A New Titanium Alloy Composite Tube

A titanium alloy and composite pipe technology, which is applied to slender elements, building elements, layered products, etc., can solve the problems of heavy weight, poor plasticity of titanium alloys, and unfavorable market promotion, so as to ensure service life and solve problems. Processing is not easy, the effect of reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

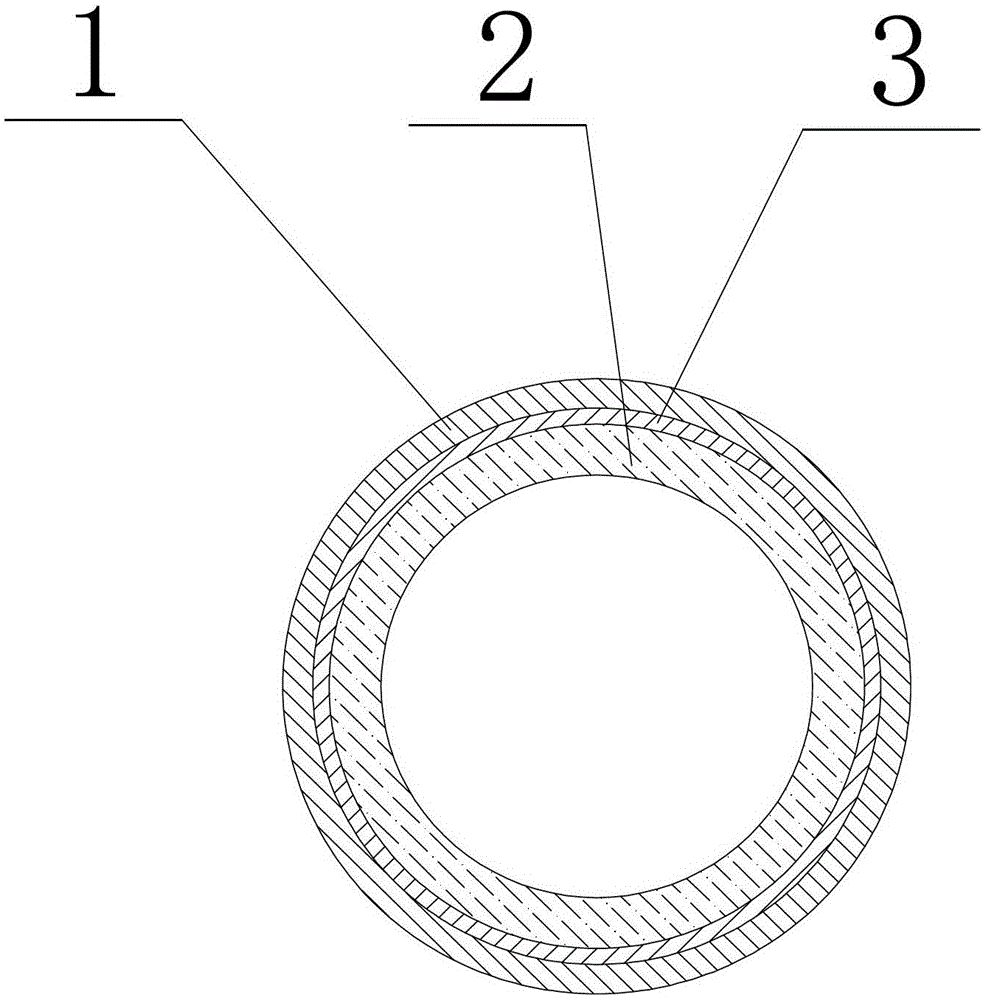

[0019] Such as figure 1 As shown, a new titanium alloy composite pipe includes a titanium alloy layer 1 and an auxiliary layer 3 , and the auxiliary layer 3 is located in the titanium alloy layer 1 . An isolation layer 3 is arranged between the titanium alloy layer 1 and the auxiliary layer 2 .

[0020] In this embodiment, the titanium alloy layer 1 is made of titanium alloy with a thickness of 0.5-2.5 cm, and the outer diameter of the titanium alloy layer is 8-12 cm.

[0021] In this embodiment, the auxiliary layer 2 is an auxiliary layer made of stainless steel. Meanwhile, the outer diameter of the auxiliary layer is 6-10 cm, and the thickness of the auxiliary layer is 1-2 cm.

[0022] In this embodiment, the isolation layer 3 is an isolation layer made of polyethylene material. The thickness of the isolation layer is 2-4cm.

[0023] In order to better achieve the predetermined effect, the cross-sectional shape of the titanium alloy layer 1 and the auxiliary layer 3 is ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com