Hybrid latex comprising polymeric particles having core-shell structure and its preparation method

A technology of polymer particles and latex, which can be used in building construction, roofs using flexible materials, roof coverings, etc., and can solve problems such as increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

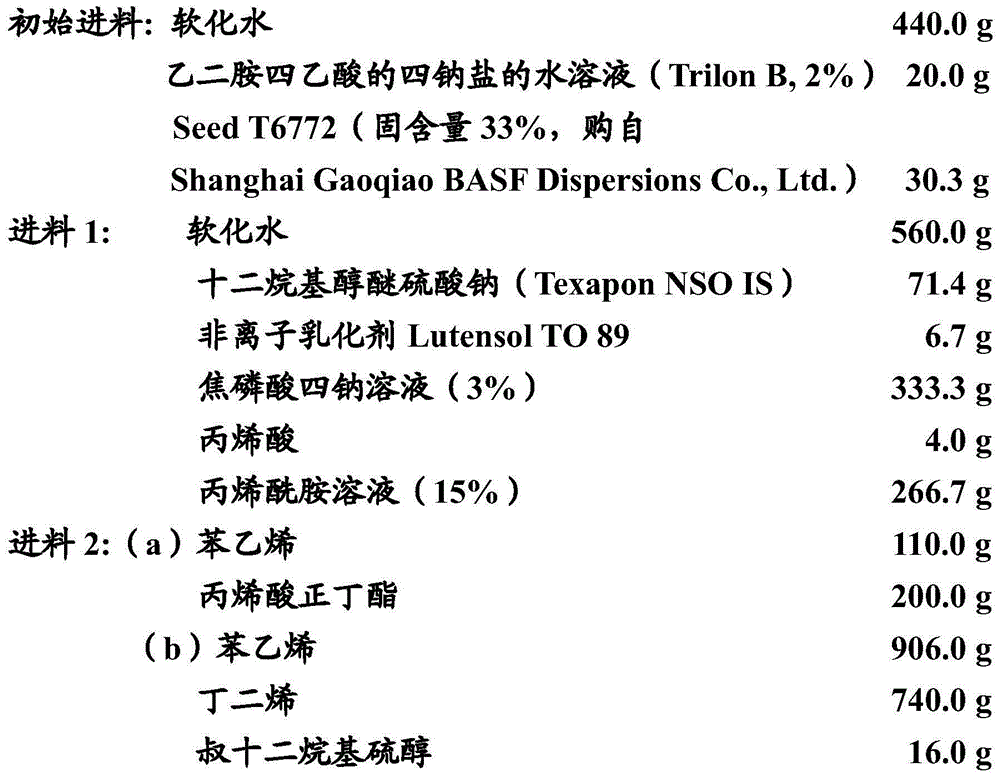

Embodiment 1

[0041]

[0042]Under nitrogen, the initial charge was added to the stainless steel reactor with stirring (200 rpm). When the temperature in the reactor reached 70-90° C., 28.6 g of sodium persulfate solution (7%) were added within 5 minutes. Then feed 1, 200 g of sodium persulfate solution (7%) and feed 2 were added dropwise simultaneously and the addition time was 3-6 hours, wherein feed 2 was divided into two parts (a) and (b) dropwise Add, and first add part (a) dropwise and then add part (b) dropwise. After complete addition, the mixture was incubated at 70-90°C for 1-2 hours for post-polymerization. Then the mixture was cooled to 65-85° C., and 62.0 g of tert-butyl hydroperoxide solution (10%) and 69.2 g of acetone sodium bisulfite solution (13%) were added dropwise simultaneously and reacted for 1-3 hours. Then 60.0 g of sodium hydroxide solution (10%) were added under slow stirring, and the resulting mixture was cooled to room temperature, and 13.3 g of the fungici...

