Ignition and stable combustion device for industrial gas burner

A technology of stabilizing combustion device and industrial gas, which is applied in combustion ignition, gas fuel burners, burners, etc., can solve the problem of insufficient ignition flame stability, and achieve the effect of reducing NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

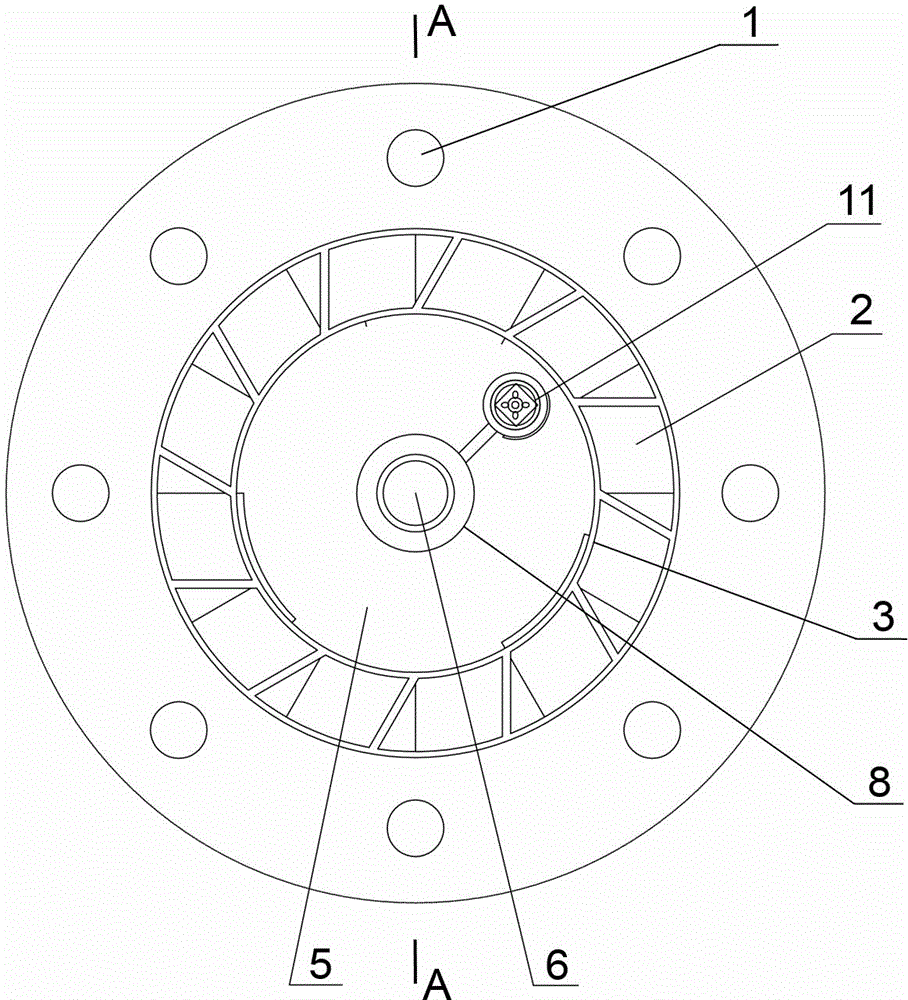

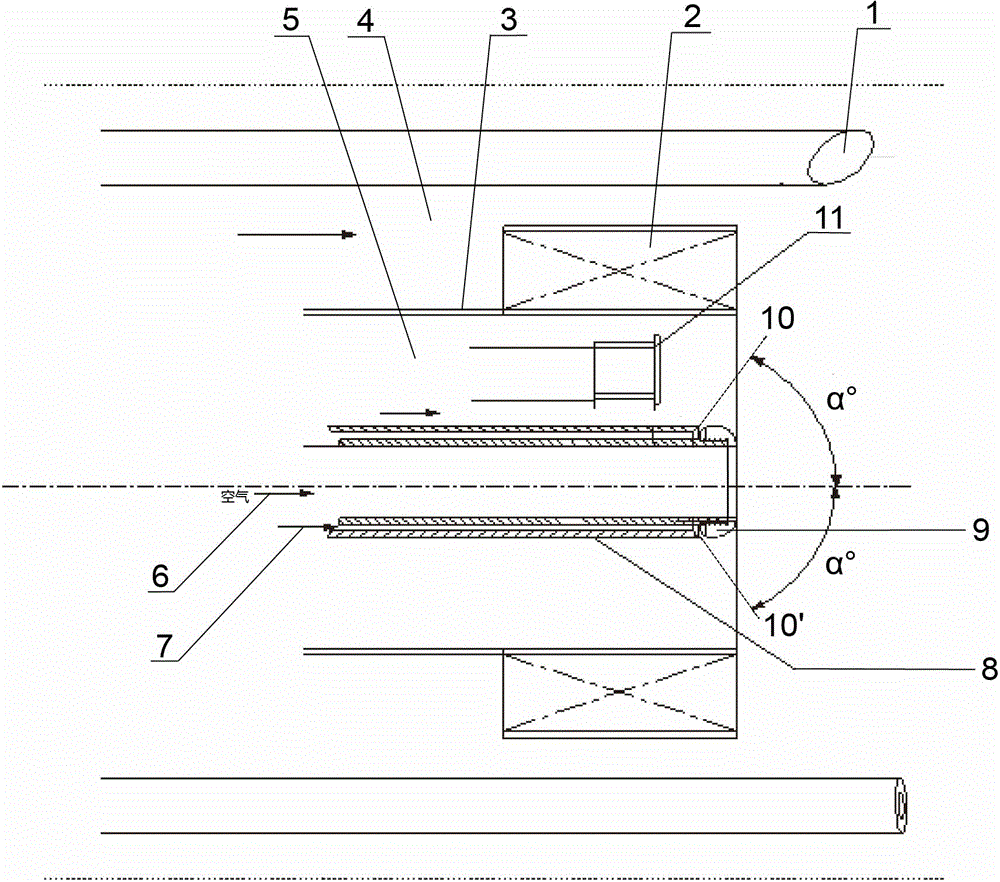

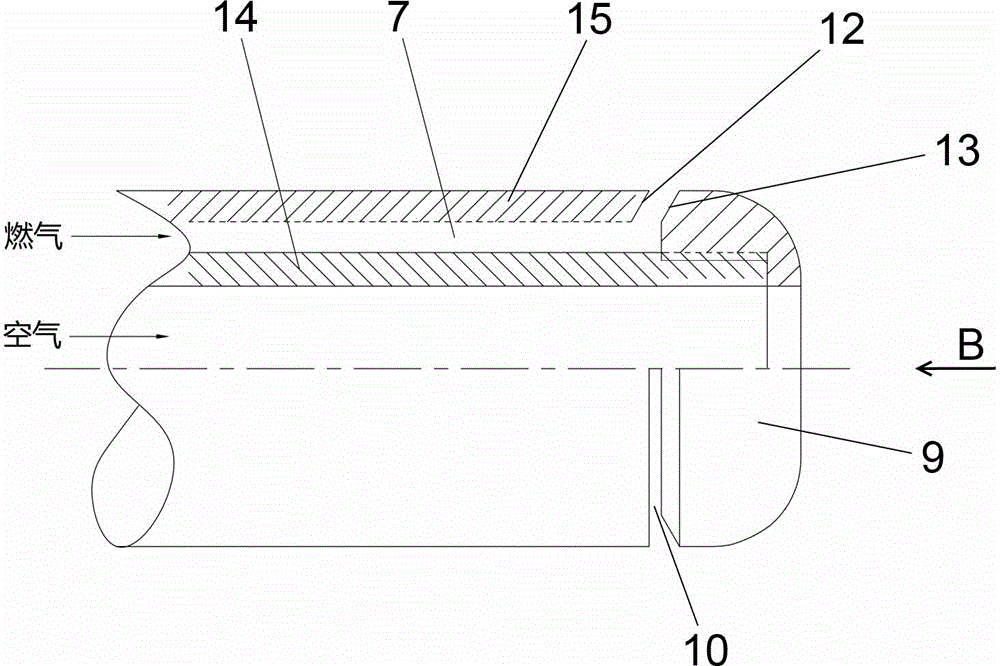

[0014] figure 1 and figure 2 It is a schematic diagram of the structure of the present invention. As can be seen from the figure, an industrial gas burner ignition and stable combustion device of the present invention includes a central tube 8, a central tube 3, a swirler 2, an ignition gun 11 and a main gas gun 1, and is characterized in that: the central tube 8 includes Central tube inner tube 14 and central tube outer tube 15, said central tube inner tube 14 is placed in said central tube outer tube 15, and coaxially arranged, said central tube inner tube 14 and said central tube outer tube 15 are The gas inlet channel 7 of the central annular gas injection device, the upper end of the gas inlet channel 7 of the central annular gas injection device is blocked by an annular gas channel cover 9, and the inner periphery of the annular gas channel cover 9 is in contact with the The central tube inner tube 14 upper end is fixedly connected, by image 3 and Figure 4 It can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com