Filling system for coating production

A filling system and coating technology, applied in packaging, bottle filling, liquid bottling, etc., can solve problems affecting filling, splashing of coating liquid, lack of positioning structure, etc., to improve position stability and avoid accidental dumping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

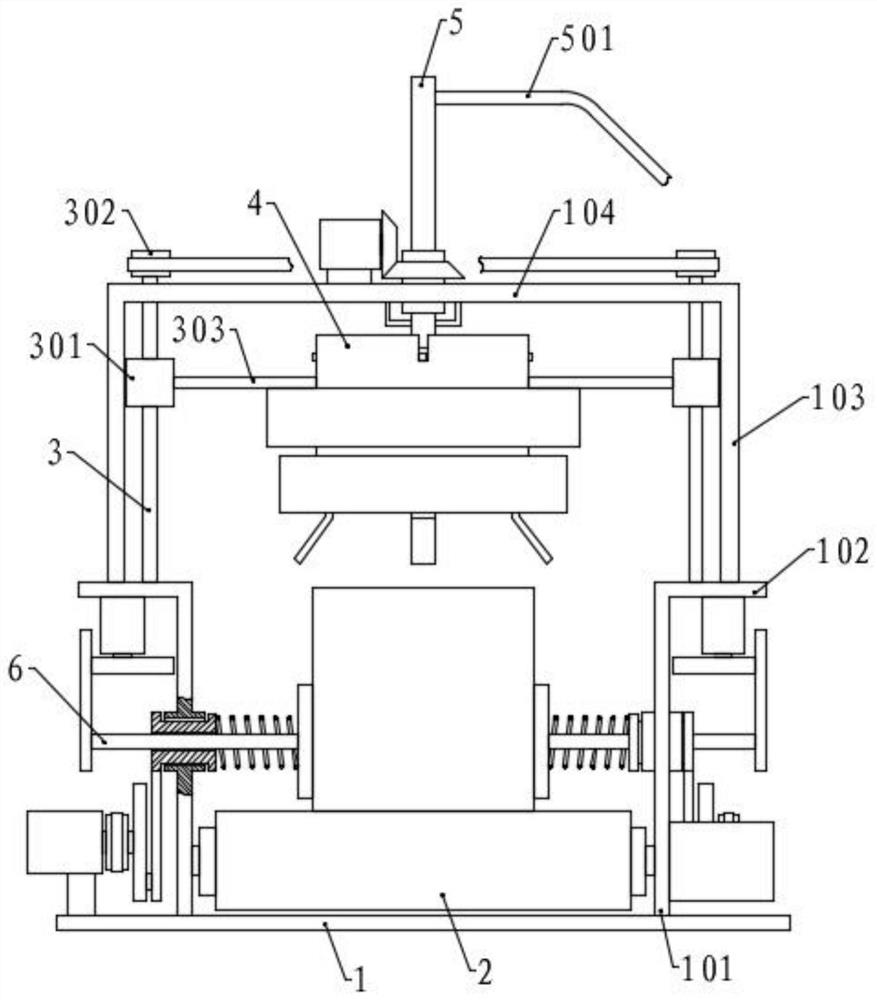

[0050] Please refer to the accompanying drawings, the present invention provides a technical solution: a filling system for paint production, including a base 1, two vertical first side plates 101 are symmetrically fixed on both sides of the top surface of the base 1, the first The top outside of the side plate 101 is fixed with a first horizontal plate 102, the outer end of the first horizontal plate 102 is fixed with a vertical second side plate 103, and a second horizontal plate 103 is fixed between the tops of the two second side plates 103. Horizontal plate 104;

