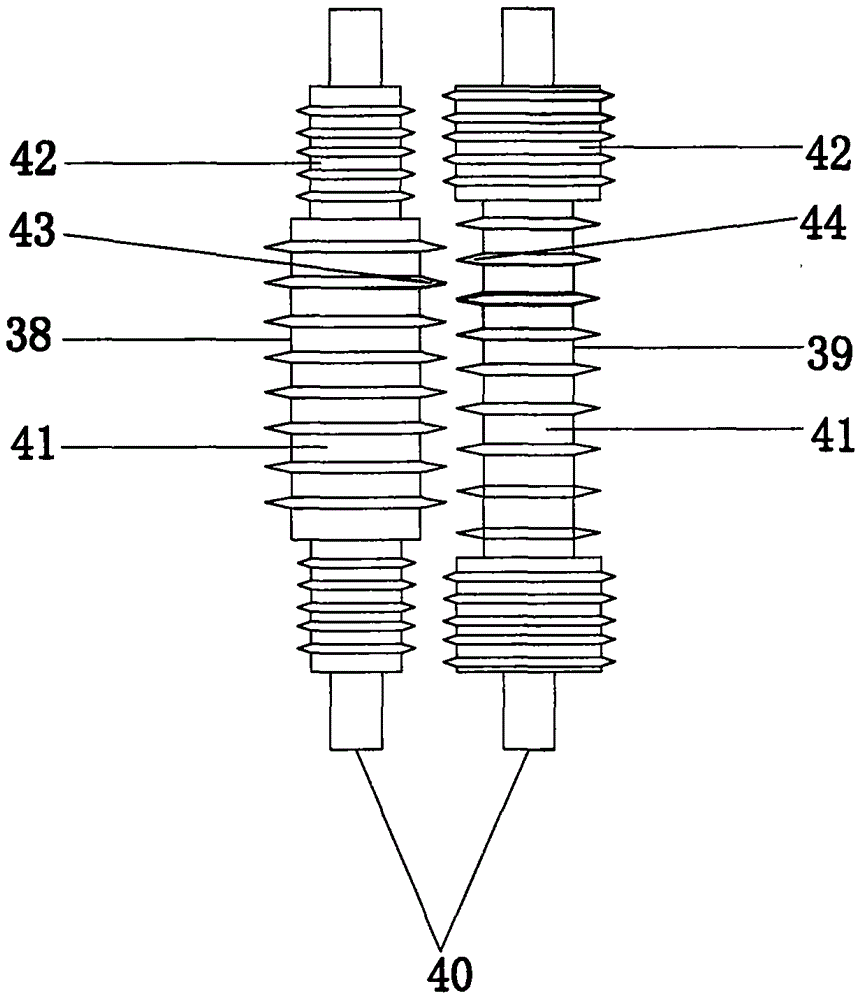

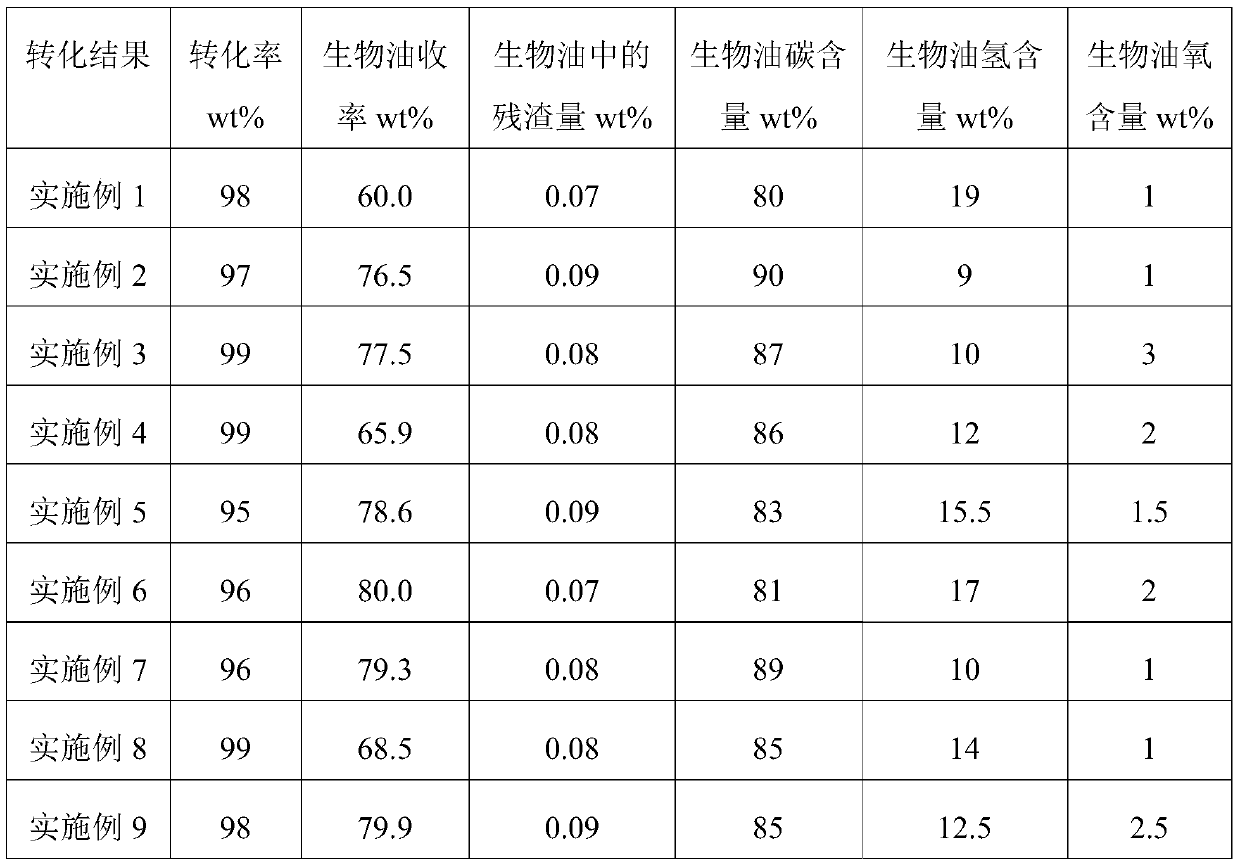

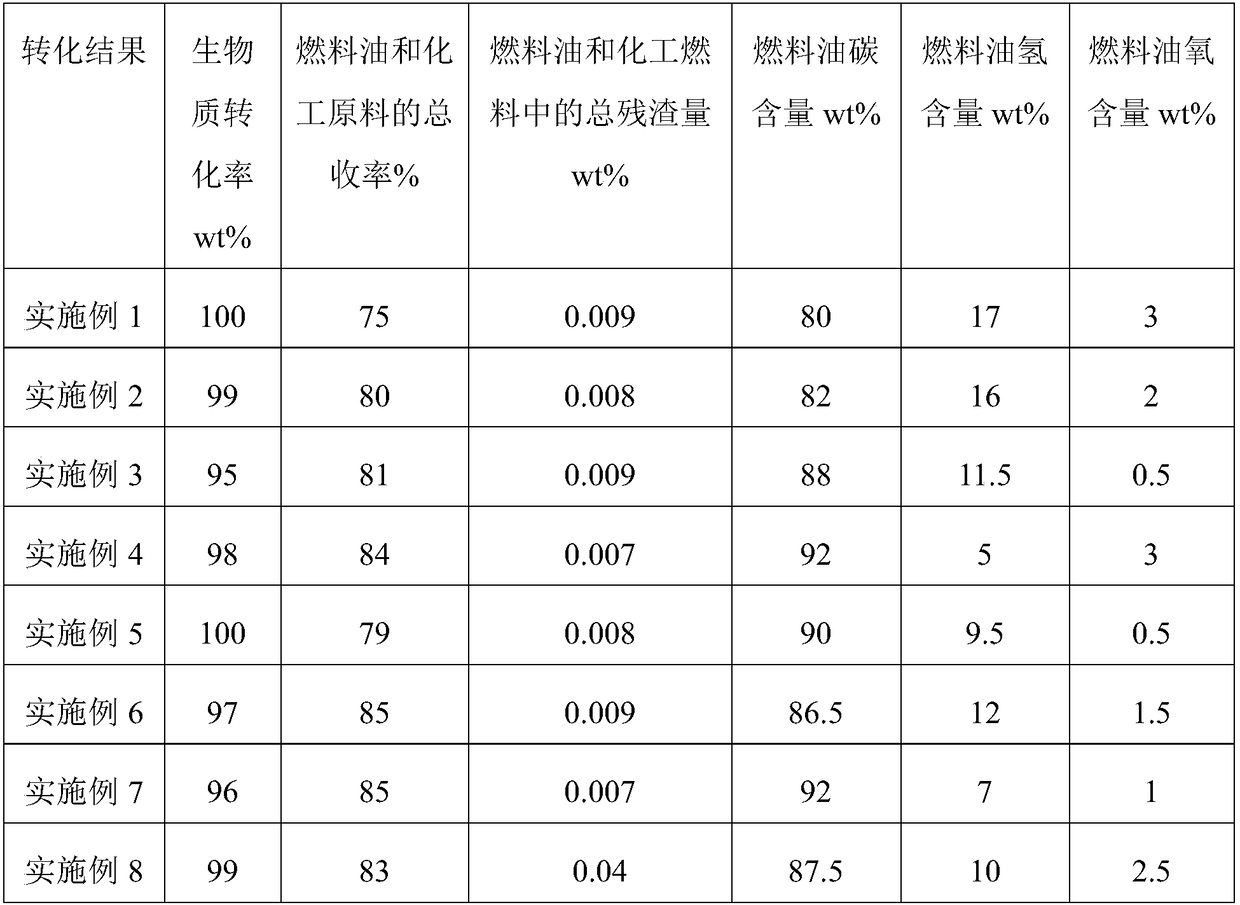

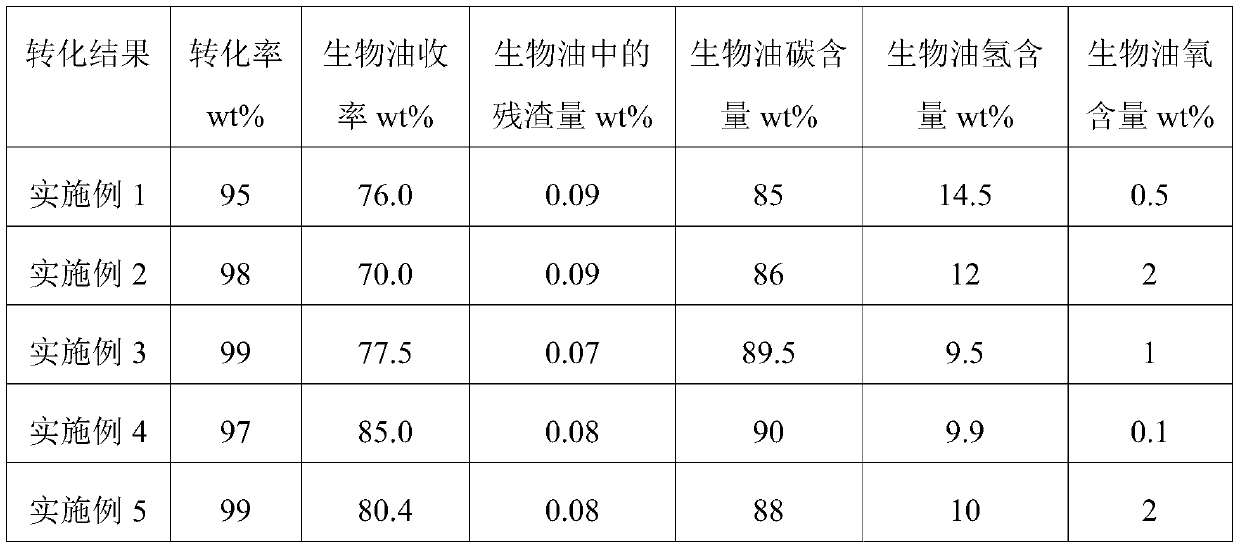

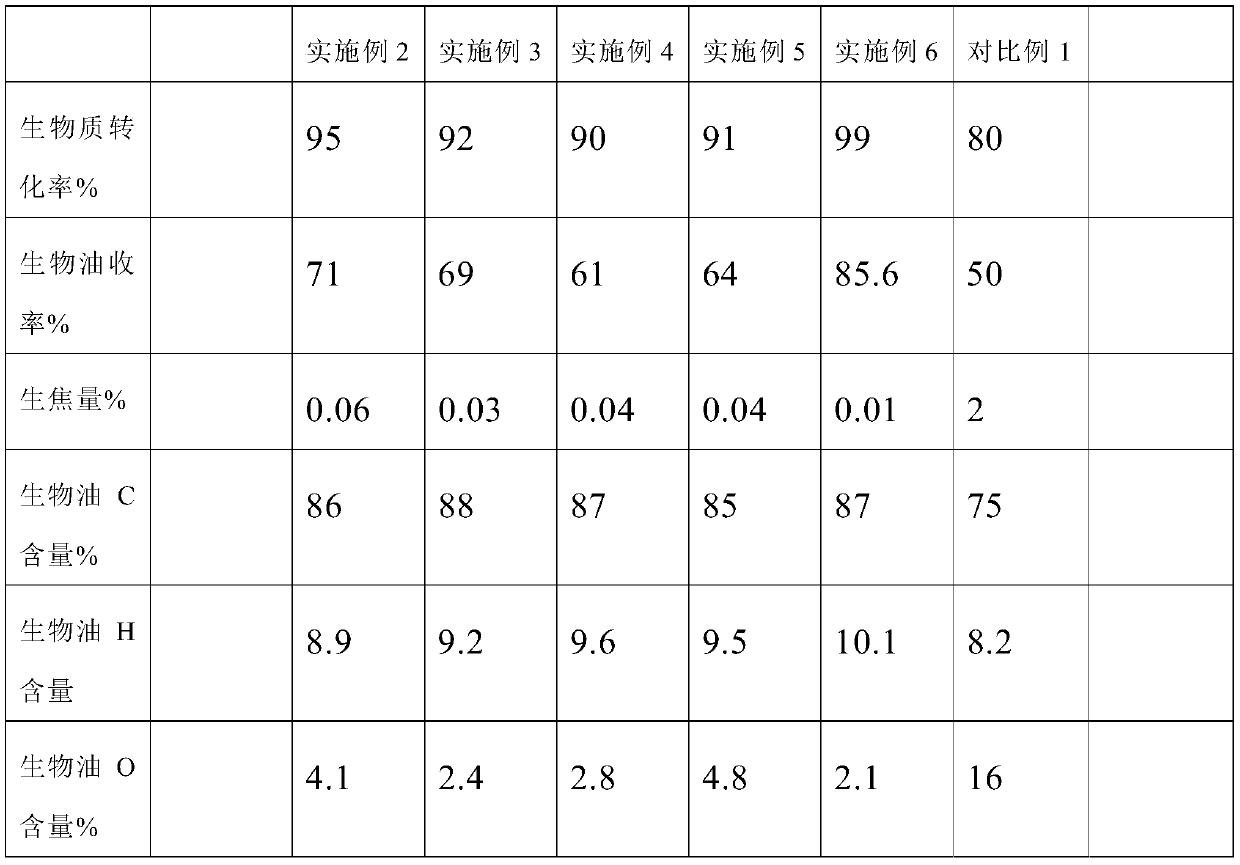

Multistage liquefaction process of biomass

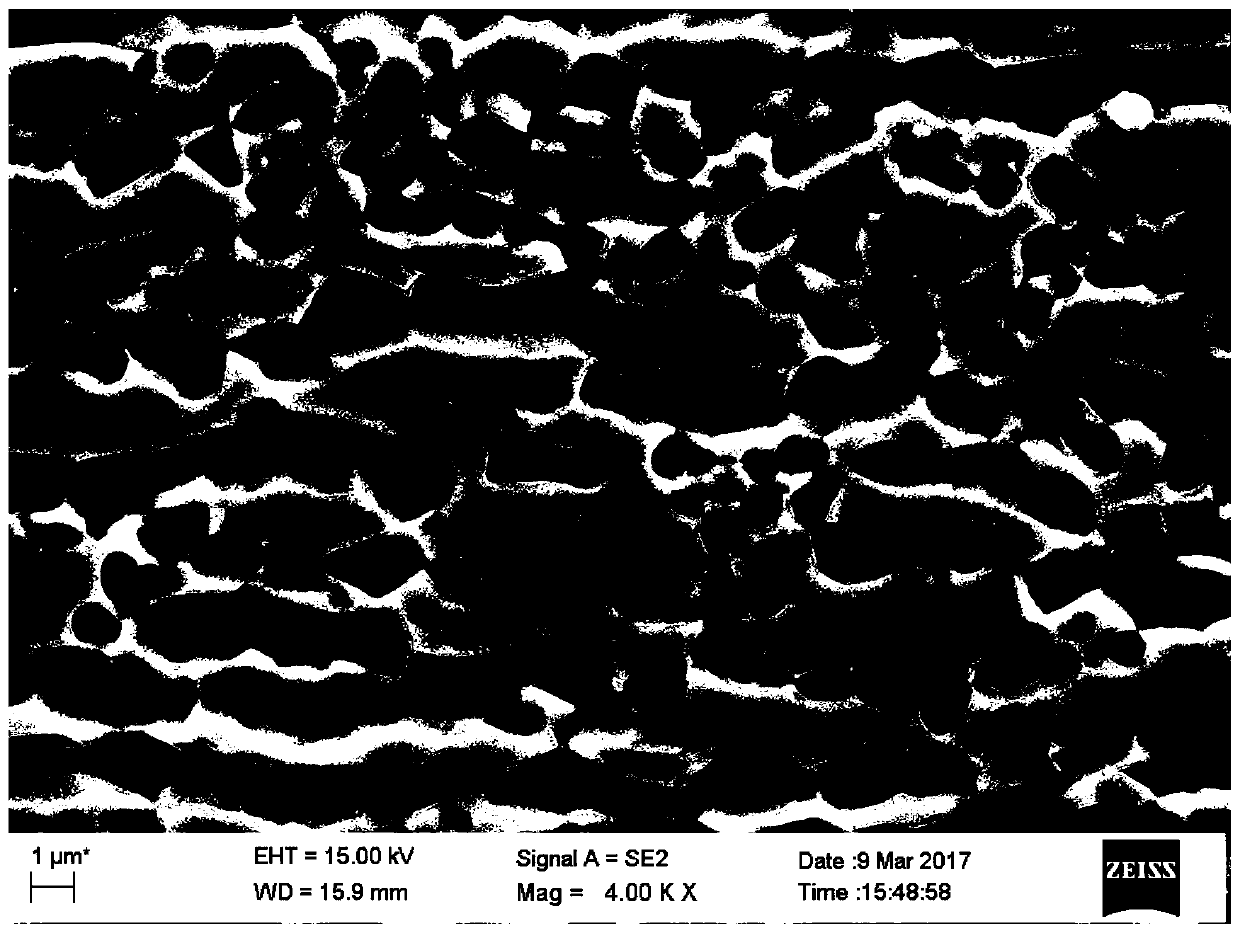

ActiveCN108219817AImprove the efficiency of the liquefaction processGood suspensionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentPorositySlurry

The invention relates to the field of biological energy sources, in particular to a multistage liquefaction process of biomass. Slurry for the biological energy sources is prepared by the steps of sequentially carrying out drying, primary crushing, compressing and secondary crushing on straw, and then mixing the product with a first catalyst to obtain a mixture; adding the obtained mixture into anoil product, and grinding to prepare slurry with a straw concentration of 30-60wt%. According to the multistage liquefaction process of the biomass, a treatment process of first compressing and thensecondary crushing is carried out on the straw for the first time, and the loose straw is sequentially subjected to stages such as rearrangement, mechanical denaturation and shaping rheology by compressing the biomass, so that the volume of the straw is greatly reduced, the porosity of the straw is further reduced, the density and specific gravity of the straw are increased, the straw is more easily dispersed in the oil product, the content of the straw in the oil product is increased, and the concentration of a reaction material is increased; the multistage liquefaction process increases thebiomass conveying capacity of a pump within unit time, guarantees the smooth operation and transportation of the pump, and increases the conversion rate of the biomass.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

