Matched arrangement structure of vertical groove type bulkhead and in-pier partition plate

A technology for arranging structures and vertical grooves, applied in the direction of hull bulkheads, ship accessories, transportation and packaging, etc., can solve the problems of inconvenient construction, stress concentration on the top plate of the bottom pier and the bottom plate of the top pier, etc., to reduce the increase in plate thickness, The effect of reducing the weight of structural steel and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 is arranged on the top of the vertical trough bulkhead; embodiment 2 is arranged on the bottom of the vertical trough bulkhead. The difference between embodiment 1 and embodiment 2 lies in the different positions of the vertical trough bulkhead, and their own structures are the same, therefore, the same components use the same reference numerals.

[0024] Example 1

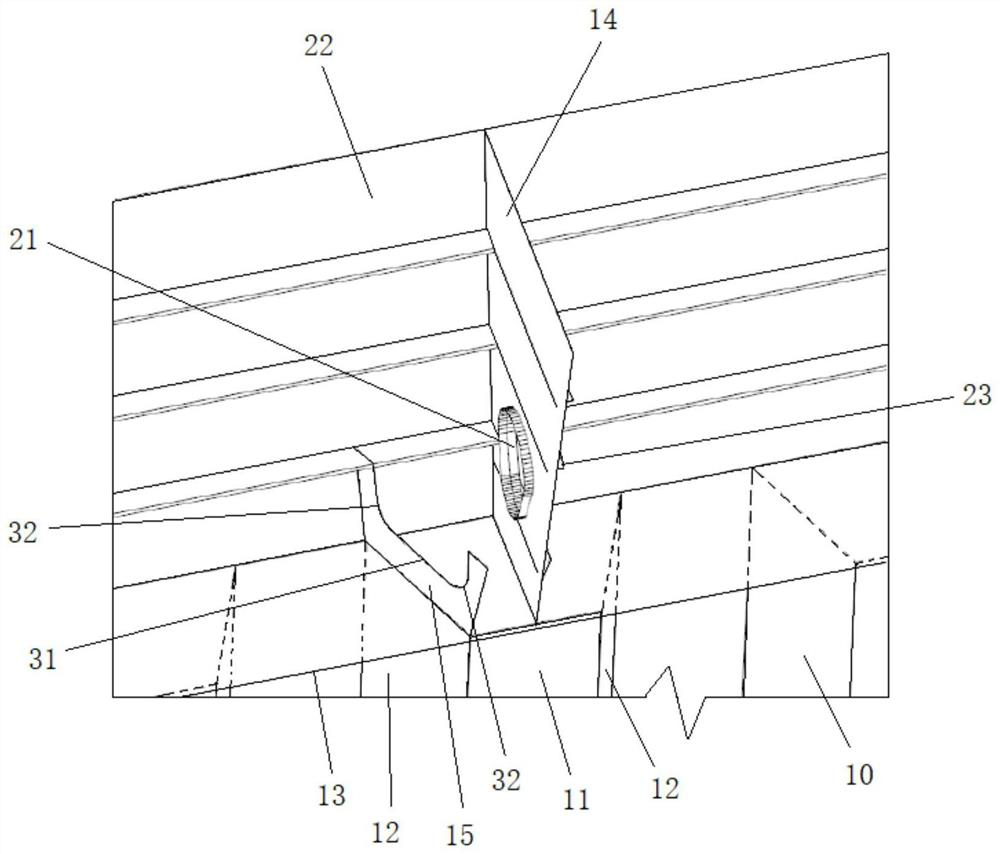

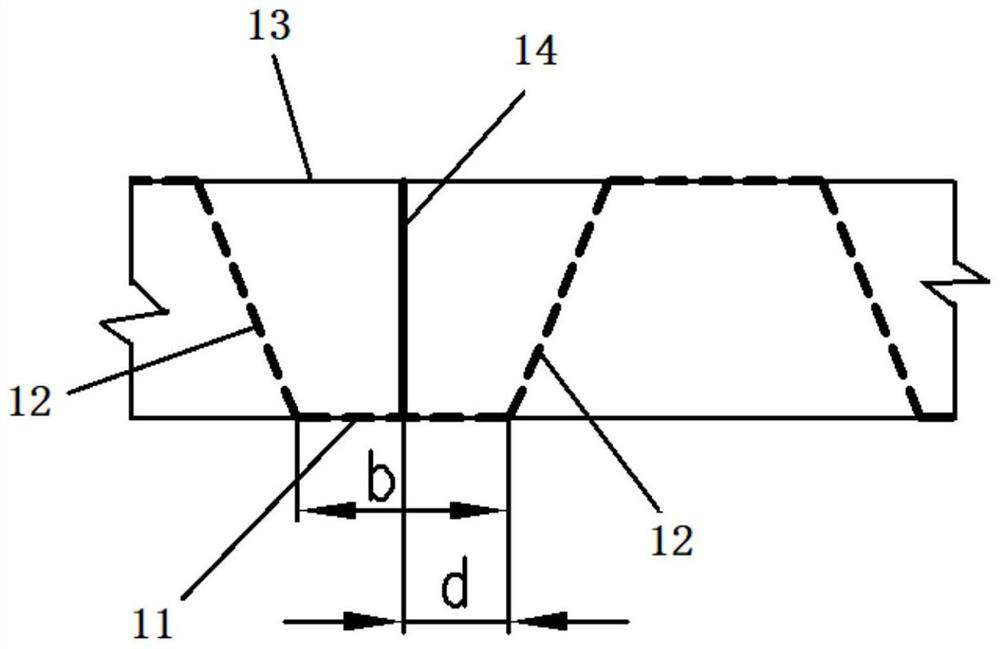

[0025] Such as figure 1 and figure 2 As shown, a vertical grooved bulkhead and pier internal partitions are arranged together, which is arranged at the end of the vertical grooved bulkhead 10; the vertical grooved bulkhead 10 includes a panel 11; the left and right sides of the panel 11 Each web 12 is provided, and the panel 11 and the two webs 12 enclose a groove.

