A method for preparing high-precision silver electrodes by sidewall protection process

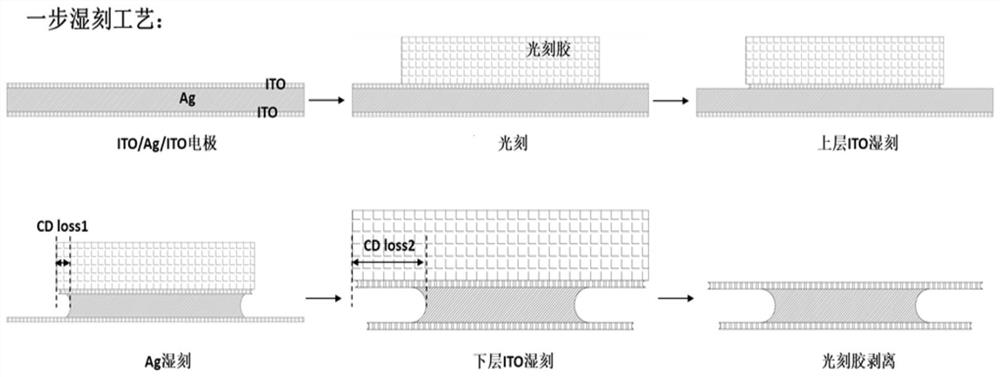

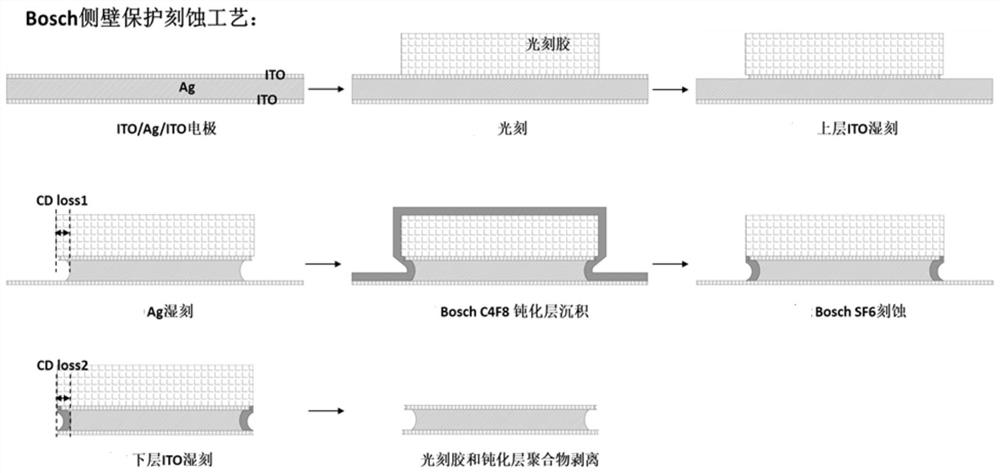

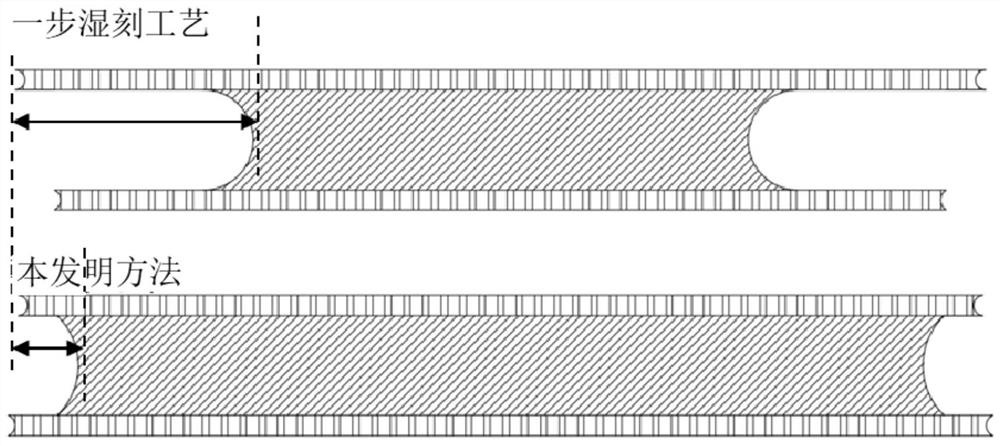

A sidewall protection, high-precision technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of large AgCDloss, poor aluminum conductivity, poor surface flatness, etc., and achieve the effect of reducing CDloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing high-precision silver electrodes by sidewall protection process, comprising the following steps:

[0035] 1), ITO / Ag / ITO structure is a three-layer sandwich structure, from bottom to top for ITO layer, Ag layer and ITO layer, and its thickness is 100A, 1000A, 100A from bottom to top; Lithography is carried out first, PR thickness is 1μm, curing energy is 50mj;

[0036] 2), then for the upper LAYER ITO that is not protected by photoresist, 8wt% oxalic acid etching is used, the upper ITO is removed in 20s, and then the Ag layer is hyged with nitric acid / phosphoric acid / acetate mixture for 10s to remove the Ag layer; The nitric acid / phosphoric acid / acetic acid mixture used has a mass fraction ratio of 20%:40%:40%.

[0037] 3) Perform C again 4 F 8 Deposition passivation layer, process parameters: time 10s, power supply power 300W, C 4 F 8Flow rate 10sccm, pressure 5mt, temperature 50 °C; The protective polymer used to form the sidewall is deposited C on ...

Embodiment 2

[0043] A method for preparing high-precision silver electrodes by sidewall protection process, comprising the following steps:

[0044] 1), ITO / Ag / ITO structure is a three-layer sandwich structure, and its thickness is 500A, 5000A, 500A; Perform lithography, PR thickness 2 μm, curing energy 500 mj;

[0045] 2), the position that is not protected by the photoresist removes the upper ITO, and the 4wt% oxalic acid wet engraving 50s is used to remove the upper ITO; Then carry out Ag wet etching, nitric acid / phosphoric acid / acetate mixture wet engraving 20s, remove the Ag layer; The mass-to-fraction ratio of nitric / phosphate / acetate mixture is 30%:30%:40%.

[0046] 3)、C 4 F 8Deposition passivation layer, process parameters: time 30s, power supply power 500W, C 4 F 8 Flow rate 20sccm, pressure 10mt, temperature 50 °C. C is deposited on the surface of the photoresist and on the surface of the ITO below the exposed Ag surface area 4 F 8 Passivation layer, deposition C 4 F 8 Used to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com