One-pot liquefaction process of biomass

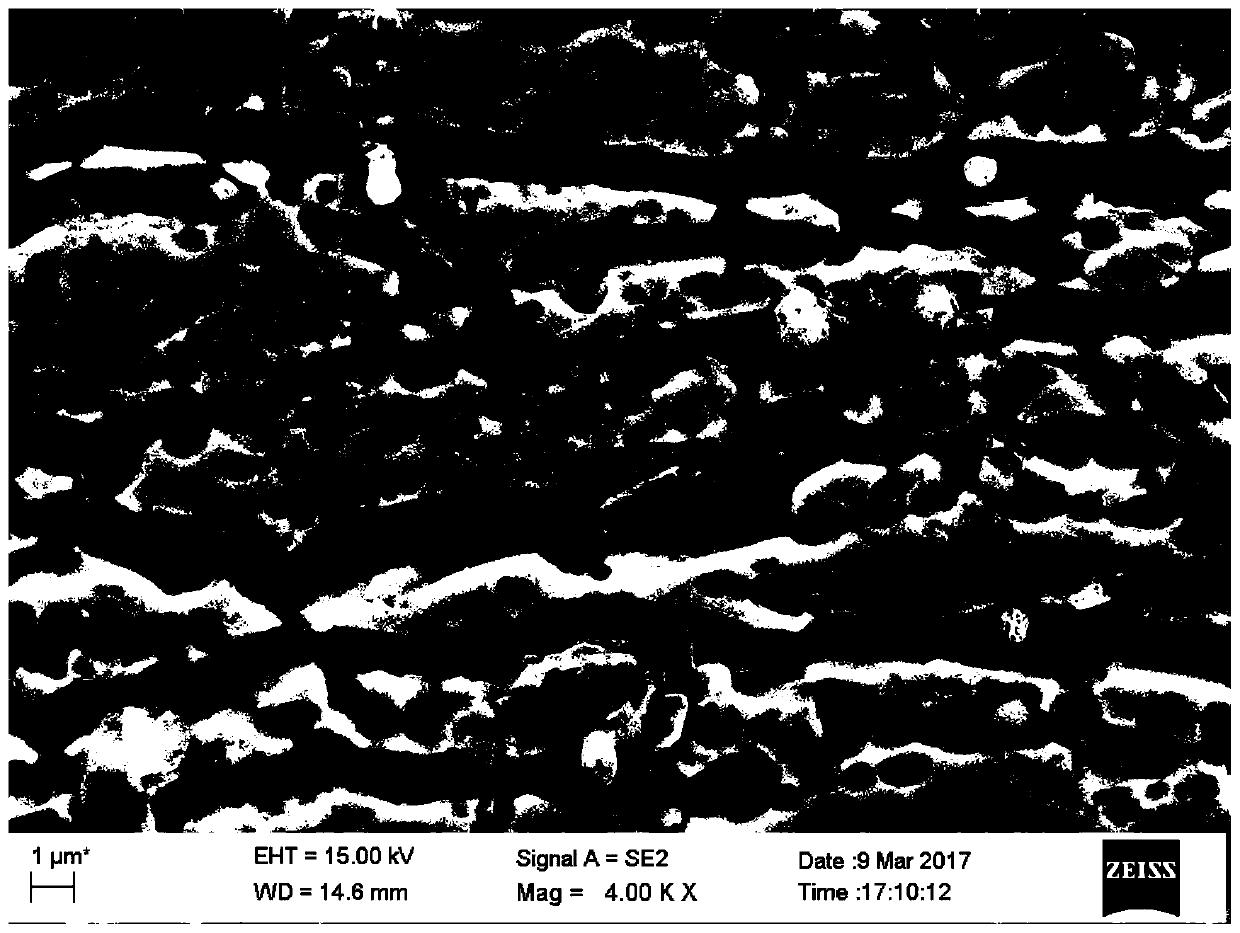

ActiveCN108219818AReduce deliveryLarge volumeLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsHydrogenSlurry

The invention relates to the field of biological energy sources, in particular to a one-pot liquefaction process of biomass. The process comprises the following steps: firstly, preparing slurry containing a catalyst, a vulcanizing agent and biomass, and then introducing hydrogen into the slurry for carrying out a reaction. The slurry is prepared by the steps of sequentially carrying out drying, primary crushing, compressing and secondary crushing on plant oil residue, and then mixing the product with the catalyst and the vulcanizing agent to obtain a mixture; adding the obtained mixture into an oil product, and grinding to prepare slurry, wherein the prepared slurry is biomass slurry with a plant oil residue concentration of 50-65wt%. According to the one-pot liquefaction process of the biomass, a treatment process of first compressing and then secondary crushing is carried out on the plant oil residue for the first time, so that the volume of the plant oil residue is greatly reduced,the plant oil residue is more easily dispersed in the oil product, the content of the plant oil residue in the oil product is increased, and the concentration of a reaction material is increased; theone-pot liquefaction process increases the biomass conveying capacity of a pump within unit time, and guarantees the smooth operation and transportation of the pump.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Co-hydrolysis hydrogenation process for coal and biomass