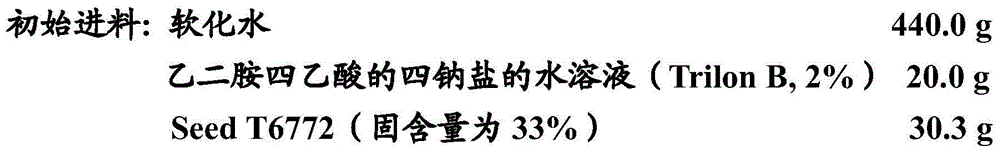

Embodiment 2

[0044]

[0045]

[0046] Under nitrogen, the initial charge was added to the stainless steel reactor with stirring (200 rpm). When the temperature in the reactor reached 70-90° C., 28.6 g of sodium persulfate solution (7%) were added within 5 minutes. Then feed 1, 200 g of sodium persulfate solution (7%) and feed 2 were added dropwise simultaneously and the addition time was 3-6 hours, wherein feed 2 was divided into two parts (a) and (b) dropwise Add, and first add part (a) dropwise, then add part (b) dropwise. After complete addition, the mixture was incubated at 70-90°C for 1-2 hours for post-polymerization. Then the mixture was cooled to 65-85° C., and 62.0 g of tert-butyl hydroperoxide solution (10%) and 69.2 g of acetone sodium bisulfite solution (13%) were added dropwise simultaneously and reacted for 1-3 hours. Then 60.0 g of sodium hydroxide solution (10%) were added under slow stirring, and the resulting mixture was cooled to room temperature, and 13.3 g of t...

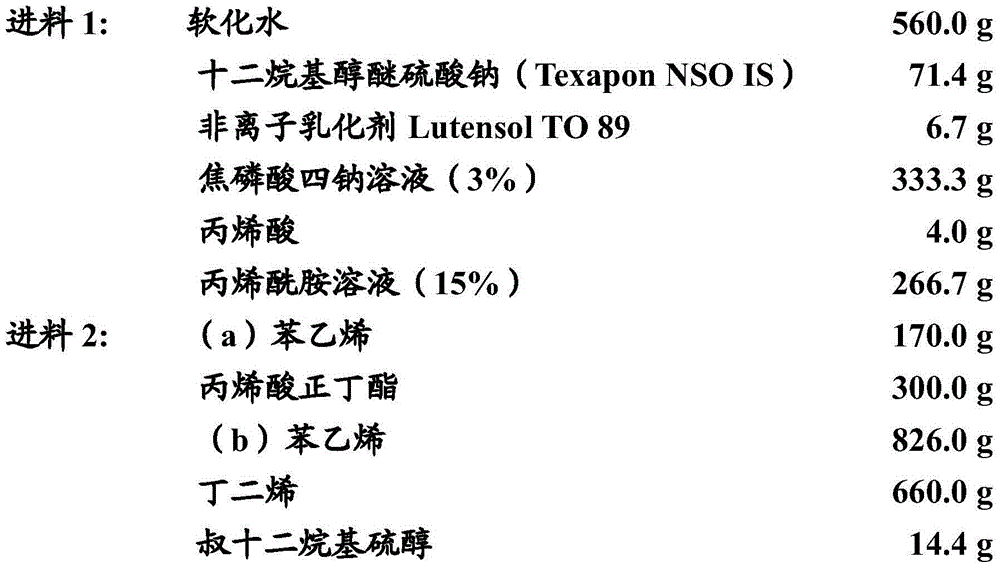

Embodiment 3

[0048]

[0049]

[0050] Under nitrogen, the initial charge was added to the stainless steel reactor with stirring (200 rpm). When the temperature in the reactor reached 70-90° C., 28.6 g of sodium persulfate solution (7%) were added within 5 minutes. Then feed 1, 200 g of sodium persulfate solution (7%) and feed 2 were added dropwise simultaneously and the addition time was 3-6 hours, wherein feed 2 was divided into two parts (a) and (b) dropwise Add, and first add part (a) dropwise, then add part (b) dropwise. After complete addition, the mixture was incubated at 70-90°C for 1-2 hours for post-polymerization. Then the mixture was cooled to 65-85° C., and 62.0 g of tert-butyl hydroperoxide solution (10%) and 69.2 g of acetone sodium bisulfite solution (13%) were added dropwise simultaneously and reacted for 1-3 hours. Then 60.0 g of sodium hydroxide solution (10%) were added under slow stirring, and the resulting mixture was cooled to room temperature, and 13.3 g of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com