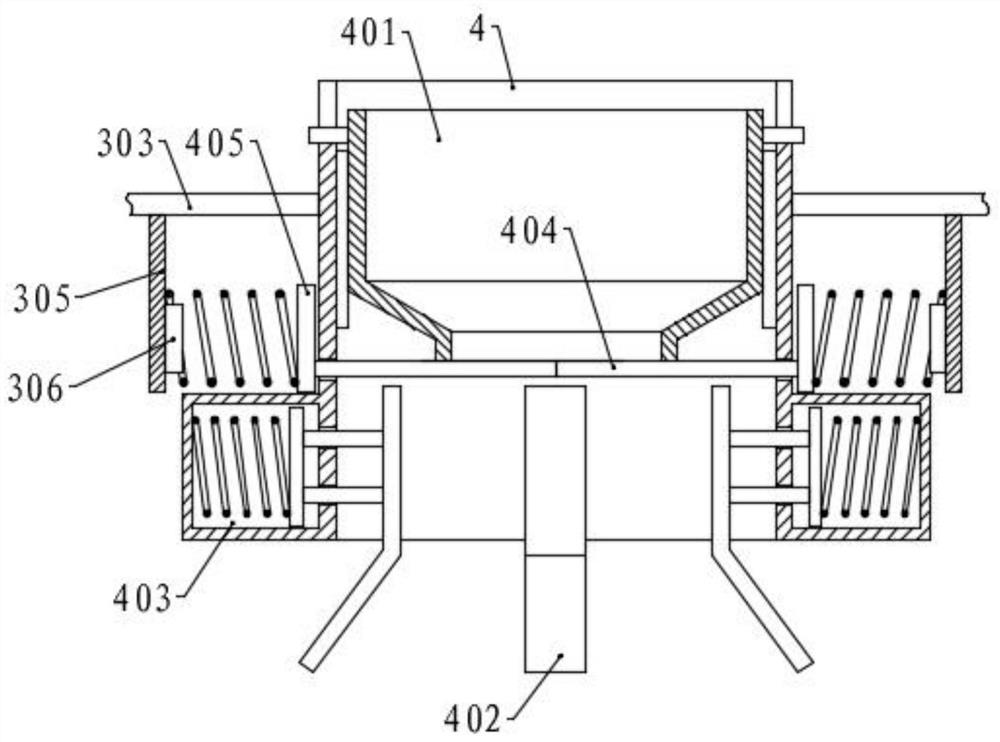

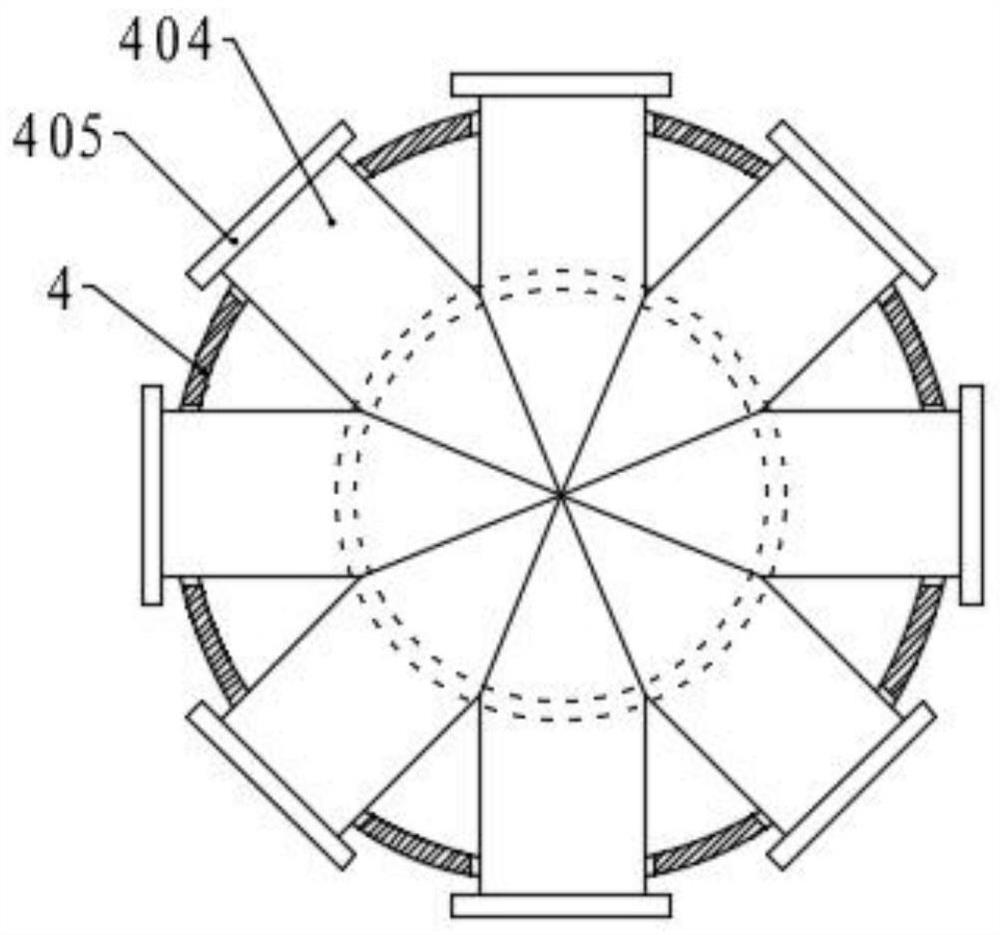

[0051] A conveying assembly is provided between the bottoms of the two first side plates 101, a lifting assembly is provided on the inner side of the second side plate 103, and a lifting cylinder 4 is connected between the two lifting assemblies, and the middle of the second horizontal plate 104 is provided with a lifting assembly. With filling components;

[0052] The conveying assembly includes a conveying be...

Embodiment 2

[0061] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the upper part of the first side plate 101 is provided with a positioning assembly 6, and the positioning assembly 6 includes a sliding plate 606 located outside the first side plate 101, the sliding plate 606 Three sliding blocks 607 are fixed along the length direction on the inner surface, and the bottom of the sliding plate 606 is connected with a drive assembly in the middle, and a sliding slot 105 is horizontally arranged in the middle of the first side plate 101. The three sliding blocks 607 are slidably connected in the sliding slot 105 , and the inner side protrudes from the chute 105, and the limiting plate is fixed. The inner side of the sliding block 607 is connected with a positioning plate 601 through a spring. The outer end of the outer end passes through the corresponding sliding block 607 and protrudes, and the extended ends of the three positioning rod...

Embodiment 3

[0067] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that the second pulley 604 is coaxially fixed on the two rotating disks 605, and a third belt is connected to one side of the second pulley 604 through a transmission link. The drive shaft is fixed at the center of the third pulley, and the drive shafts on both sides rotate with the first side plate 101 on the corresponding side and are coaxially fixed. Through the drive shaft, the second pulley 604 and the third pulley The transmission makes the drive components on both sides move synchronously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com