Super-high seam coal face hydraulic fracturing coal mining method

A coal mining face and hydraulic fracturing technology, which is applied in the field of hydraulic fracturing coal seams, can solve the problems of hard-to-break coal and low recovery rate, so as to improve recovery rate, avoid blind spots, and reduce the degree of top-coal caving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: A kind of hydraulic fracturing coal mining method in coal mining face of extra-thick coal seam, please refer to Figure 1 to Figure 5 .

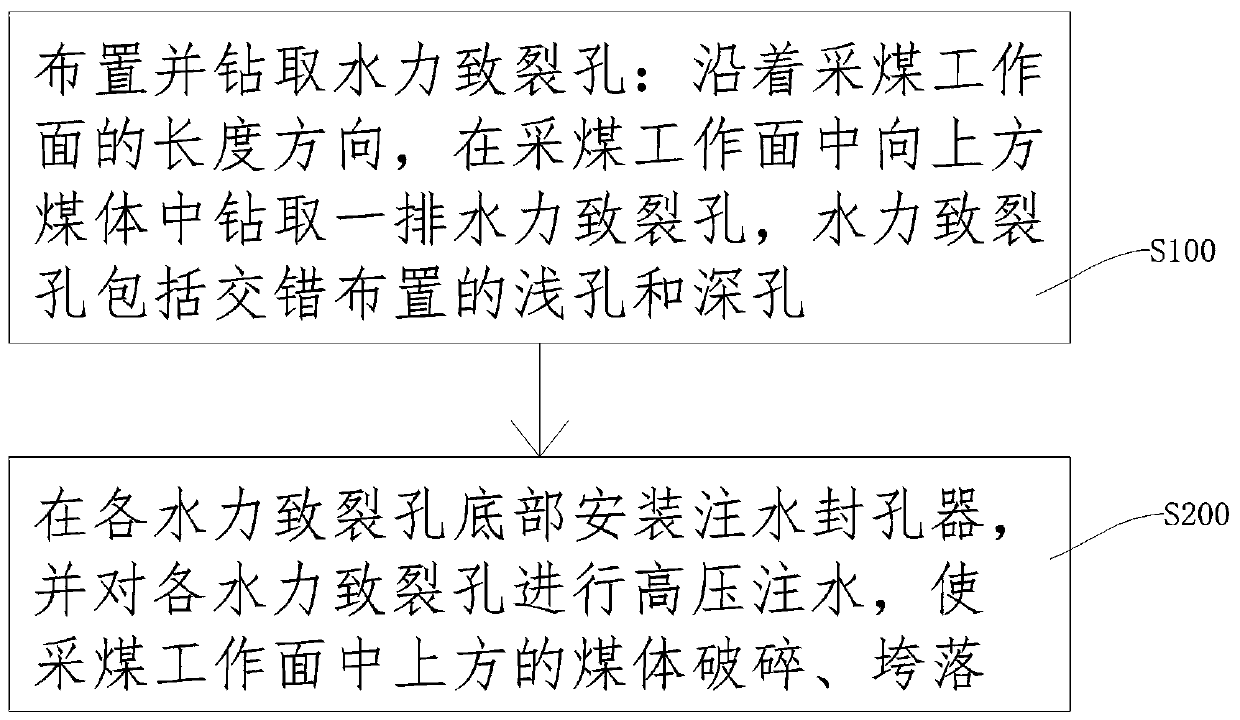

[0037] like figure 1 As shown, the hydraulic fracturing coal mining method of the ultra-thick coal seam coal mining face provided by the embodiment of the present invention includes the following steps:

[0038] S100. Arranging and drilling hydraulic fracturing holes: along the length direction of the coal mining face, drill a row of hydraulic fracturing holes in the upper coal body in the coal mining face. The hydraulic fracturing holes include shallow holes and deep holes arranged alternately. hole.

