Plastering material for building wall body

A technology for building walls and plastering materials, applied in construction, building structure, covering/lining, etc., can solve the problems affecting the quality and life of buildings, increasing labor and quality hidden dangers, and increasing the alkalinity of walls, etc., to achieve The effects of improving civilized construction, increasing labor productivity, and reducing overall costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the building wall plastering material is composed of the following components: 35kg of cement, 45kg of sand and gravel, 0.2kg of water-retaining agent, 9.4kg of gypsum, 0.4kg of anti-cracking fiber, 5kg of lime calcium, and 5kg of fly ash. The agent is hydroxypropyl methylcellulose, and the crack-resistant fiber is polyacrylonitrile fiber. The specific composition is shown in Table 1.

[0027] The construction method of building wall plastering material of the present embodiment comprises:

[0028] (1) Premixing the dry powder of the building wall plastering material;

[0029] (2) Add water to the premix obtained in step (1), the mass ratio of water to building wall plastering material is: 1:2-3, and stir to obtain building wall plastering mortar;

[0030] (3) Plastering with the building wall plastering mortar obtained in step (2).

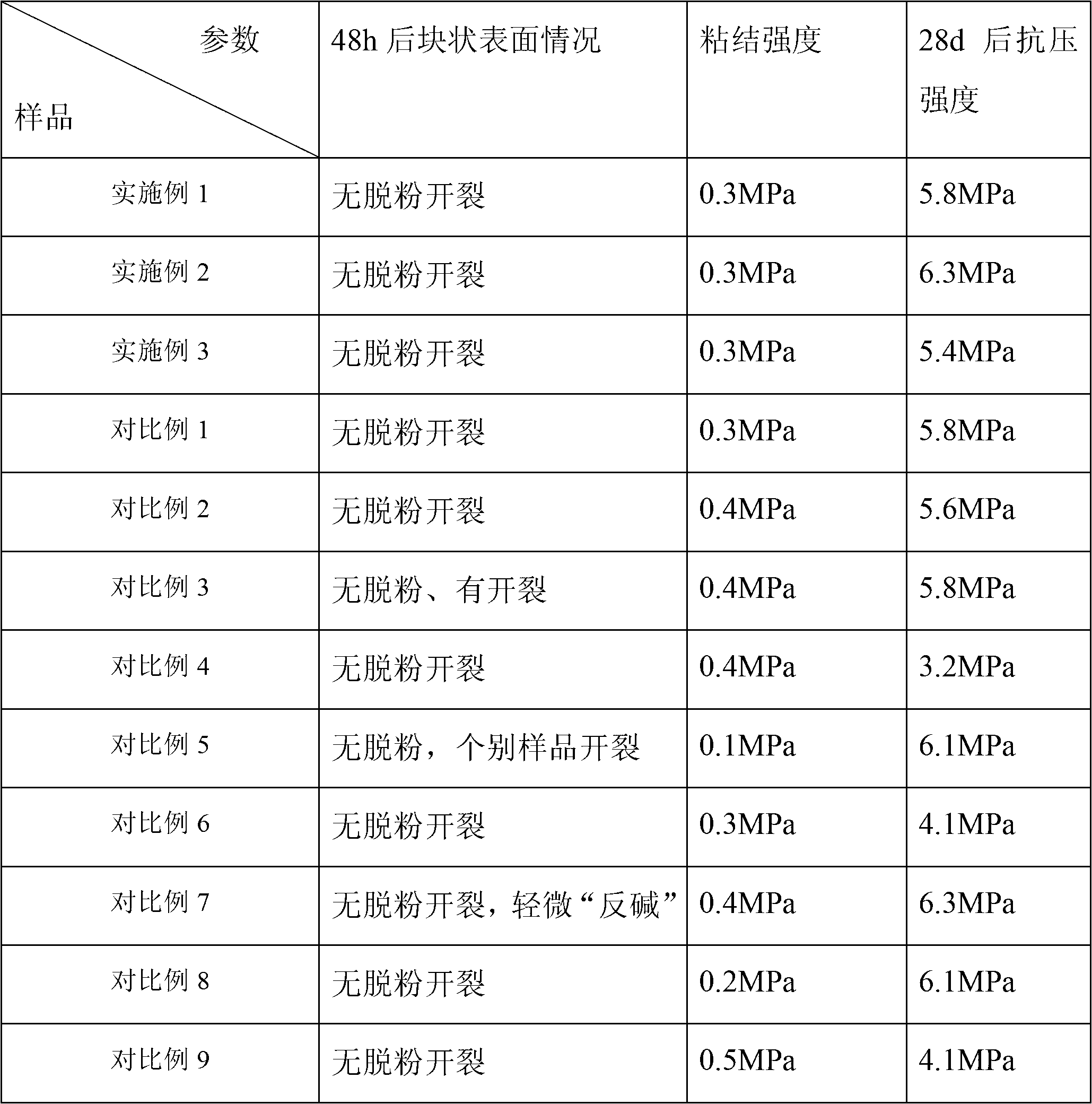

[0031] Refer to the detection method in "JGJ / T220-2010 Plastering Mortar Technical Regulations" to detect the qual...