ActiveCN108277038AHigh densityIncreased accessible areaLiquid hydrocarbon mixture productionHydrocarbon oils treatmentHydrogenation reactionReaction temperature

The invention relates to the technical field of clean energy, in particular to a blending process of coal and biomass. The invention provides a co-hydrolysis hydrogenation process for coal and biomass, the coal and biomass raw materials are subjected to crushing, compression and re-crushing, then the slurry is prepared, and the biomass water coal slurry which is high in solid content and capable of being stably conveyed by a pump is successfully obtained. Hydrogen is introduced into the biomass water coal slurry, the reaction pressure is controlled to be 15-25 MPa, the reaction temperature iscontrolled to be 300-420 DEG C, and finally the biological oil is prepared. The process disclosed by the invention is characterized in that the coal and the biomass are subjected to high-pressure high-temperature hydrolysis under a subcritical or a supercritical state of water, furthermore subjected to cracking and hydrogenation reaction, so that the conversion of the coal and the biomass into thebiological oil is realized. In the process disclosed by the invention, the conversion rate of the coal and the biomass can reach 85-95%, the yield of the biological oil can reach 60-80%, and the residue amount is less than 5%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Coal and biomass co-liquefaction technology

ActiveCN108192652ARealize mixing and liquefactionIncrease contactHydrocarbon oil crackingLiquid hydrocarbon mixture productionKeroseneReaction temperature