[0026] The end of the vertical grooved bulkhead 10 is fixed with a coaming plate 13 for sealing the port of the groove; the coaming plate 13 is distributed laterally;

[0027] A partition 14 and a reinforcement plate 15 are fi...

Embodiment 2

[0043] Compared with Embodiment 1, this embodiment differs only in that it is located at different positions on the vertical trough bulkhead, and its own structure is the same, so the same components use the same reference numerals.

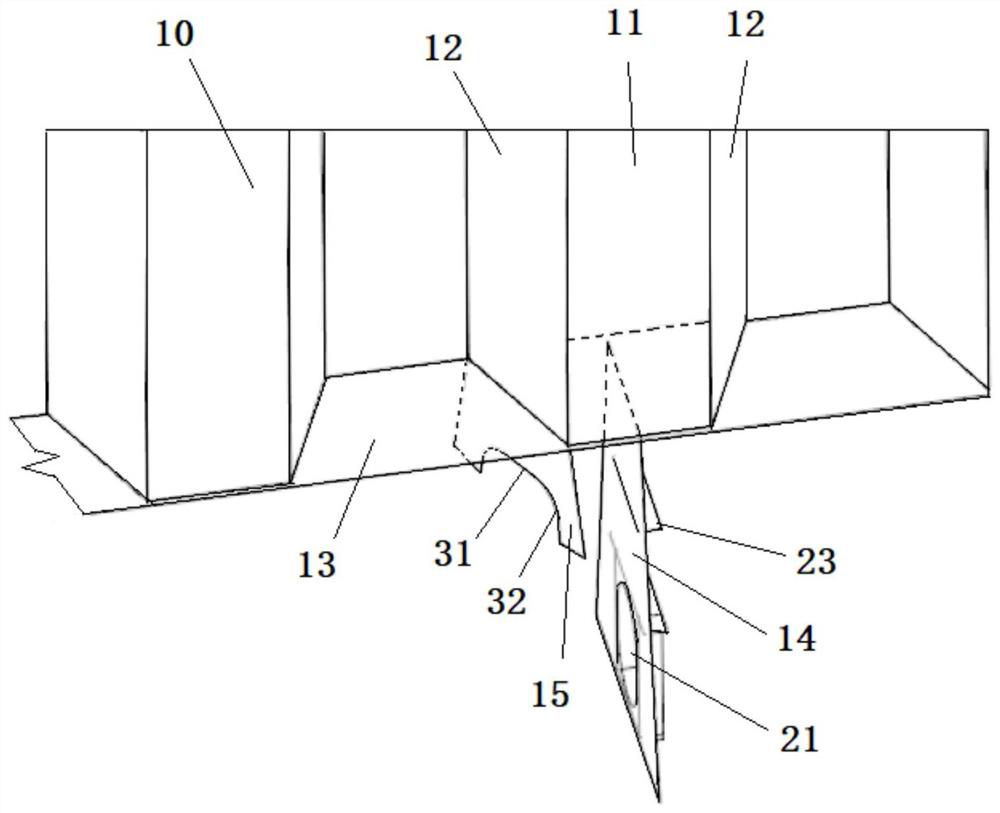

[0044] Such as image 3 As shown, the coaming plate 13, the partition plate 14 and the reinforcing plate 15 are all arranged below the vertical groove bulkhead 10; the coaming plate 13 is the bottom pier top plate; the partition plate 14 is the bottom pier partition. exist image 3 , the side panels are not shown. image 3 In , only one reinforcing plate 15 is shown. In order to clearly show the structure of other components, another reinforcement plate is image 3 not shown in .

[0045] The bulkheads and stiffeners are on one side of the coaming, and the face plates and webs are on the other side of the coaming. Specifically, bulkheads and stiffeners are located below the coaming, and panels and webs are located above the coaming.

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com