Embodiment 2

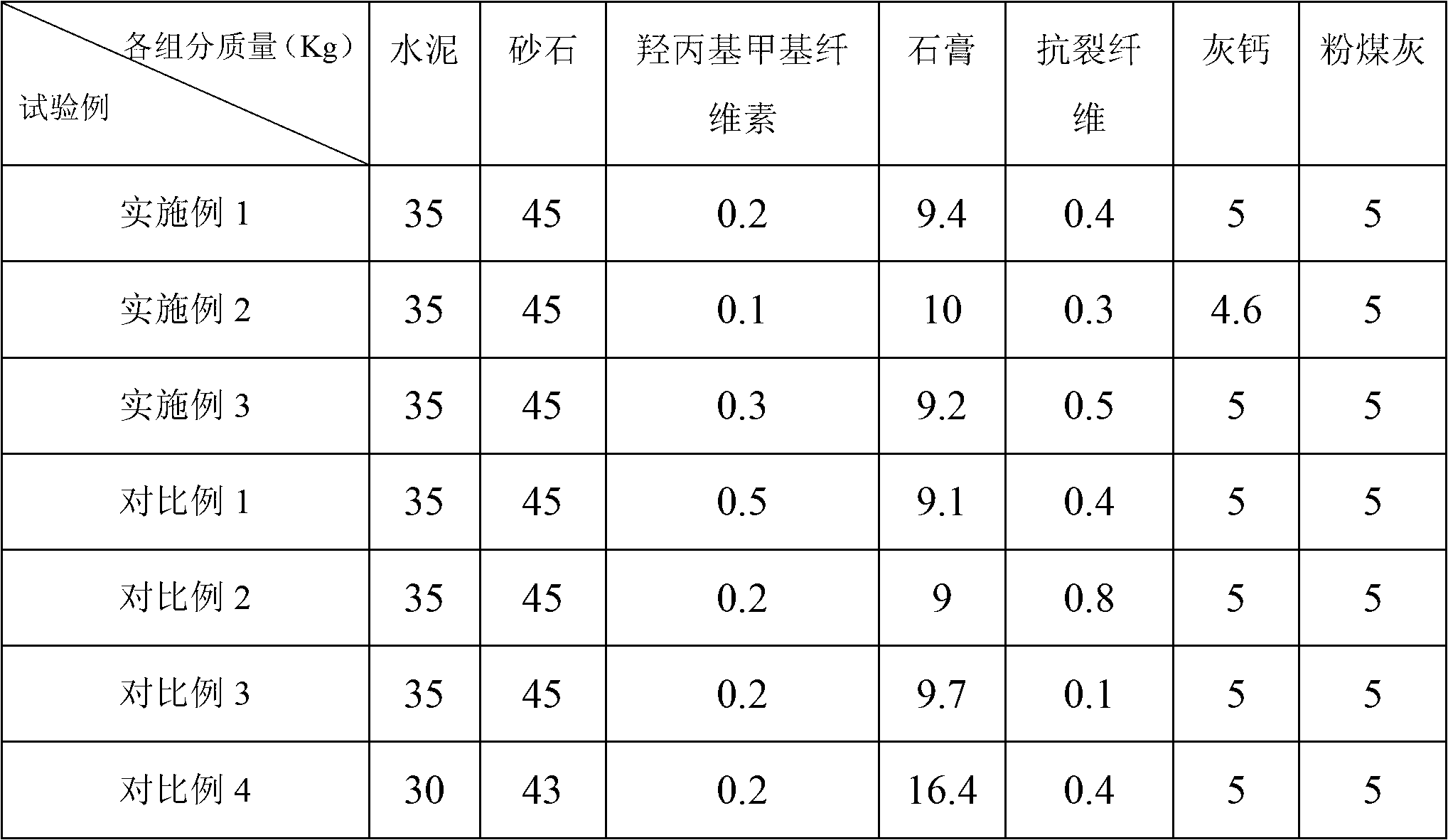

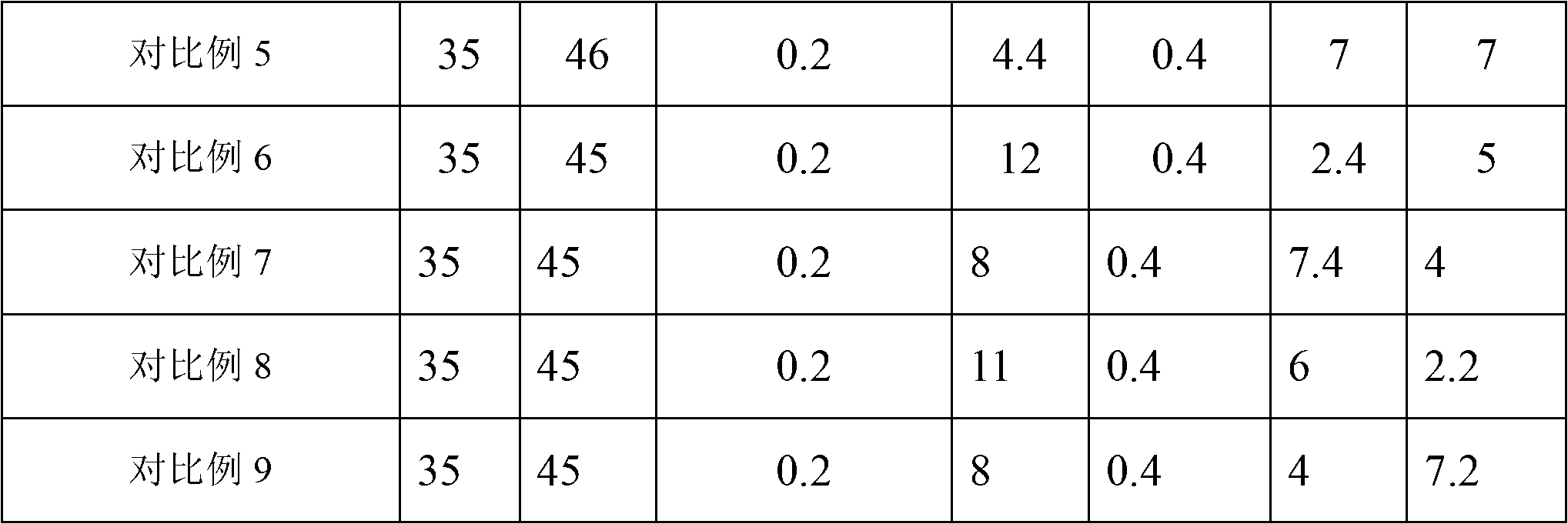

[0032] The composition ratio of embodiment 2, embodiment 3 and comparative examples 1-9 is shown in table 1, its construction method is the same as embodiment 1, and the detection method is the same as embodiment 1.

[0033] Table 1 Components of each test case

[0034]

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com