The invention relates to the technical field of clean energy, in particular to a coal and biomass co-liquefaction technology. According to the coal and biomass co-liquefaction technology, coal and biomass materials are subjected to crushing, compression and re-crushing treatment, and then slurry is prepared, so that biomass coal oil slurry, with high solid content, capable of being stably conveyedthrough a pump, is obtained, and high-viscosity waste oil which can not serve as a coal and biomass liquefaction solvent in the prior art can be utilized. By leading hydrogen into the biomass coal oil slurry and controlling the reaction pressure to be 15 to 25MPa and the reaction temperature to be 380 to 480 DEG C, biomass oil is formed finally. The technology ensures that coal and biomass are liquefied in high pressure and high temperature environment, and cracking and hydrogenation reaction are further produced, so that the conversion of coal and biomass to biomass oil is realized. In the technology, the conversion ratio of coal and biomass can reach 90 to 95 percent, the yield of biomass oil can reach 40 to 75 percent, and the amount of residue is not greater than 3 percent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Multilayer water curtain filter system

InactiveCN107051062AReduce wind pressure requirementsImprove efficiencyUsing liquid separation agentWater/sewage treatmentFilter systemPulp and paper industry

The invention discloses a multi-layer water curtain filtration system, comprising: a water tank, a water replenishment tank, a fan, a water absorber motor, a cylindrical air duct and a water absorber, wherein the water tank is arranged at the bottom of the filter system; the water replenishment The tank is set above the water tank and connected with the water tank; the fan is set on the top of the filter system to discharge the filtered clean air; the water absorber motor is set below the fan, and its lower end penetrates into the circle In the cylindrical air duct, it is electrically connected to the water absorber located inside the cylindrical air duct; the cylindrical air duct is located in the middle of the filtration system, and the inner wall is provided with vertical ribs to form a multi-layer water curtain The cylindrical air duct is also provided with an air inlet for the outside air to enter; the water absorber is located at the bottom of the cylindrical air duct, and its lower end communicates with the water tank to absorb water from the water tank. Discharge into the cylindrical air duct. The invention can produce multi-layer water curtains, the degree of atomization is large, and the filtering effect is better.

Owner:徐信东 +1

Walnut seedling raising and planting method

InactiveCN107094393AEasy to crackImprove water absorptionSeed and root treatmentSeedlingTime-Consuming

The invention relates to the field of planting and in particular discloses a walnut seedling raising and planting method. According to the method, joints of walnut seedlings are pretreated, so that the shell thickness of the joints of walnut seedlings is reduced, the water absorption property of walnut kernels in the walnut is increased, the respiratory action of the walnut is improved, the time consumed by the whole pretreatment process is short, and the seedling raising efficiency of the walnut can be improved. Moreover, the walnut seedlings can rapidly break through the joints of the walnut shells while emerging, so that rapid emergence is realized; and therefore, rapid growth of the walnut seedlings is guaranteed. According to the scheme, the seedling raising efficiency of the walnut can be improved.

