Micron gold cage shell structure material with broadband absorption characteristic and preparation method of micron gold cage shell structure material

A technology of absorption characteristics and shell structure, which is applied in the field of micron gold cage shell structure materials and its preparation, can solve the problems of inability to realize broadband absorption, and achieve the effects of adjustable shell structure, adjustable thickness, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

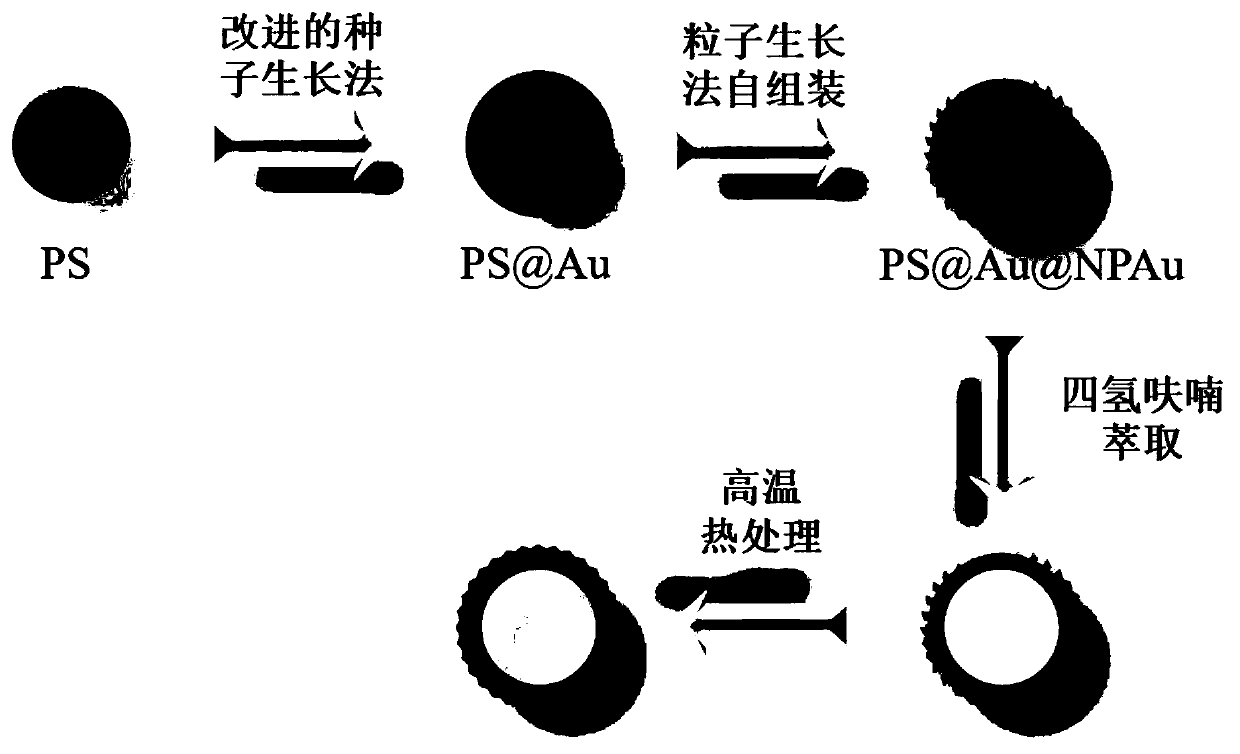

[0038] A kind of preparation method of the micron gold cage shell structure material with broadband absorption characteristic provided by the present invention comprises the following steps:

[0039](1) Obtain the emulsion of polystyrene microspheres with a gold shell on the surface, which is denoted as PS@Au microsphere emulsion; the emulsion contains PS@Au microspheres with a core-shell structure, which is based on polystyrene microspheres Core, with the dense gold film on the surface of the polystyrene microsphere as the shell;

[0040] (2) Modify the PS@Au microsphere emulsion so that its surface is charged, and obtain the modified PS@Au microsphere emulsion;

[0041] (3) Mix the nano-gold concentrate with the modified PS@Au microsphere emulsion, so that the nano-gold particles are attached to the surface of the PS@Au microspheres through electrostatic interaction, and obtain monodisperse gold nanoparticles-coated PS @Au microspheres; the microspheres use PS@Au microspher...

Embodiment 1

[0069] figure 1 It is a flow chart of the method for coating PS@Au with nano-gold particle foam of the present invention, which specifically includes the following steps:

[0070] Step 1. Preparation of nano-gold particle concentrate

[0071] (1) Add 1mL of tetrachloroauric acid solution with a mass fraction of 1% and 79mL of ultrapure water in the ground-mouth Erlenmeyer flask A, and stir in a water bath magnetic stirrer (temperature is 60° C.);

[0072] (2) Add 4 mL of 1% sodium citrate solution and 200 μL of 0.1 moL / L potassium carbonate solution into Erlenmeyer flask B. Then add 700 μL of tannic acid solution with a mass fraction of 1% and 15.1 mL of ultrapure water mixed solution, put it in a constant temperature magnetic stirring water bath (temperature is 65° C.) and preheat and stir for 5 minutes;

[0073] (3) Quickly add the solution of Erlenmeyer flask B into Erlenmeyer flask A, and then stir at constant temperature in a water-bath magnetic stirrer for 30 minutes t...

Embodiment 2- Embodiment 6

[0103] Other conditions are the same as in Example 1, and the parameter tables in the preparation of PS@Au emulsion involved in Examples 2 to 6 and the preparation process of nano-gold concentrate are shown in Table 1 and Table 2, and the parameter ranges in Table 1 and Table 2 are adopted. Nano-gold particles coated PS@Au composite materials can obtain PS@Au coated with nano-gold particles foam.

[0104] Table 1: Parameter table of polystyrene microsphere emulsion

[0105]

[0106]

[0107] Table 2: Parameter table of gold nanoparticles with different particle sizes (each parameter of embodiment 4 to embodiment 6 is the same as embodiment 1)

[0108]

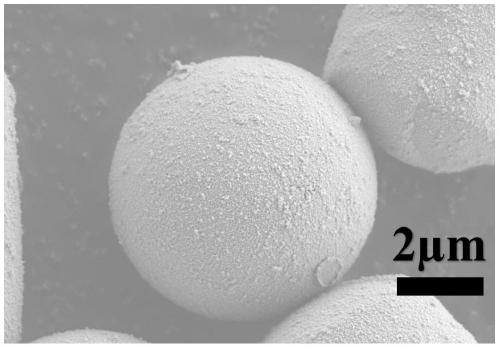

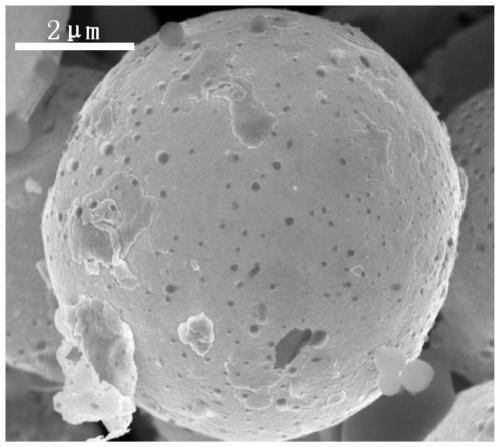

[0109] figure 2 The transmission electron microscope image of the micron gold cage shell prepared for Example 1 of the present invention shows the nano-gold shell layer on the surface and the monodisperse gold nano-particles attached thereto.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com