Automatic centering mechanism of sensor

An automatic centering and sensor technology, applied in the direction of instruments, measuring devices, measuring force, etc., can solve the problem of inconvenient crane movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

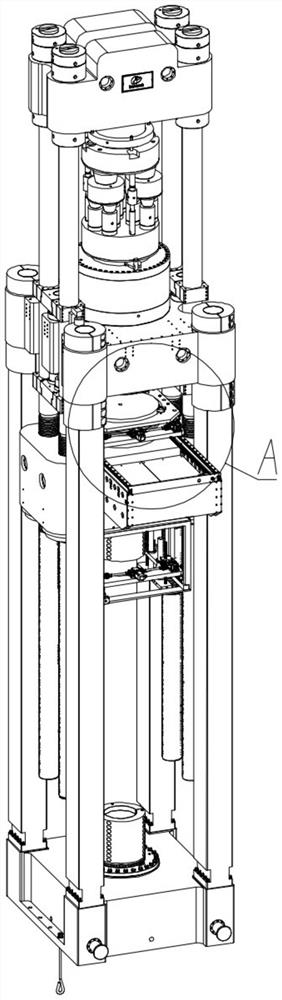

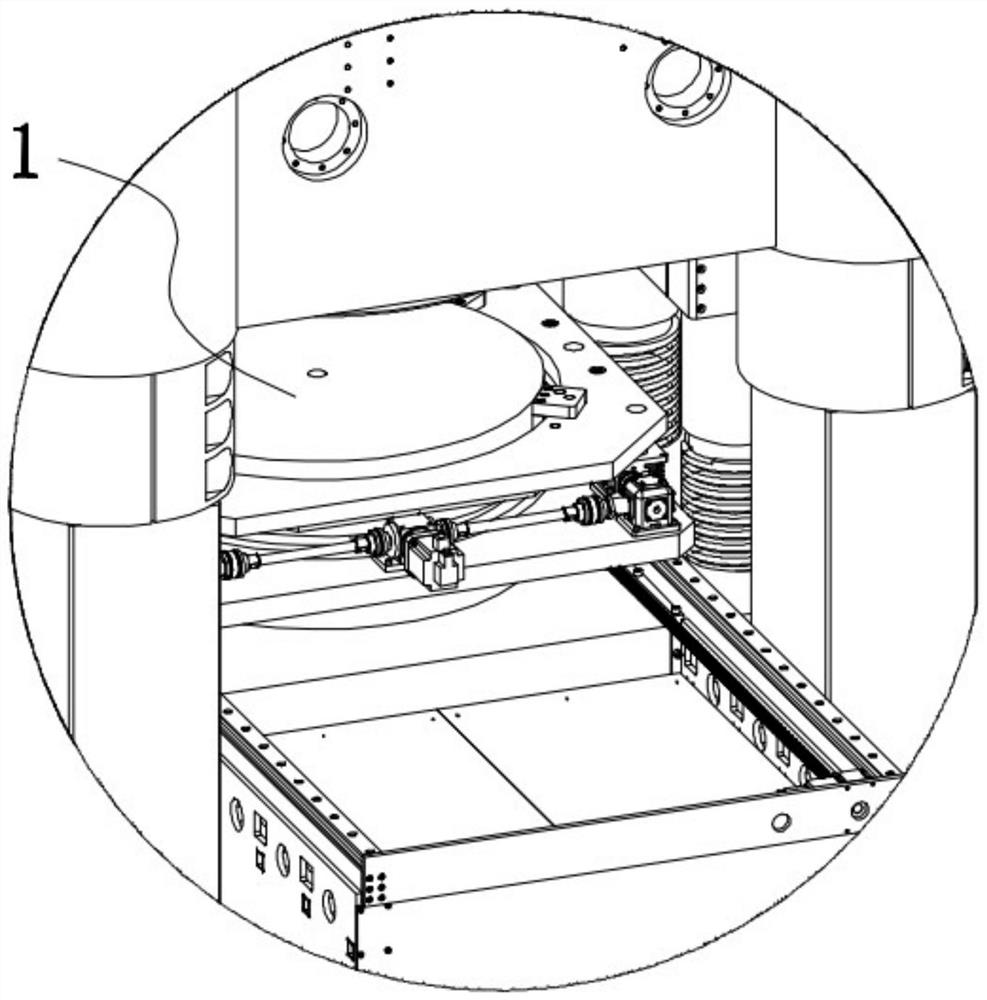

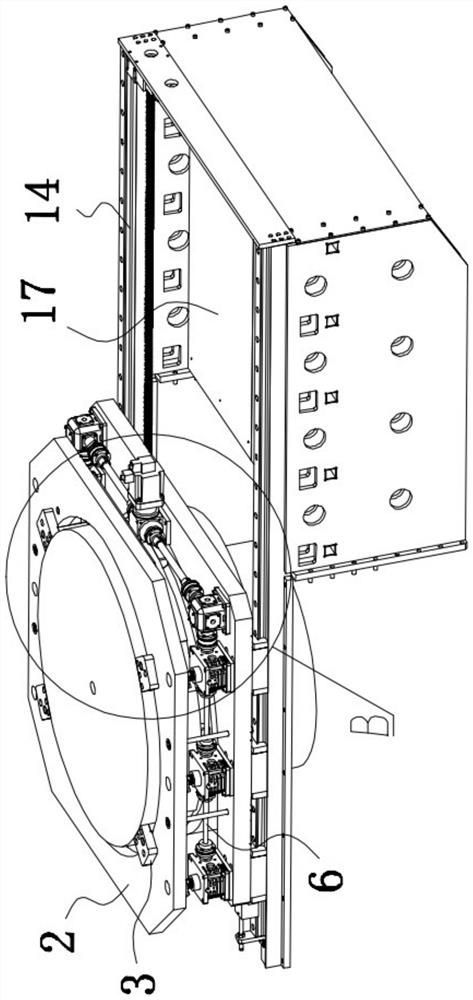

[0037] In order to achieve the purpose of the present invention, an automatic centering mechanism of a sensor includes: a supporting mechanism, including a tray 1 and a support ring 2 located on the outer circle of the tray 1, and a corner code 3 located above the support ring 2 is fixed on the edge of the tray 1 , the vertical projection of the corner code 3 intersects with the support ring 2, and the upper surface of the tray 1 is always in contact with the sensor; there is a lower pressure plate 18 with a fixed spatial position under the tray 1; the lifting mechanism, the support ring 2 vertically runs through several screws Column 8, several studs 8 are symmetrically arranged along the mirror surface, a horizontal longitudinal transmission rod 6 is connected under the studs 8 on each side, and a horizontal transmission rod 5 is connected to one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com