Owner:RENHUAI LONGJING TOWNSHIP LIDONG PLANTING DEV CO LTD

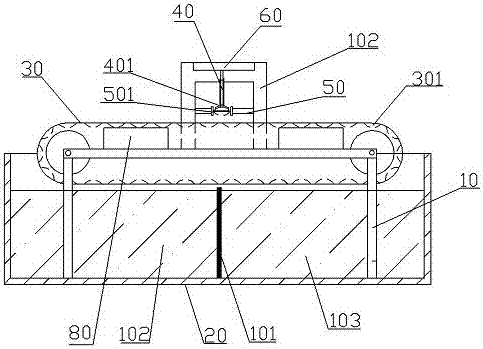

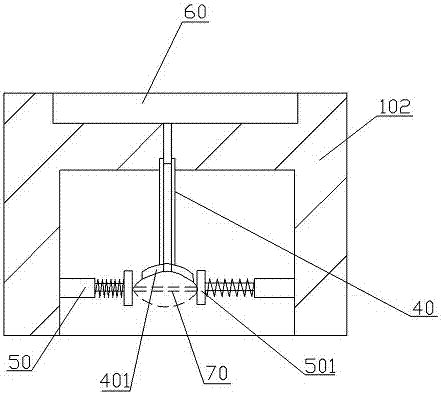

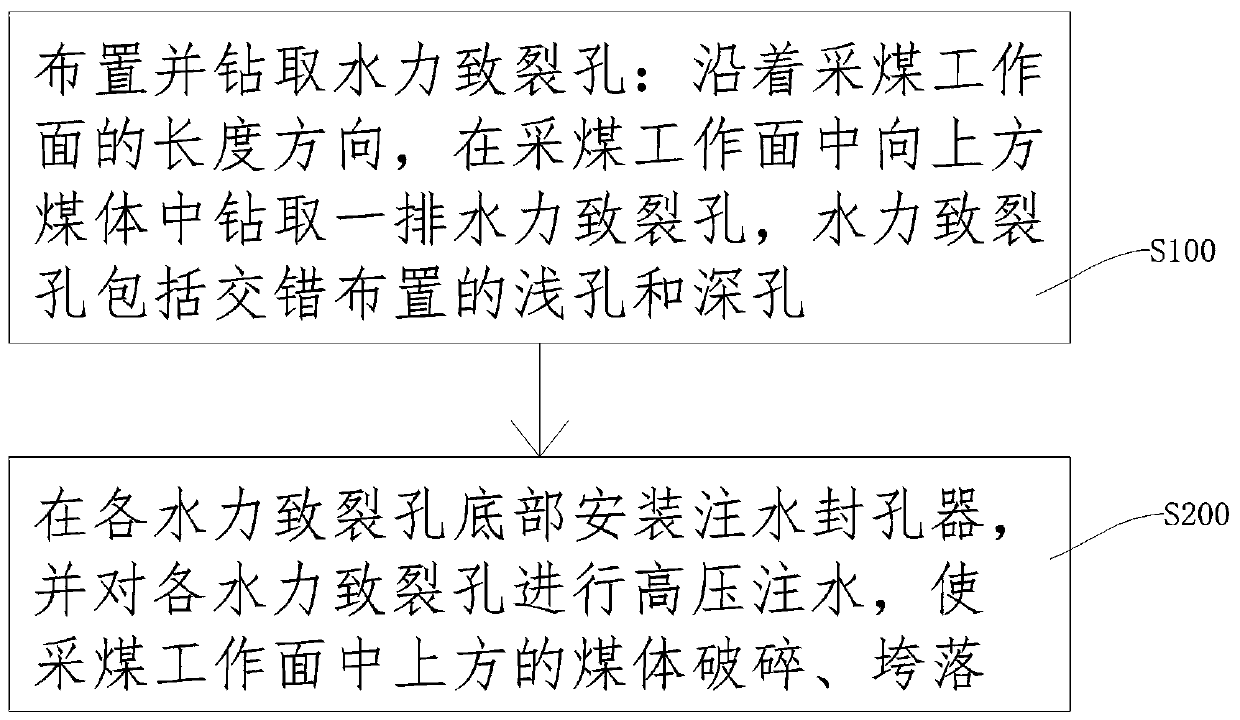

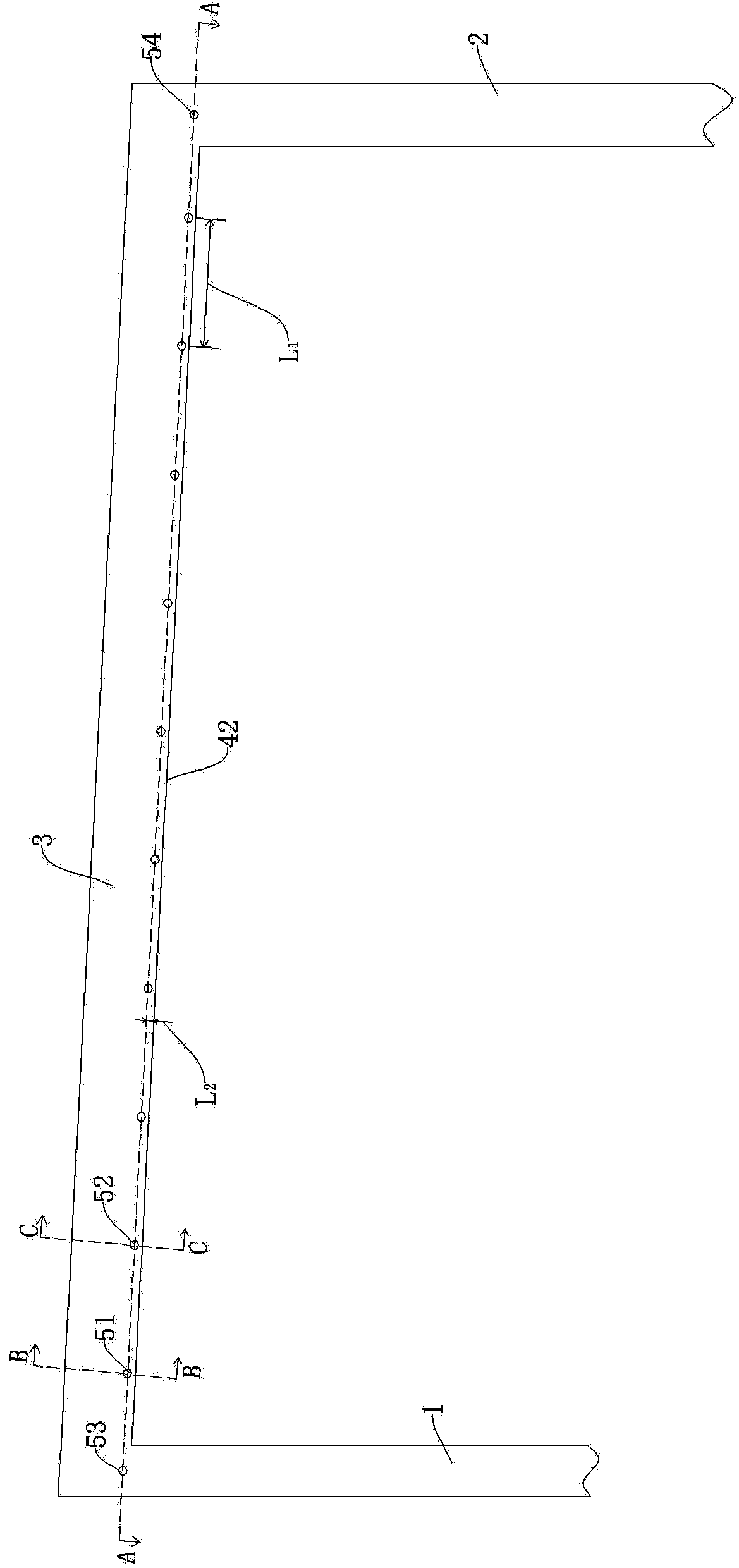

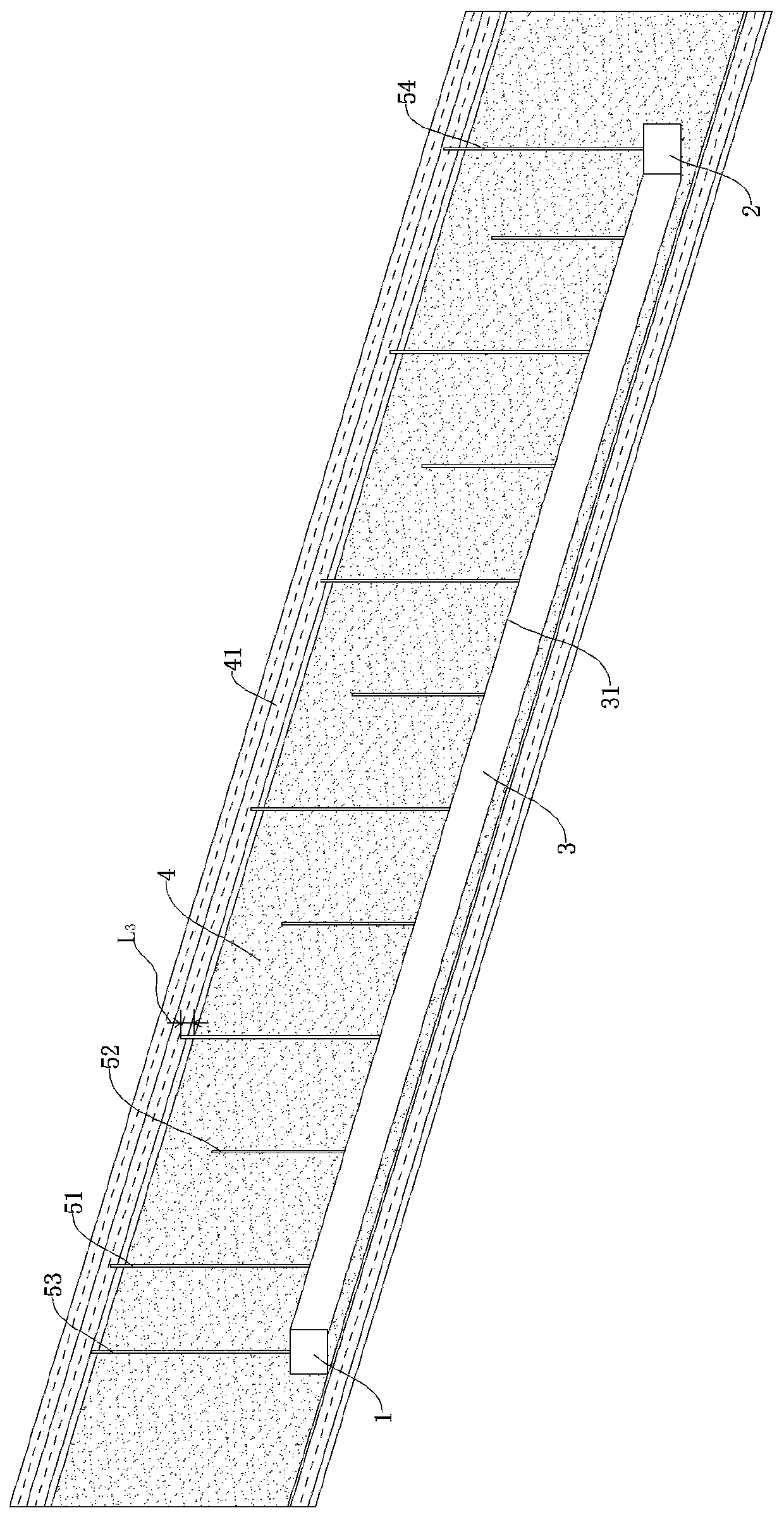

Super-high seam coal face hydraulic fracturing coal mining method

InactiveCN110714763AFully crackedReduce cavingUnderground miningSurface miningMining engineeringHydraulic fracturing

The invention discloses a super-high seam coal face hydraulic fracturing coal mining method. The super-high seam coal face hydraulic fracturing coal mining method includes the following steps of drilling a row of hydraulic fracturing holes in a coal body above a coal face in the length direction of the coal face, wherein the hydraulic fracturing holes include shallow holes and deep holes in a staggered mode; installing a water injecting and hole sealing device at the bottom of each hydraulic fracturing hole, and performing high-pressure water injecting on each hydraulic fracturing hole so thatthe coal body above the coal face can be crushed and caved. The hydraulic fracturing holes in the super-high seam coal face hydraulic fracturing coal mining method are distributed in the high-low staggered mode, hydraulic fracturing can be carried out on different depth layers, top coal fracturing is sufficient, hydraulic fracturing blind areas are avoided, and the top coal caving lumpiness is reduced; construction is simple and convenient when holes are vertically formed in the coal face, the water injecting and hole sealing devices in the drilled holes are not prone to blockage, and recovery is easy under the effect of gravity.

Owner:伊犁永宁煤业化工有限公司

Multi-stage liquefying technology of coal and biomass

ActiveCN108179019AImprove liquidityGood pulpingLiquid hydrocarbon mixture productionHydrogenation reactionEngineering

The invention relates to the technical field of clean energy sources, and particularly provides a multi-stage liquefying technology of coal and biomass. The multi-stage liquefying technology comprisesthe following steps of firstly, compressing the coal and biomass raw materials, crushing, and crushing again; preparing into a slurry, so as to successfully obtain biomass water coal slurry which hashigh solid content and can be stably conveyed by a pump. The multi-stage liquefying technology of coal and biomass has the advantages that the coal and the biomass are hydrolyzed at high pressure andhigh temperature, and the hydrolyzed product is sequentially subject to primary cracking, hydrogenation reaction, deep cracking and hydrogenation reaction under the actions of critical hydrogen, a first catalyst and a second catalyst, so as to convert the coal and biomass into bio-oil and refine the bio-oil; the conversion rate of biomass and coal can reach 97 to 99%, the yield rate of bio-oil can reach 70 to 80%, and the amount of residues is lower than 3%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

