Rock pre-splitting method for mine rock roadway driving face

A technology for excavating working face and rock, applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of high risk and poor environmental protection, and achieve the effect of improving efficiency, improving effect, improving environmental protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

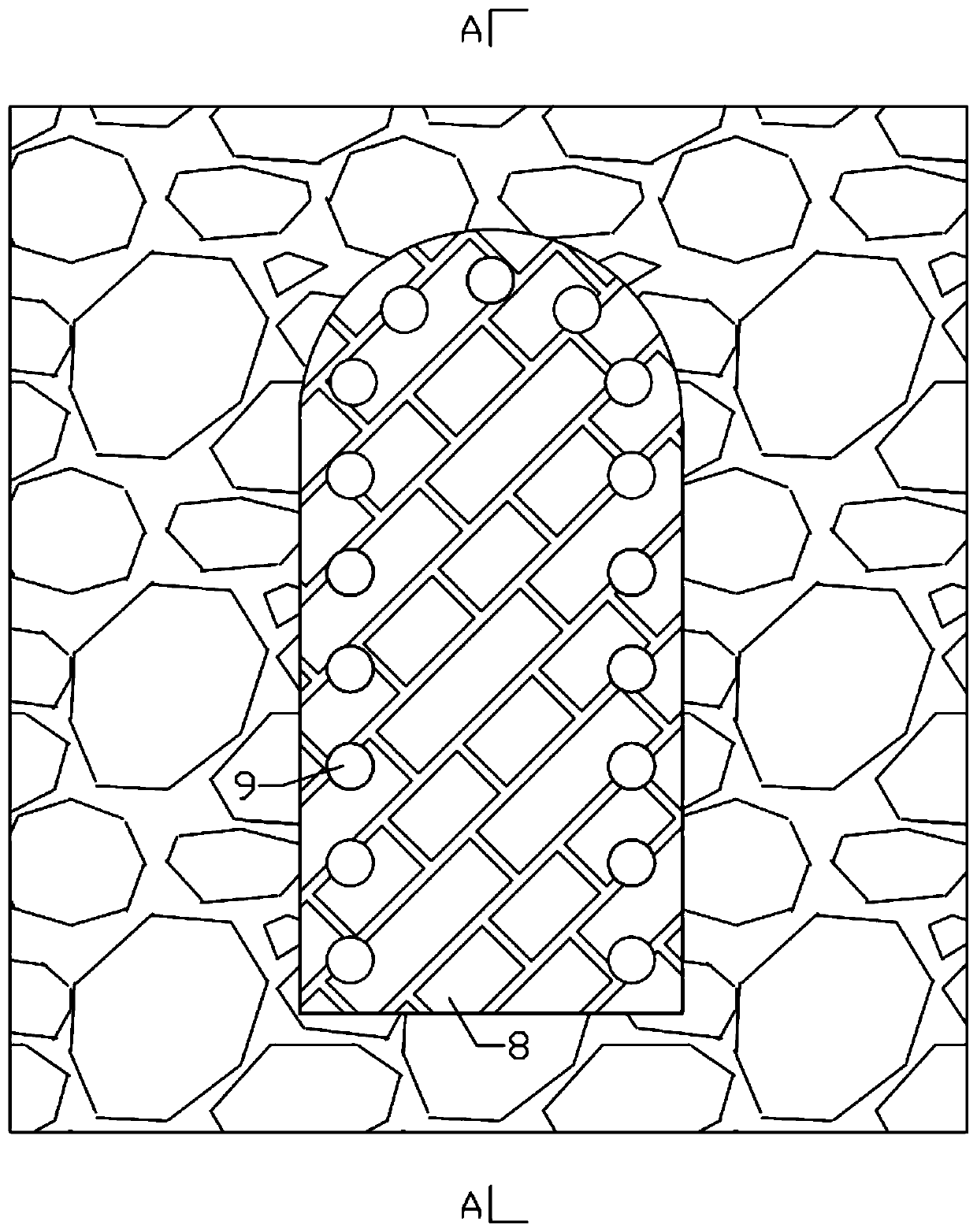

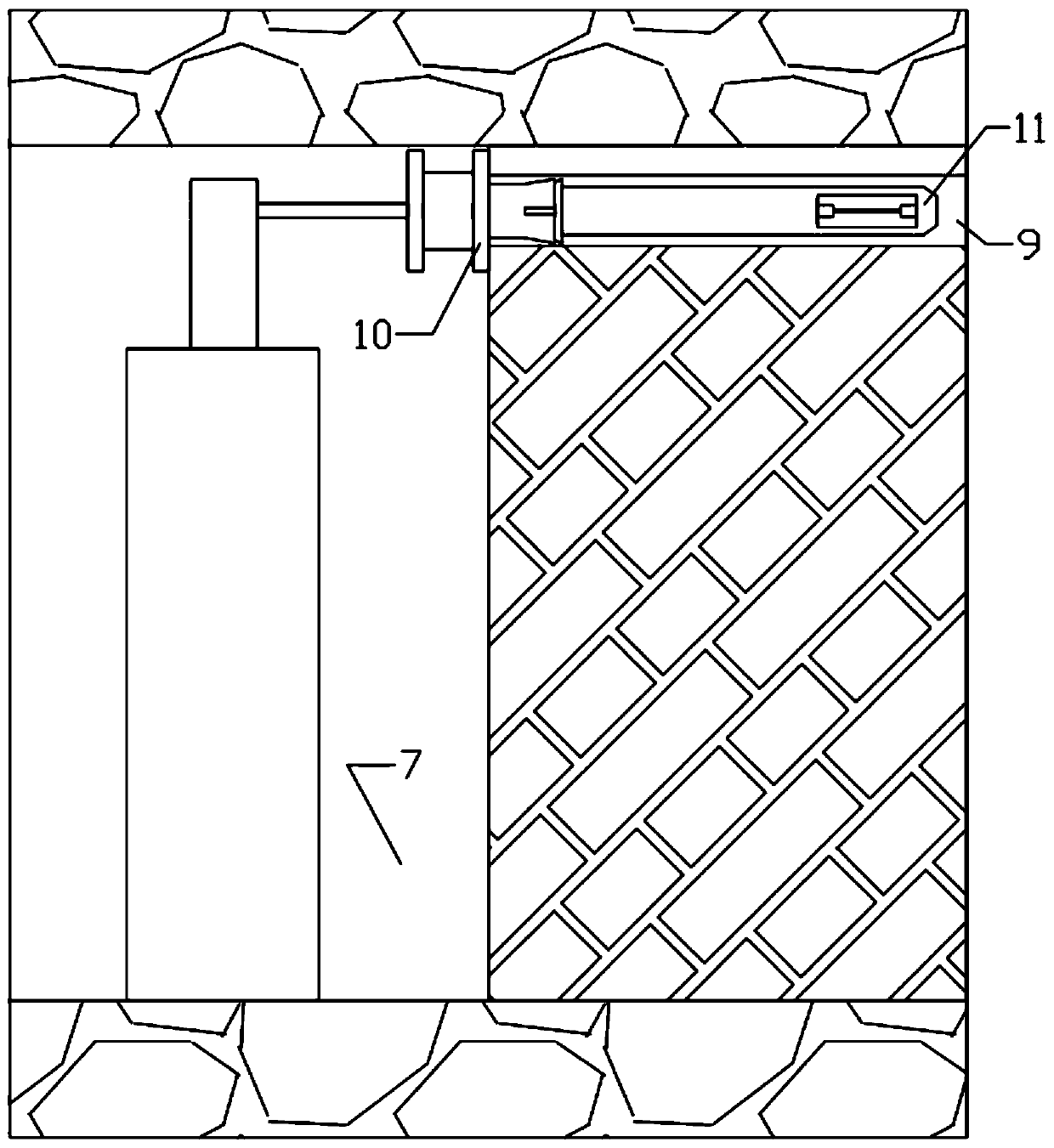

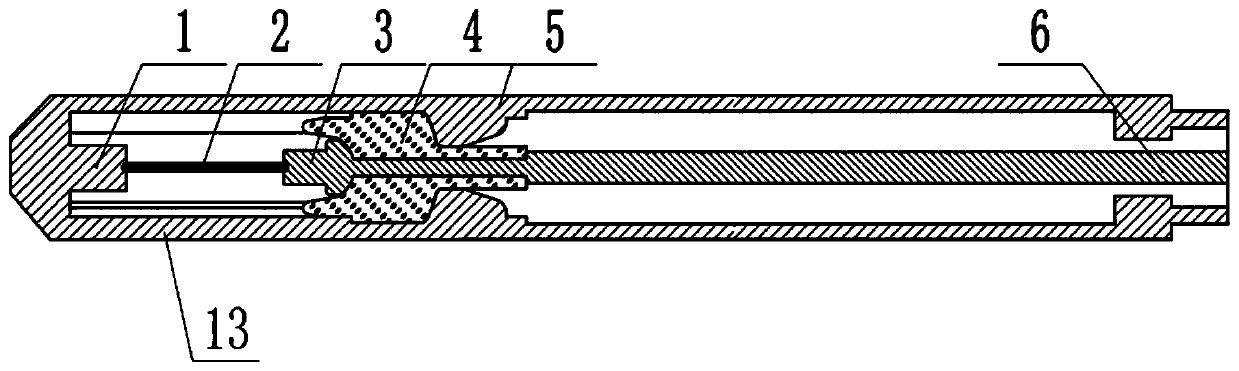

[0033] A rock pre-splitting method in a mine rock roadway driving face, comprising an energy converter 11 and an orifice device 12 .

[0034] Such as image 3 , Figure 4 As shown, the energy converter 11 includes a ground electrode 1 , a metal wire 2 , a high voltage electrode 3 , an insulating support 4 , a casing 5 , a cable interface 6 and a shock wave directional reflective arc plate 13 .

[0035] The shell 5 is a cylindrical structure, and its interior is hollow. The high-voltage electrode 3 is fixed on the end of the shell 5 through the insulating support 4. The cable at the end of the cable interface 6 passes through the body of the shell 5, the insulating support 4 and the rear end of the high-voltage electrode 3. connection, the ground electrode 1 is connected to the front end of the shell 5 through two shock wave dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com