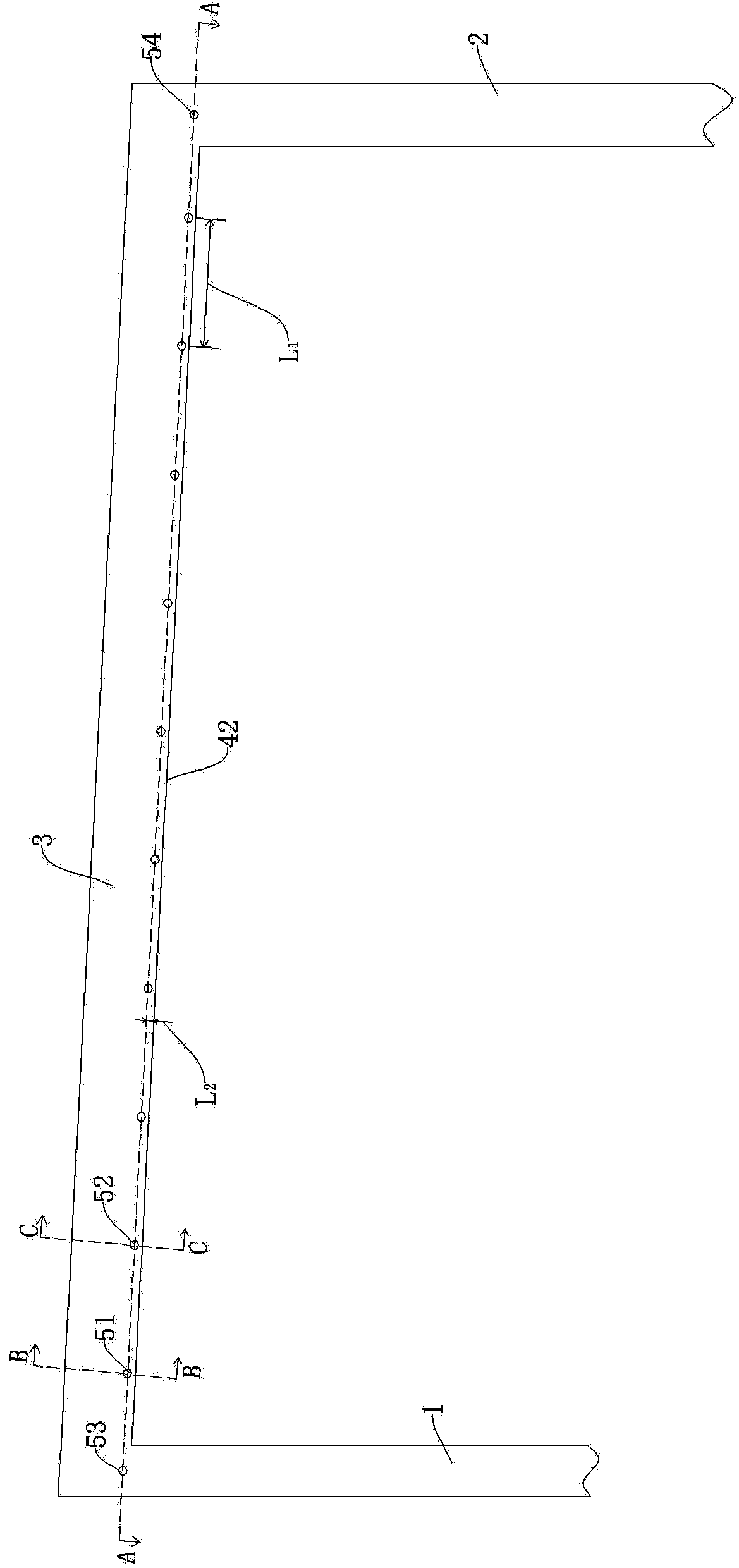

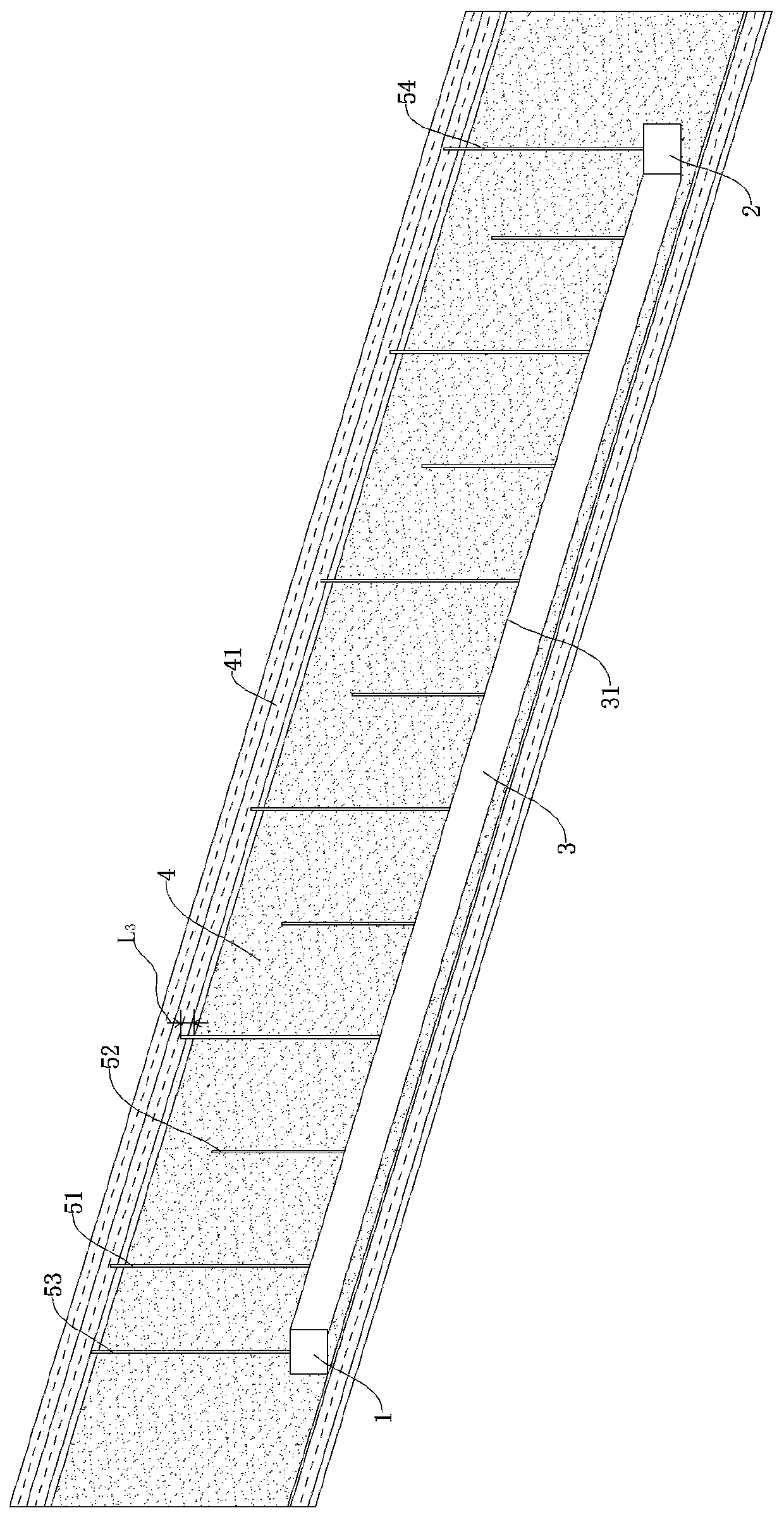

[0039] Combine below Figure 2 to Figure 5 The specific operation manner of step S100 is described.

[0040] figure 2 It shows a schematic diagram of the planar structure of a mining coal mine. Coal mining means that before coal mining, two roadways are opened from the ground to the depth of the coal mine. These two...

example

[0056] A coal mine being mined by an industrial coal mine works through comprehensive mechanization. The length of the coal mining face along the roadway (transportation chute, return air chute) is 1295m, the inclination angle of the coal mining face is 17°, and the length The coal seam has an average thickness of 130m, and the average thickness of the coal seam is 17m. The coal mining process is comprehensive mechanized top coal caving, the mining height is 3.0m, and the coal caving height is 14.03m. The relative gushing volume is 4t / m3. Here, the mining height of 3.0m refers to the height range that can be mined by the cutting head of the roadheader, and the coal setting height of 14.03m refers to the height range mined by breaking and caving the coal body at the top of the coal mining face.

[0057] At the beginning of coal mining, the coal mine used explosives to carry out advanced pre-splitting blasting of the top coal, but due to the thick coal seam and the long coal min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com