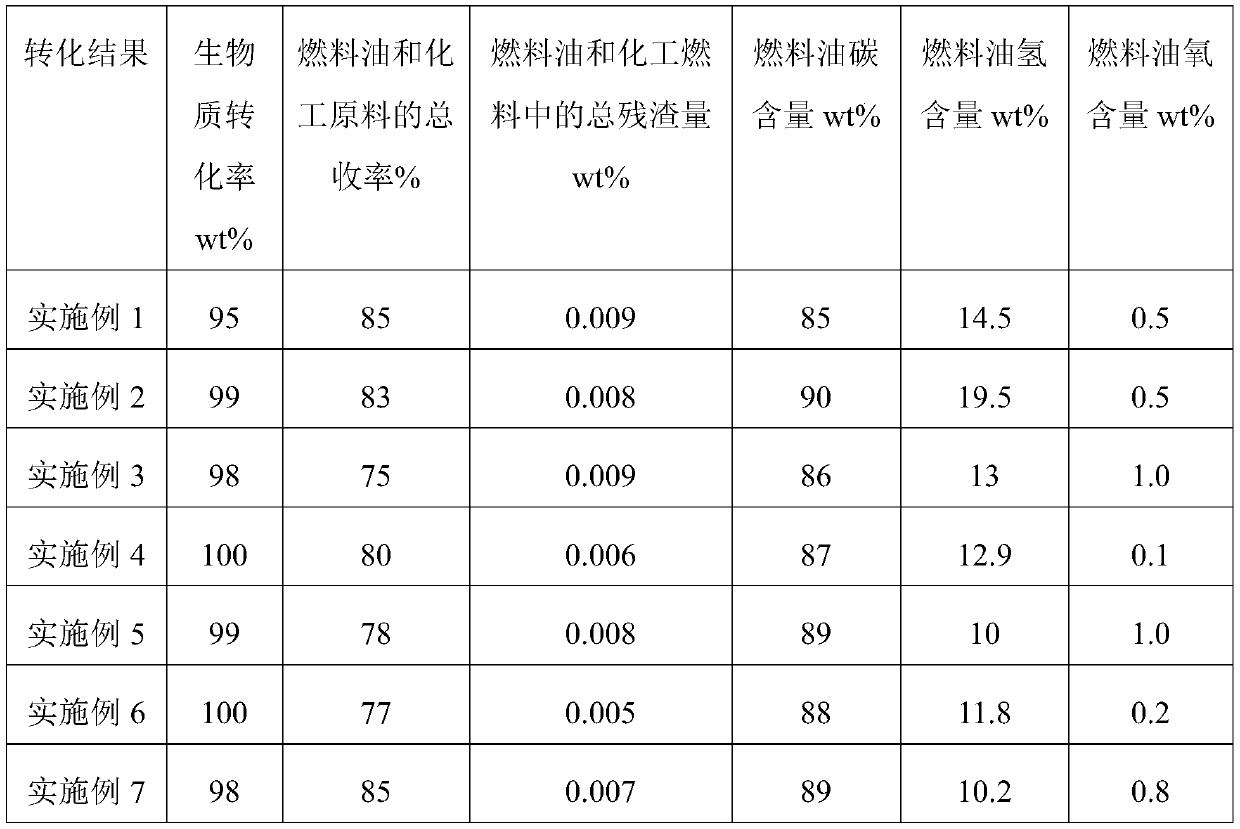

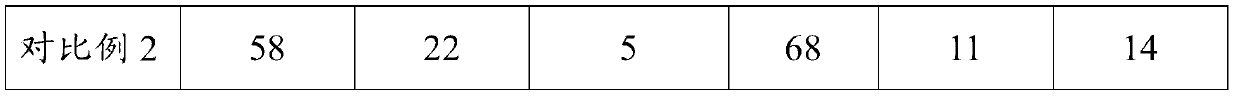

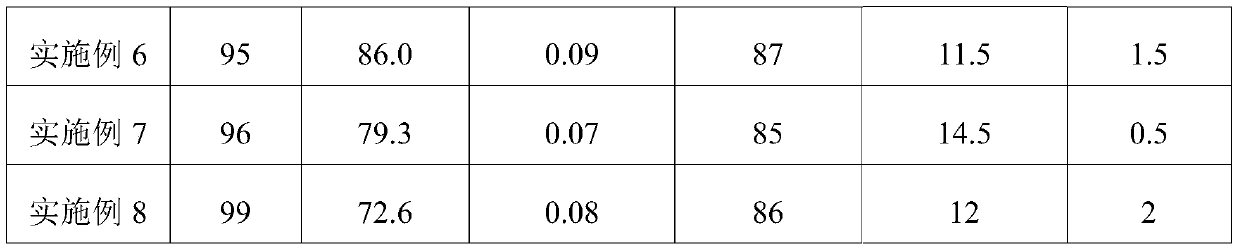

A process for producing fuel oil and chemical raw materials from biomass

ActiveCN108264919BReduce deliveryLarge volumeLiquid hydrocarbon mixture productionHydrocarbon oils treatmentChemical industryVegetable oil

The invention relates to the field of biological energy, particularly to a process for producing fuel oil and chemical industry raw materials by using biomass. The slurry preparation steps comprises:sequentially carrying out drying, primary crushing, compressing and secondary crushing on vegetable oil residue, mixing the obtained material, a first catalyst and a vulcanizing agent to obtain a mixture, adding the mixture to an oil product, and carrying out grinding and slurry preparing to prepare the biomass slurry with the vegetable oil residue concentration of 50-65 wt%. According to the present invention, the vegetable oil residue is sequentially subjected to compressing and secondary crushing, wherein the loose vegetable oil residue is sequentially subjected to re-disposition, mechanical degeneration and other stages by compressing the biomass, such that the density and the specific gravity of the vegetable oil residue are increased so as to easily disperse in the oil product and improve the content in the oil product, increase the concentration of the reaction material, increase the biomass conveying amount of the pump per unit time, and ensure the smooth operation and transportation of the pump.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

One-pot liquefaction process of coal and biomass

ActiveCN108219819BRealize mixing and liquefactionIncrease contactLiquid hydrocarbon mixture productionBio-feedstockHydrogenation reactionWaste oil

The invention relates to the technical field of a clean energy source, in particular to a coal and biomass mixing process. The mixing liquification of coal, biomass and oil is creatively realized forthe first time. Firstly, coal and biomass raw materials are subjected to treatment of crushing, compression and secondary crushing; then, slurry is prepared; biomass coal oil slurry with high solid content and capability of being stably conveyed by a pump is successful obtained, so that high-viscosity waste oil which cannot be used as a coal and biomass liquification solvent in the prior art can also be utilized. Hydrogen gas is introduced into the biomass coal oil slurry for reaction, so that coal and biomass are liquified at high pressure and high temperature; then, cracking and hydrogenation reaction are further performed, so that the conversion of coal and biomass into biological oil is realized. The process provided by the invention has the advantages that the coal and biomass conversion rate can reach 90 to 99 percent; the yield of the biological oil can reach 60 to 80 percent; the residue quantity is not higher than 2.5 weight percent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

One-pot liquefaction process of biomass

ActiveCN108251150BGood suspensionGood dispersionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentPtru catalystPulp and paper industry

The invention discloses a one-pot liquefaction process for a biomass. A slurry is prepared by the following steps: performing drying on straw, performing primary crushing, performing compression, performing secondary crushing, then mixing the crushed straw, a catalyst and a vulcanizing agent to obtain a mixture, and adding the above mixture into water to obtain the slurry with a straw concentration of 35-50wt%. The process provided by the invention performs treatment of first compression and then secondary crushing on the straw for the first time, compression treatment is performed on the biomass, the loose straw is subjected to stages of re-displacement, mechanical deformation and the like in sequence, so that the volume of the straw is greatly reduced, the density and specific gravity can be increased, dispersion of the straw in water is facilitated, the content of the straw in the water can be improved, the amount of the biomass conveyed by a pump per unit time can be improved, so that the efficiency of the overall biomass liquefaction process is improved, the industrial costs and energy consumption are reduced, and smooth operation and delivery of the pump are realized.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A kind of method for preparing kudzu root starch from kudzu root

The present invention relates to a method for preparing lobed kudzuvine root starch from lobed kudzuvine root. The method comprises: selecting high-quality lobed kudzuvine root as a raw material, cleaning, and carrying out a water addition and slurry grinding treatment to obtain a lobed kudzuvine root slurry mixture; sequentially adding cellulase and pectinase to the lobed kudzuvine root slurry mixture, and controlling conditions to carry out hydrolysis; carrying out filtering, precipitation and separation on the enzymolysis mixing solution through a filtration cloth, taking the starch precipitate, adding hydrogen peroxide, and controlling conditions to carry out a bleaching treatment; filtering to obtain wet starch; and carrying out low temperature vacuum drying to obtain the lobed kudzuvine root starch finished product. The method has characteristics of rational process, simple operation, short production cycle, no environmental pollution, high starch extraction rate, and high starch whiteness.

Owner:山东海普盾生物科技有限公司

A multi-stage liquefaction process of coal and biomass

ActiveCN108285808BRealize mixing and liquefactionIncrease contactBiofuelsLiquid hydrocarbon mixture productionHigh pressureClean energy

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

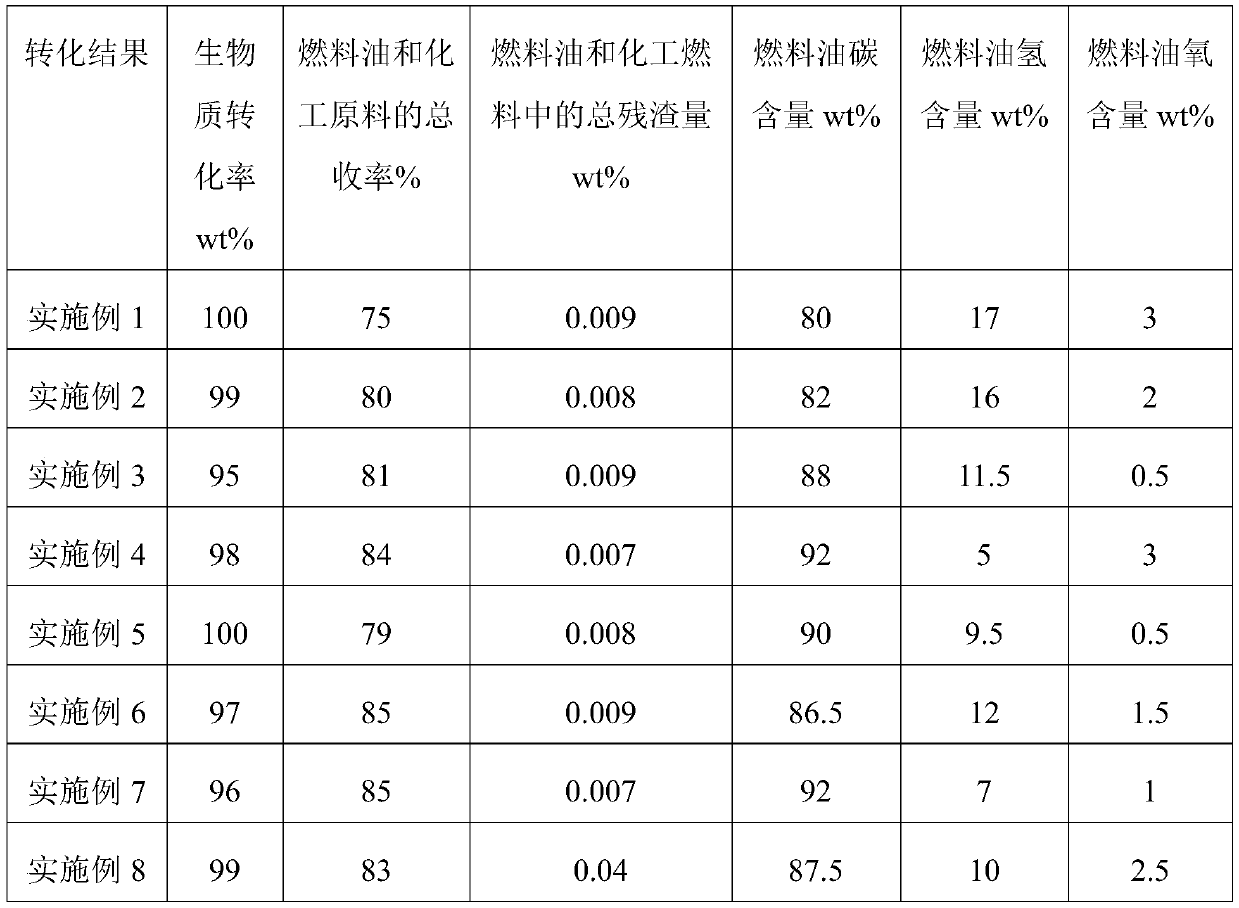

A process for producing fuel oil and chemical raw materials using coal and biomass

ActiveCN108251149BRealize mixing and liquefactionIncrease contactLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionWaste oil

The invention relates to the technical field of clean energy, and in particular relates to a co-processing process of coal and biomass. The invention creatively realizes mixing and liquefaction of thecoal, the biomass and oil for the first time. ''Crushing + compressing + re-crushing'' treatment is performed on the coal and biomass raw materials, a slurry is prepared, a biomass kerosene slurry which has a high solid content and can be conveyed smoothly by a pump is successfully obtained, and therefore waste oil with high viscosity which cannot be used as a liquefaction solvent of the coal andthe biomass in the prior art can also be utilized. According to the process provided by the invention, primary cracking is performed on the coal and the biomass, a hydrogenation reaction is performed, deep cracking is performed, and a hydrogenation reaction is performed, so that transformation from the coal and the biomass to fuel oil and chemical raw materials is realized, the conversion rate ofthe coal and the biomass can reach 90-99%, the yield of the fuel oil can reach 60-80%, and the content of residues is less than 3%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Plastering material for building wall body

The invention discloses a plastering material for a building wall body. The plastering material comprises the following components in percentage by mass: 30 to 40 percent of cement, 40 to 50 percent of aggregates, 0.1 to 0.3 percent of water-retaining agent, 5 to 15 percent of gypsum, 0.3 to 0.5 percent of anti-cracking fibers, 3 to 7 percent of sierozem and 3 to 7 percent of coal ash, wherein the water-retaining agent is hydroxypropyl methyl cellulose or methylcellulose; and the anti-cracking fibers are polypropylene fibers or polyacrylonitrile fibers. When the plastering material for the building wall body is used for plastering, the plastering quality is stable, a plastering layer is bonded with a base layer firmly, and cracking and hollowing are avoided. The plastering material for the building wall body is convenient to construct, the labor productivity is improved, and the comprehensive cost is reduced; and when the plastering material is used, dry powder premix bags of a plant area are transported to construction sites, and the powder is stirred slightly by adding water, so that noise pollution and dust pollution which are caused by a large-scale stirring machine are avoided, and the plastering material achieves a positive effect on on-site civilized construction and environment friendliness.

Owner:CHENGDU NO 4 CONSTR ENG +1

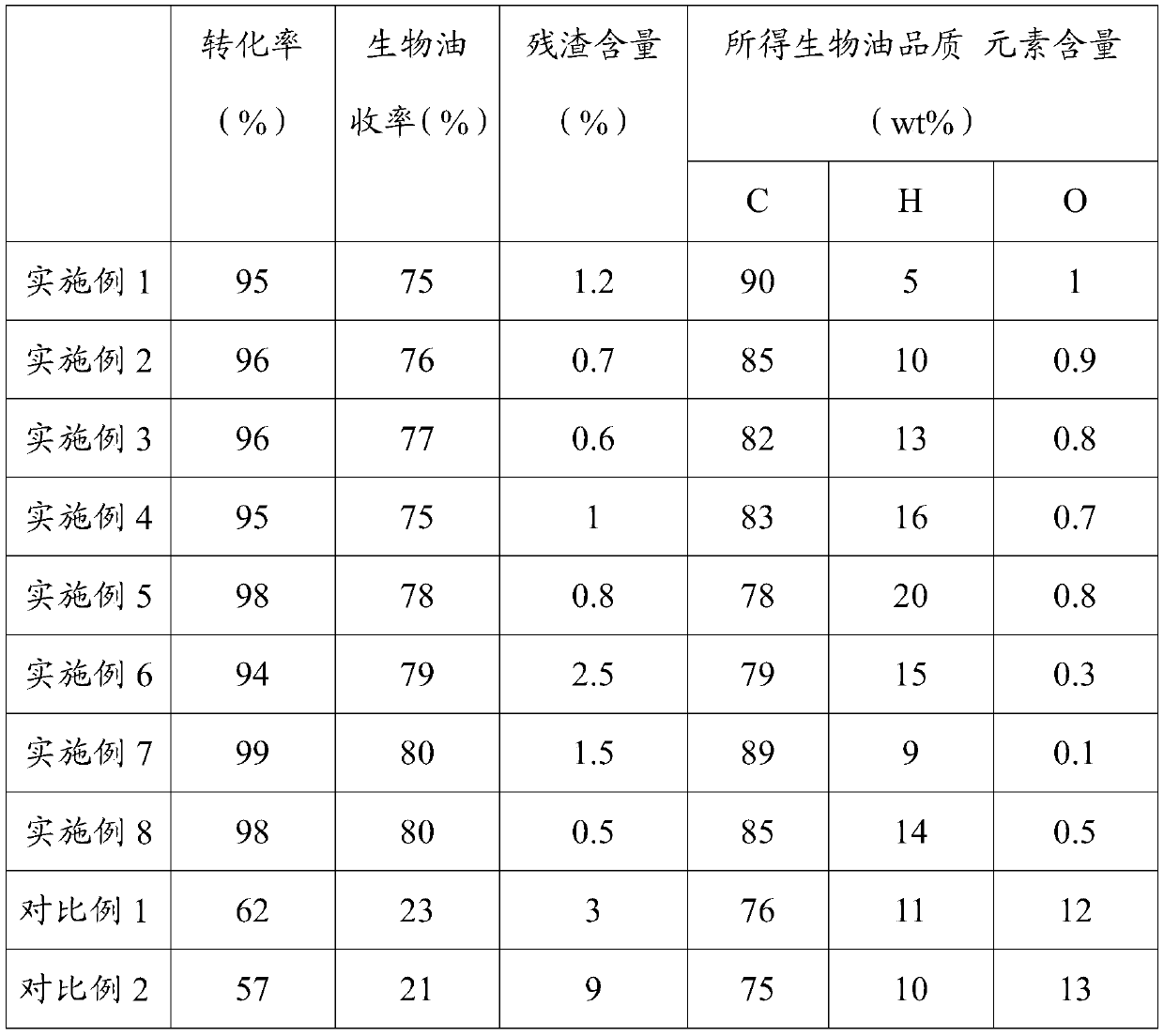

A multistage liquefaction process of biomass

ActiveCN108085036BImprove hydrogenation performanceAcidicLiquid hydrocarbon mixture productionHydrocarbon oils treatmentPtru catalystHydrogenation reaction

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

A multi-stage liquefaction process of coal and biomass

ActiveCN108179019BHigh densityIncreased accessible areaLiquid hydrocarbon mixture productionPtru catalystHydrogenation reaction

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

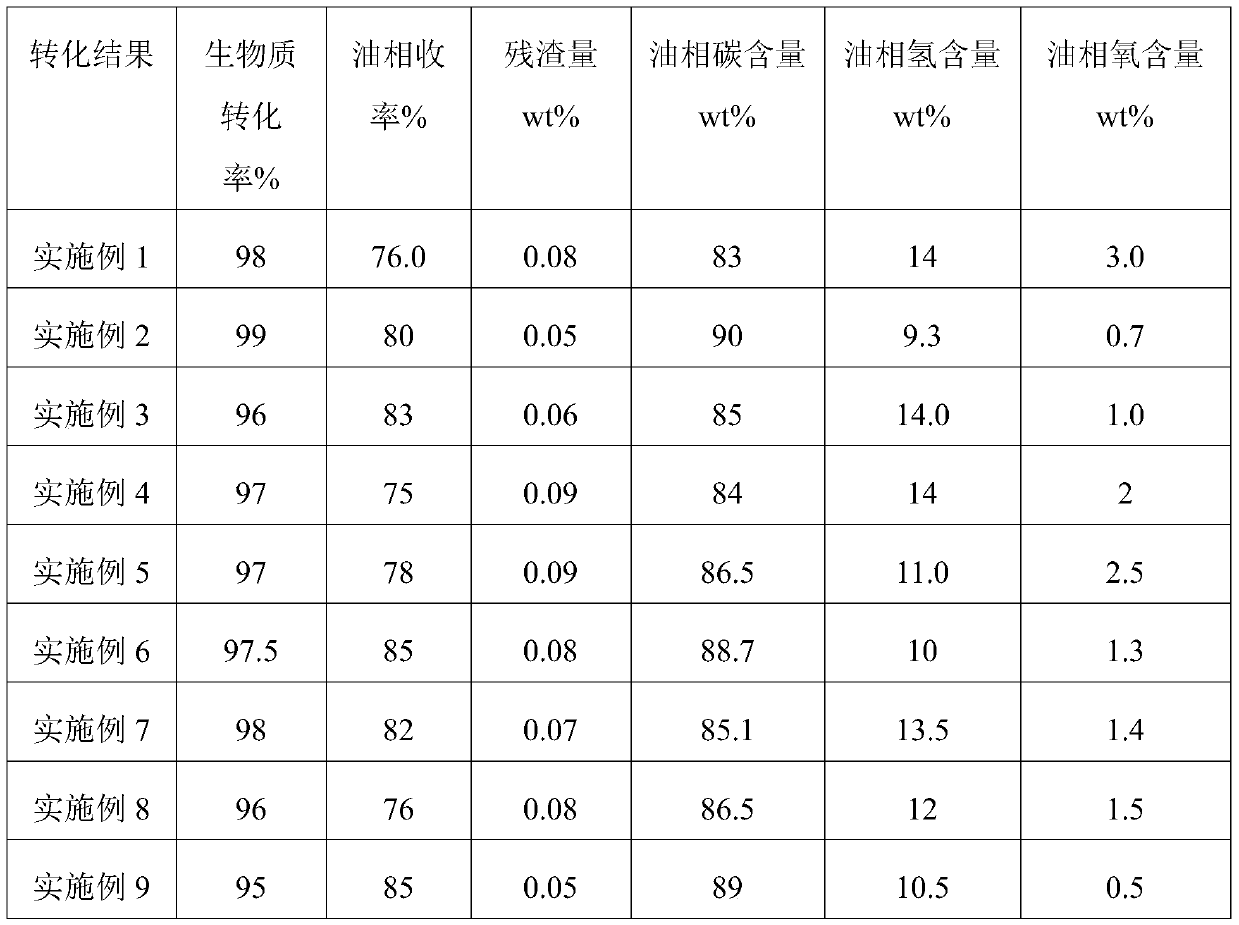

Process for producing fuel oil and chemical materials by utilizing biomass

ActiveCN108315040AReduce deliveryImprove the efficiency of the liquefaction processLiquid hydrocarbon mixture productionFuelsOil phaseSlurry

The invention relates to the field of biological energy, in particular to a process for producing fuel oil and chemical materials by utilizing biomass. The slurry is prepared by the following steps: performing drying, primary crushing, compression and secondary crushing on straws, mixing the powder, a first catalyst and a vulcanizing agent to obtain a mixture, adding the mixture into an oil product, and grinding to prepare slurry, namely the biomass slurry with the straw concentration of 30 to 60 percent by weight. The straws are initiatively subjected to the treatment process for compressingand crushing for the second time, the biomass is subjected to compression treatment, and the loose straws are subjected to the stages of ranking again, mechanical degeneration and shaping rheology, sothat the density and the specific gravity of the straws are increased, the straws are dispersed into the oil product, the content of the straws in the oil product can be increased, the concentrationof the reaction materials is increased, the quantity of conveying the biomass by the pump within unit time is increased, stable operation and conveying of the pump are guaranteed, and the conversion rate of the biomass and the yield of the oil phase are increased.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

One-pot liquefaction process of biomass

ActiveCN108264916BGood suspensionGood dispersionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsVegetable oilProcess engineering

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A process for producing fuel oil and chemical raw materials from biomass

ActiveCN108085047BImprove conversion rateHigh yieldHeterogenous catalyst chemical elementsLiquid hydrocarbon mixture productionPtru catalystHydrogenation reaction

The invention relates to the field of bioenergy, and in particular relates to a process for producing fuel oil and chemical raw materials from biomass. The process for producing the fuel oil and the chemical raw materials from the biomass comprises the following steps: preparing slurry containing a first catalyst, a vulcanizing agent and the biomass, introducing hydrogen into the slurry to performfirst-stage hydrogenation reaction, and controlling the reaction pressure at 13 to 25 MPa and the reaction temperature at 200-350 DEG C to obtain a first-stage hydrogenation product; mixing a secondcatalyst, a vulcanizing agent and solvent oil to prepare catalyst oil slurry, adding the catalyst oil slurry, introducing the hydrogen into the catalyst oil slurry to perform second-stage hydrogenation reaction, and controlling the reaction pressure at 13 to 25 MPa and the reaction temperature at 380-480 DEG C to obtain a second-stage hydrogenation product; and separating the second-stage hydrogenation product to respectively obtain the fuel oil and the chemical raw materials. The process for producing the fuel oil and the chemical raw materials from the biomass has the advantages of high reaction efficiency, no coke production and high liquid yield.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

A process for using biomass to produce fuel oil and chemical raw materials

ActiveCN108315040BReduce deliveryImprove the efficiency of the liquefaction processLiquid hydrocarbon mixture productionFuelsPtru catalystProcess engineering

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

One-pot liquefaction process of biomass

ActiveCN108219818BReduce deliveryLarge volumeLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsPtru catalystVegetable oil

The invention relates to the field of biological energy sources, in particular to a one-pot liquefaction process of biomass. The process comprises the following steps: firstly, preparing slurry containing a catalyst, a vulcanizing agent and biomass, and then introducing hydrogen into the slurry for carrying out a reaction. The slurry is prepared by the steps of sequentially carrying out drying, primary crushing, compressing and secondary crushing on plant oil residue, and then mixing the product with the catalyst and the vulcanizing agent to obtain a mixture; adding the obtained mixture into an oil product, and grinding to prepare slurry, wherein the prepared slurry is biomass slurry with a plant oil residue concentration of 50-65wt%. According to the one-pot liquefaction process of the biomass, a treatment process of first compressing and then secondary crushing is carried out on the plant oil residue for the first time, so that the volume of the plant oil residue is greatly reduced,the plant oil residue is more easily dispersed in the oil product, the content of the plant oil residue in the oil product is increased, and the concentration of a reaction material is increased; theone-pot liquefaction process increases the biomass conveying capacity of a pump within unit time, and guarantees the smooth operation and transportation of the pump.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

One-pot liquefaction process of biomass

ActiveCN108085048BAchieve conversionPromote hydrolysisLiquid hydrocarbon mixture productionBio-feedstockPtru catalystProcess engineering

The invention discloses a one-pot liquefaction process of biomass, which includes the following steps: preparing a slurry containing a catalyst, a vulcanizing agent and biomass, passing hydrogen gas into the slurry to react, and controlling the reaction pressure to 13-25 MPa. The reaction temperature is 300 to 500°C, and bio-oil is finally produced; the catalyst includes amorphous alumina or biomass carbon loaded with active components, and the active components are selected from oxides of metals in Group VIB, VIIB or VIII of the periodic table of elements. one or more of them. The process provided by the invention has high reaction efficiency, no coke generation and high liquid yield.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com